Method of making inverted trapezoidal cross-section structure by S18 series of positive photoresist

A positive photoresist, photoresist technology, applied in optics, opto-mechanical equipment, photo-engraving process of pattern surface, etc., can solve the problems of light leakage, resolution reduction, etc., to protect the environment, improve accuracy, freedom great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

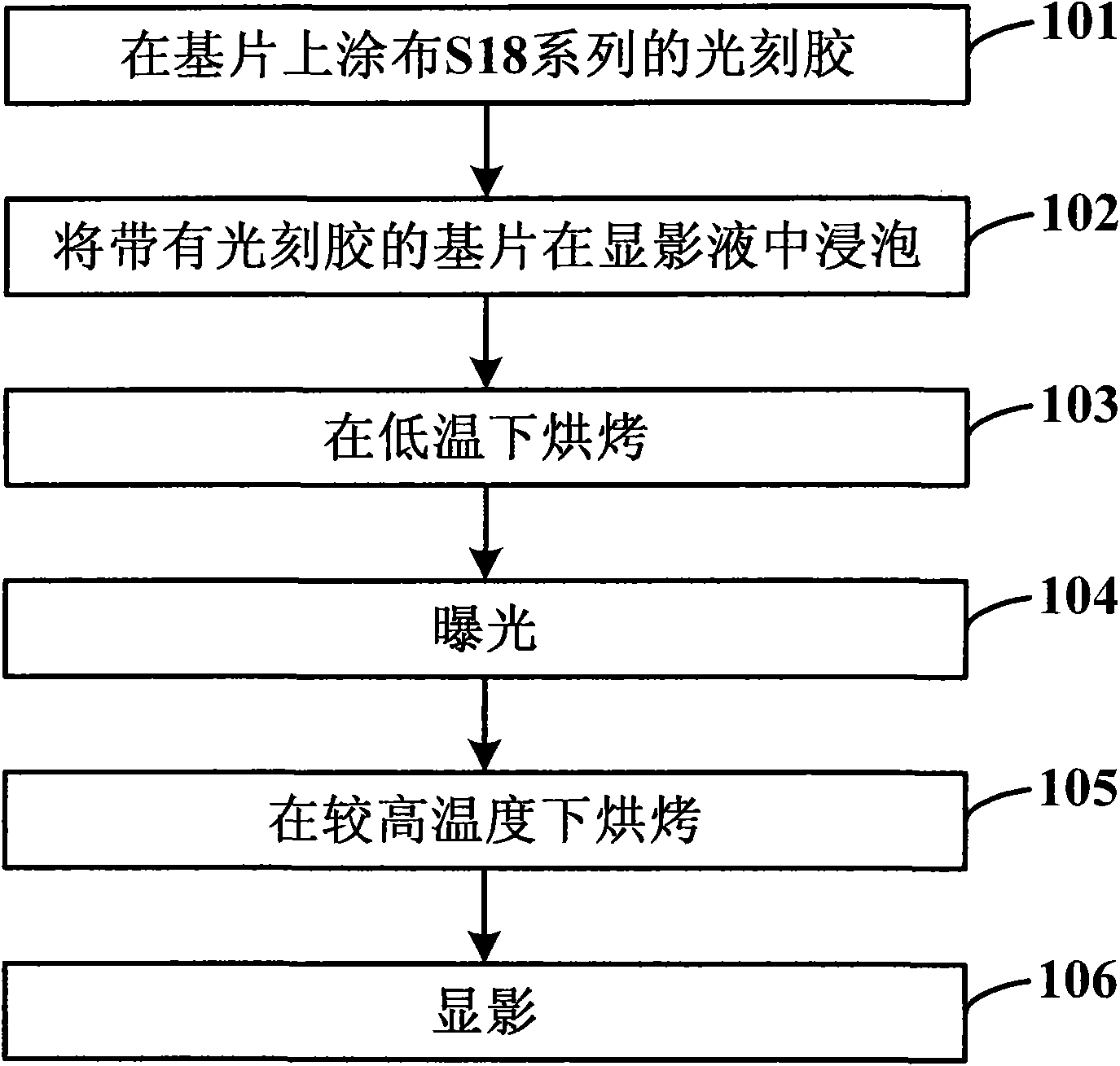

[0047] like figure 1 as shown, figure 1 A flow chart of a method for making an inverted trapezoidal cross-sectional structure provided by the present invention, the method includes the following steps:

[0048] Step 101: coating the photoresist of S18 series on the substrate;

[0049] Step 102: immersing the substrate with photoresist in a developing solution;

[0050] Step 103: baking at low temperature;

[0051] Step 104: exposure;

[0052] Step 105: baking at a higher temperature;

[0053] Step 106: developing.

[0054] The photoresist coated in step 101 above can be any photoresist of the S18 series, including photoresists of various types and thicknesses in this series, such as S1808, S1813, S1818, etc. The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com