Polyurethane elastomer as well as preparation method and usage thereof

A polyurethane elastomer and polymer technology, applied in applications, shoe soles, clothing, etc., can solve problems such as damage to the health of production operators, environmental pollution, and user health damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

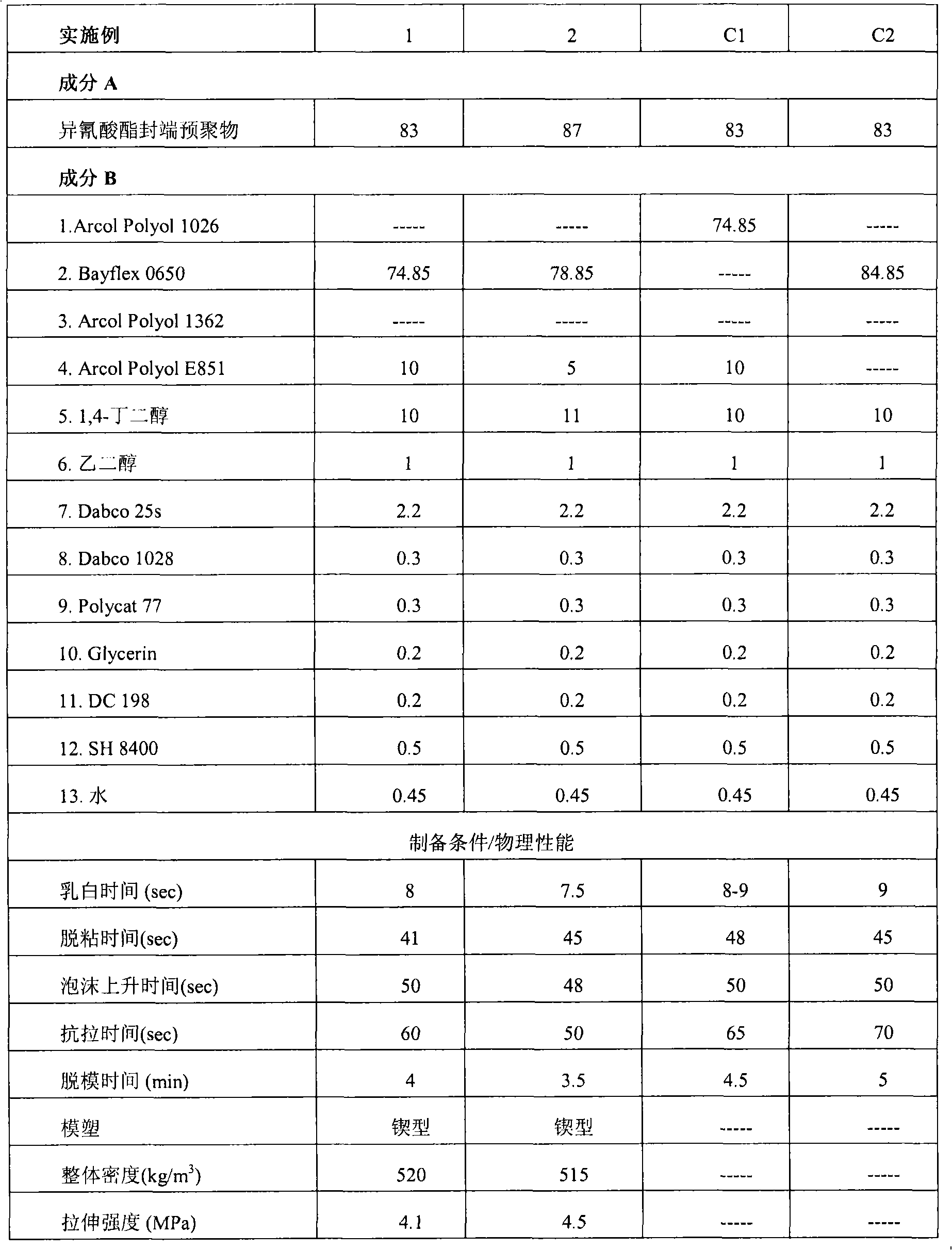

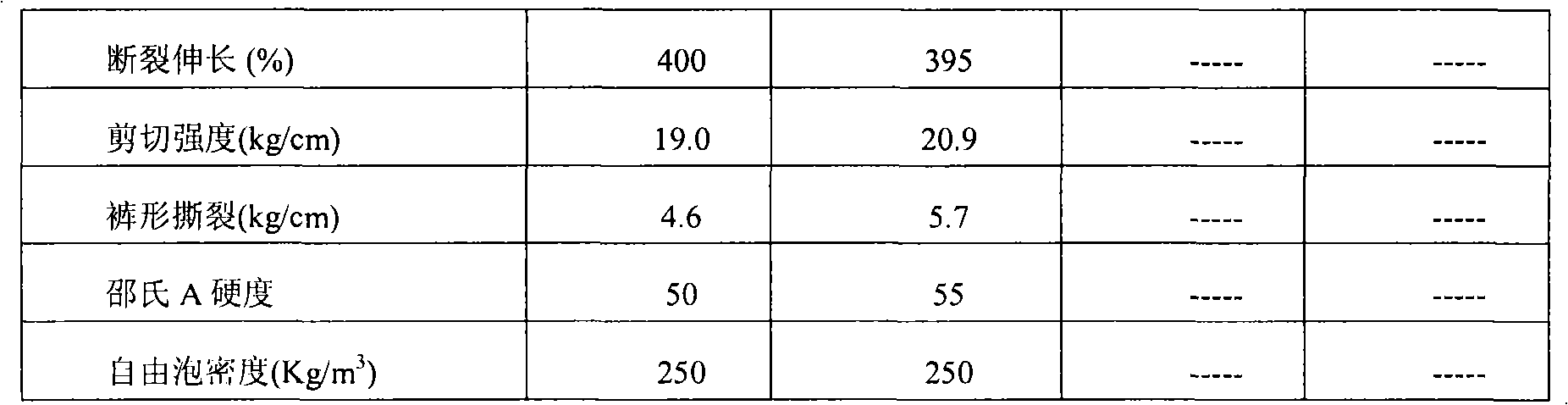

Embodiment 1 and comparative Embodiment C1

[0105] In Comparative Example C1, the traditional polyether polyol Arcol Polyol 1362 was selected to prepare the polyurethane elastomer, and the polyether polyol was 15% EO-terminated polyether polyol. Because the EO content in the polyether polyol is too low, the polyurethane foam produces fine cracks, and the desired polyurethane elastomer cannot be obtained.

