Design method of ultra-thin lens used for LED

A design method and technology of LED light source, applied in lighting and heating equipment, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve problems such as affecting the use of lenses, increasing light loss, etc. Astigmatism reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The design method of the ultra-thin lens for LED of the present invention will be described in more detail with reference to the accompanying drawings.

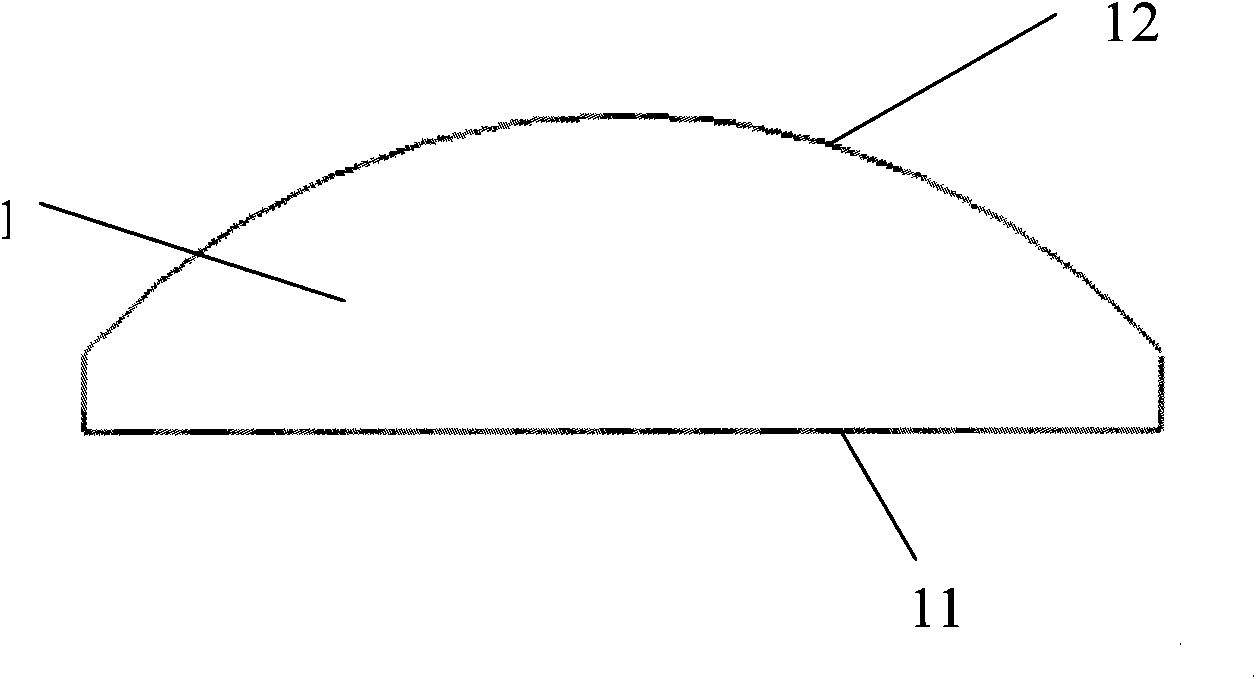

[0037] Such as figure 1 , first design the original lens 1 according to the specific optical requirements. In this embodiment, it is assumed that the incident surface 11 of the lens is a plane, and the outgoing surface 12 is assumed to be an ideal curved surface. As for how to design the shape of the original lens, it is not within the scope of the technical solution disclosed in the present invention. In this embodiment, the shape of the exit surface 12 is designed to achieve the purpose of thinning the lens.

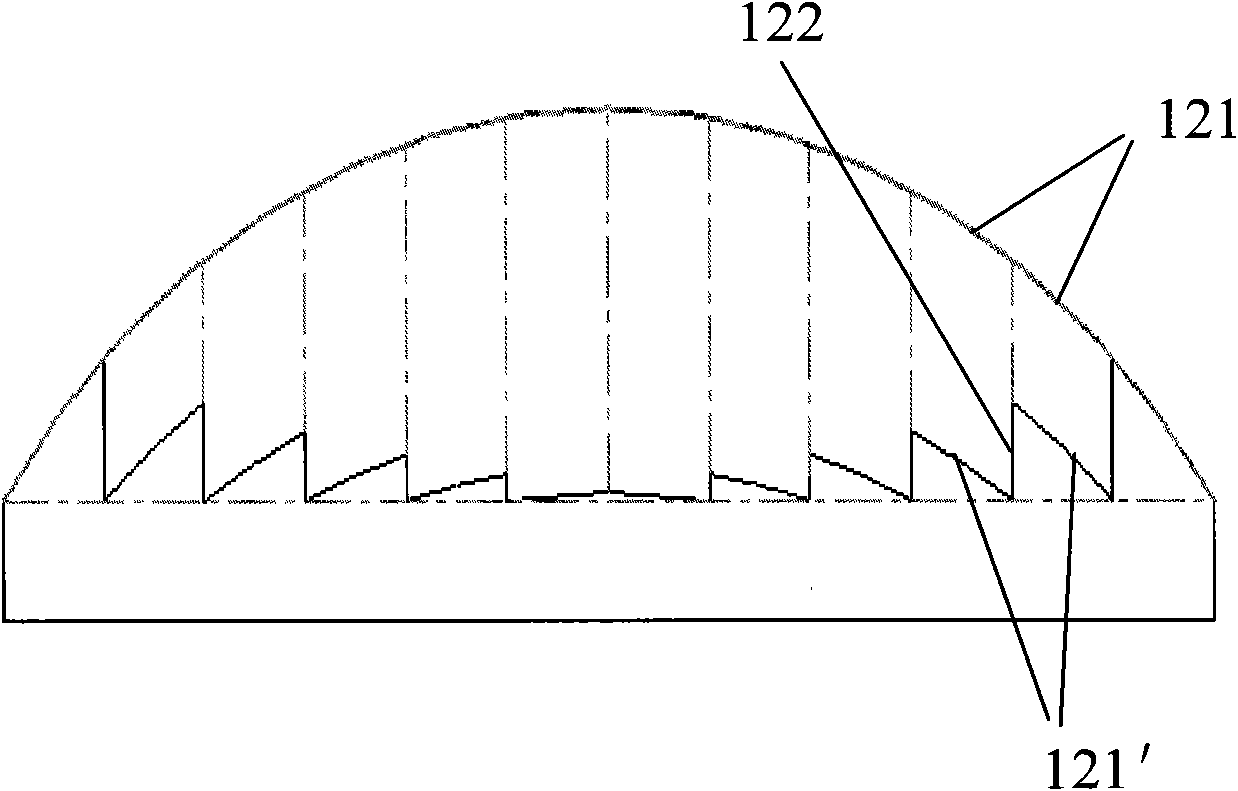

[0038] figure 2 is the prior art figure 1 A schematic diagram of a method for designing a section of the original lens 1 passing through the optical axis. The method is to first divide the exit surface 12 into a plurality of small curves 121, and then translate the multiple small curves 121 along the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com