Dry-type completely automatic control cold slag machine

A slag cooler, dry technology, applied in the field of dry automatic control slag cooler, can solve problems such as inability to work, reduce slag discharge rate, insufficient reinforcement strength, etc., achieve fast cooling speed, prolong service life, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

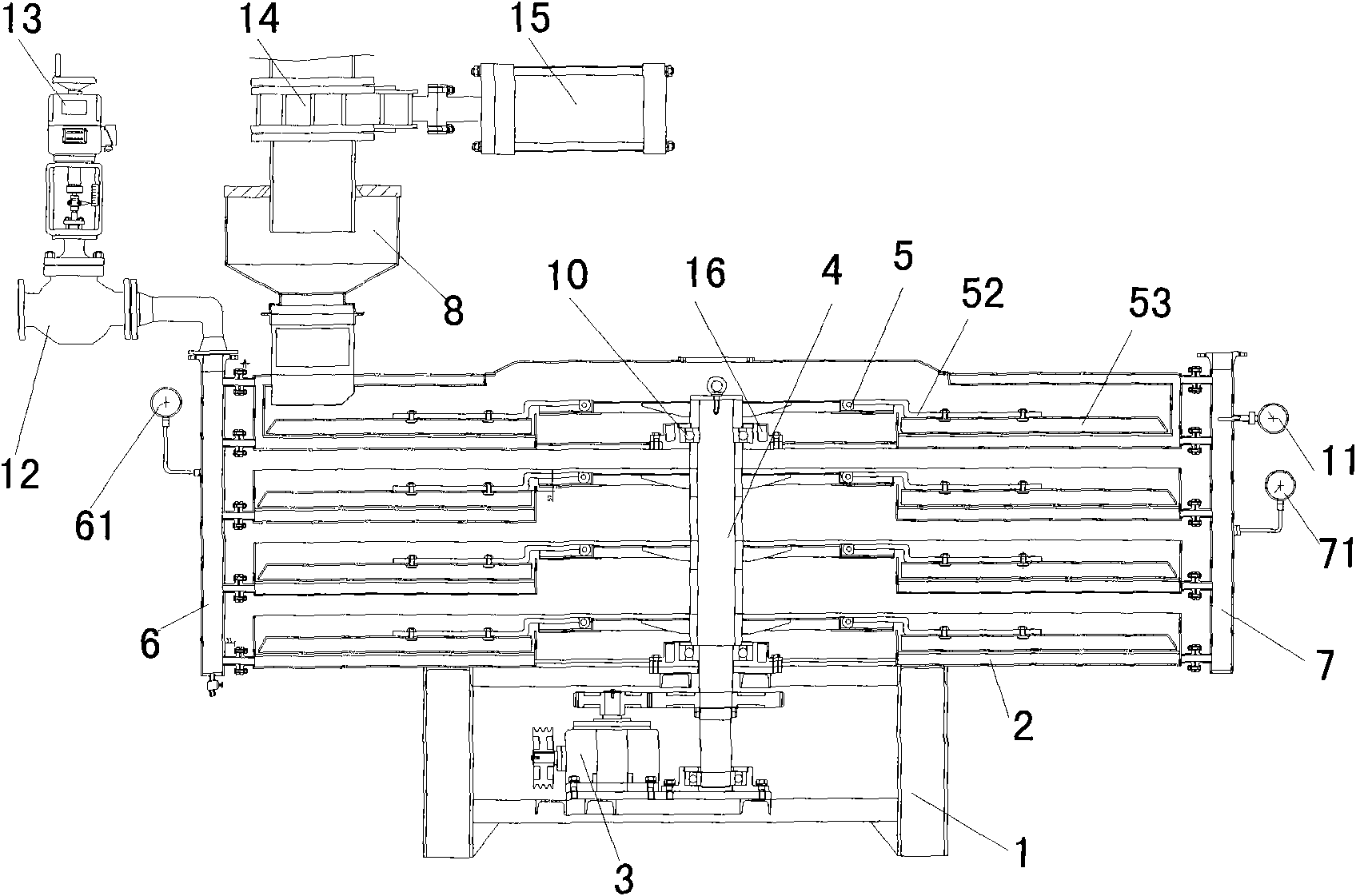

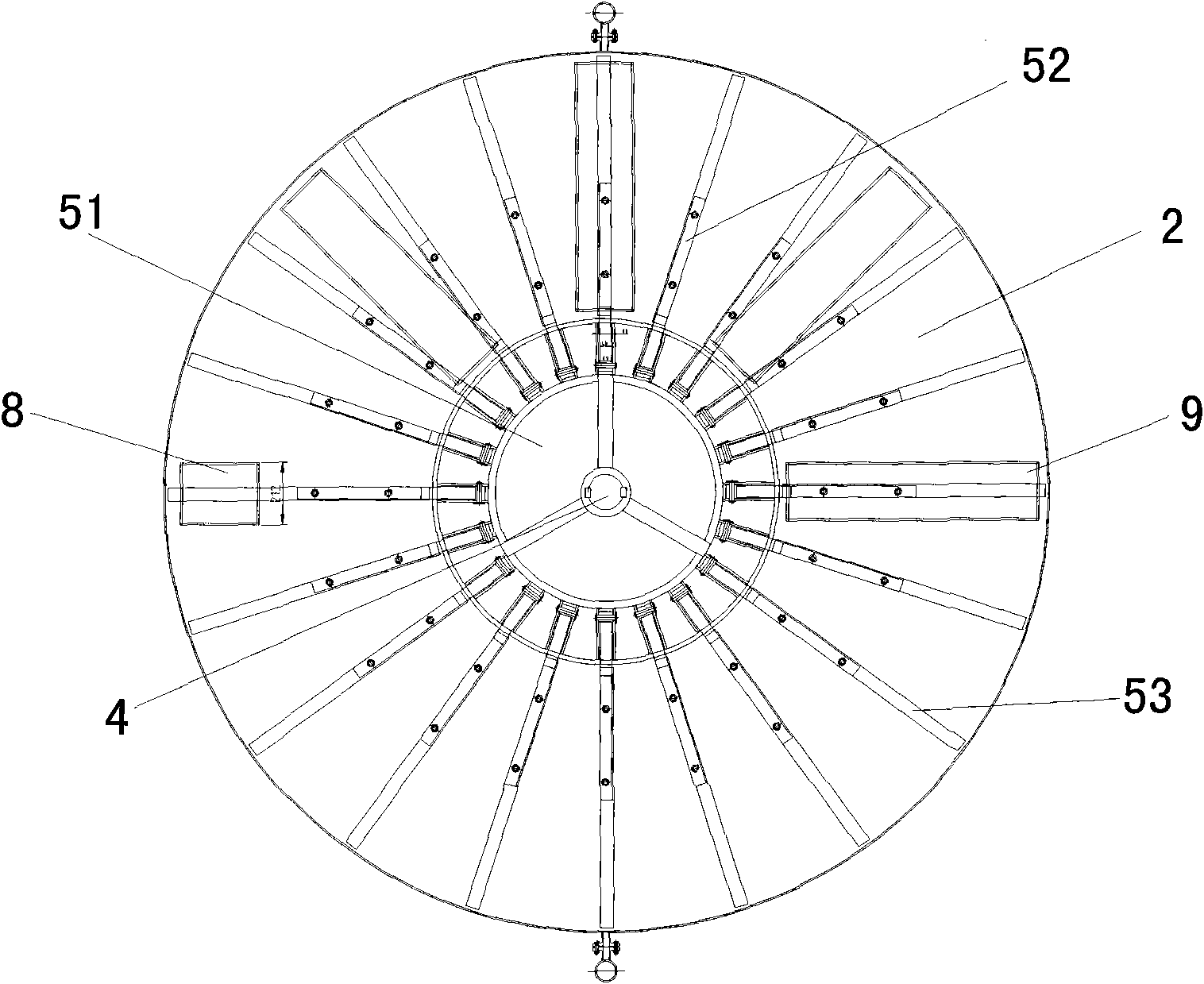

[0011] see figure 1 , with reference to figure 2 , the dry fully automatic control slag cooling machine of the present invention comprises a frame 1, a multi-layer ring groove 2 installed above the frame for transmitting ash, a motor transmission mechanism 3 installed in the frame, and a motor transmission mechanism The vertical shaft 4 connected to the transmission, the turntable scraper mechanism 5 connected with the vertical shaft and matched with the ring groove, the water inlet main pipe 6, the water outlet main pipe 7, the slag inlet 8, the slag outlet 9, the ventilation and heat dissipation mechanism (not shown in the figure) and automatic control mechanism. The automatic control mechanism includes a central controller (not shown in the figure), a water temperature transmitter 11 connected to the central controller by telecommunication, a water inlet control mechanism and a slag inlet control mechanism. The water temperature transmitter 11 is installed on the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com