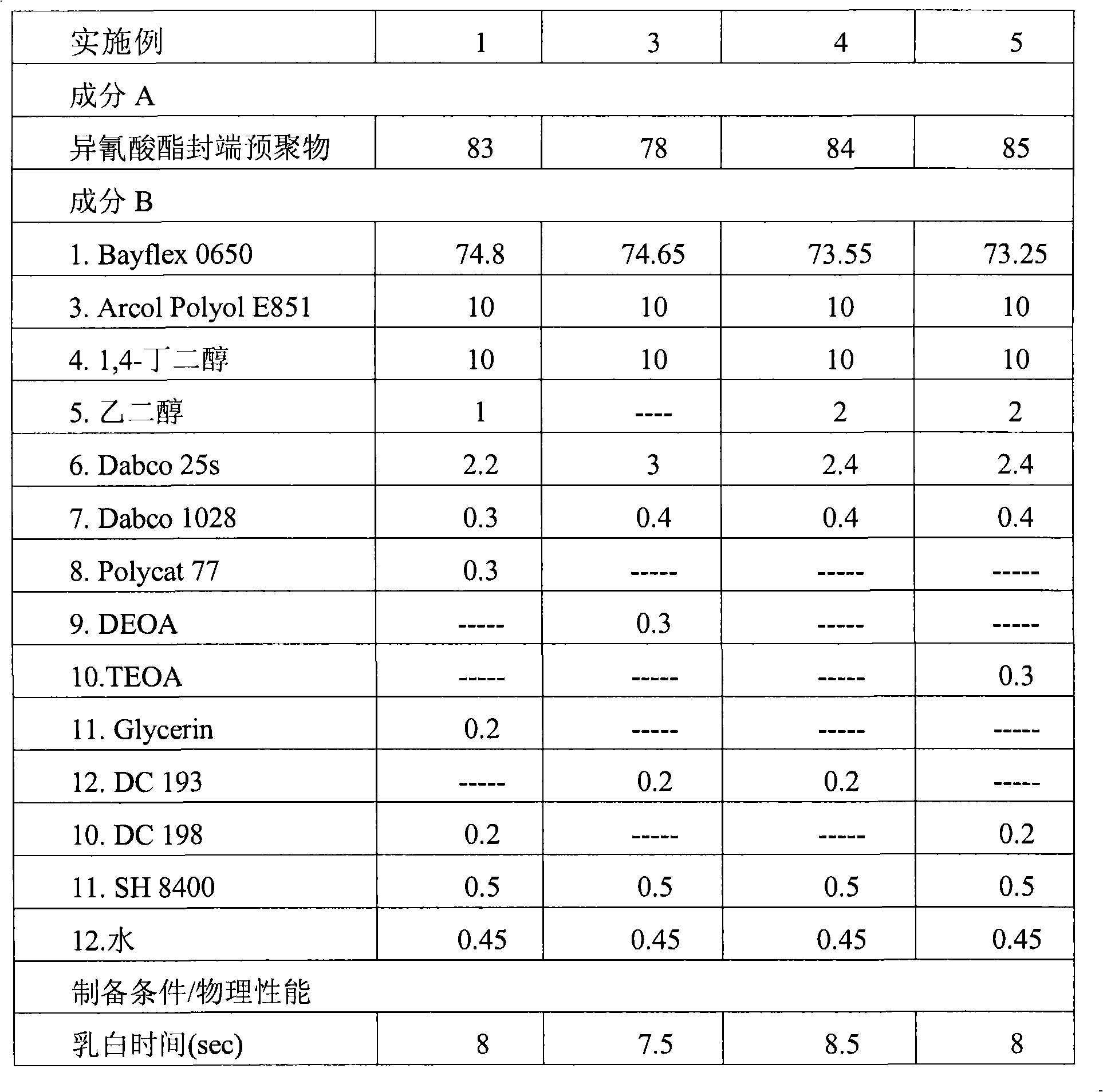

Embodiment 1

[0106] In Example 1, polyether polyol Bayflex 0650 was selected to prepare polyurethane elastomer, and the polyether polyol was 30% EO-terminated polyether polyol. Due to the appropriate content and reasonable dosage of EO in polyether polyol, no cracks appeared in polyurethane foam. It can be seen that although a metal catalyst is not used, the polyether polyol with a reasonable amount of EO content and the special ratio between it and the amine catalyst maintain the good physical properties of the polyurethane elastomer.

Embodiment 1 and comparative Embodiment C2

[0108] In comparative example C2, the polyether polyol Bayflex 0650 with an appropriate EO content was selected, but the polymer polyol Arcol Polyol E851 with an appropriate acrylonitrile-styrene copolymer content was not used at the same time, resulting in small cracks in the polyurethane foam and failure to obtain Desired polyurethane elastomer.

[0109] In Example 1, polyether polyol Bayflex 0650 with appropriate EO content and polymer polyol Arcol Polyol E851 with appropriate acrylonitrile-styrene copolymer content were selected to prepare polyurethane elastomer, and no cracks appeared in the polyurethane foam. It can be seen that although no metal catalyst is used, the special ratio between polyols and between polyols and amine catalysts maintains the good physical properties of polyurethane elastomers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com