Environment friendly energy-saving smokeless stove

A technology for environmental protection, energy saving, and stoves, which is applied in household stoves/stoves, lighting and heating equipment, solid heating fuels, etc., can solve the problems of insufficient energy saving and emission reduction, incomplete combustion, and high smoke concentration, and achieve thermal efficiency Improvement, convenient operation, and improved coal-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

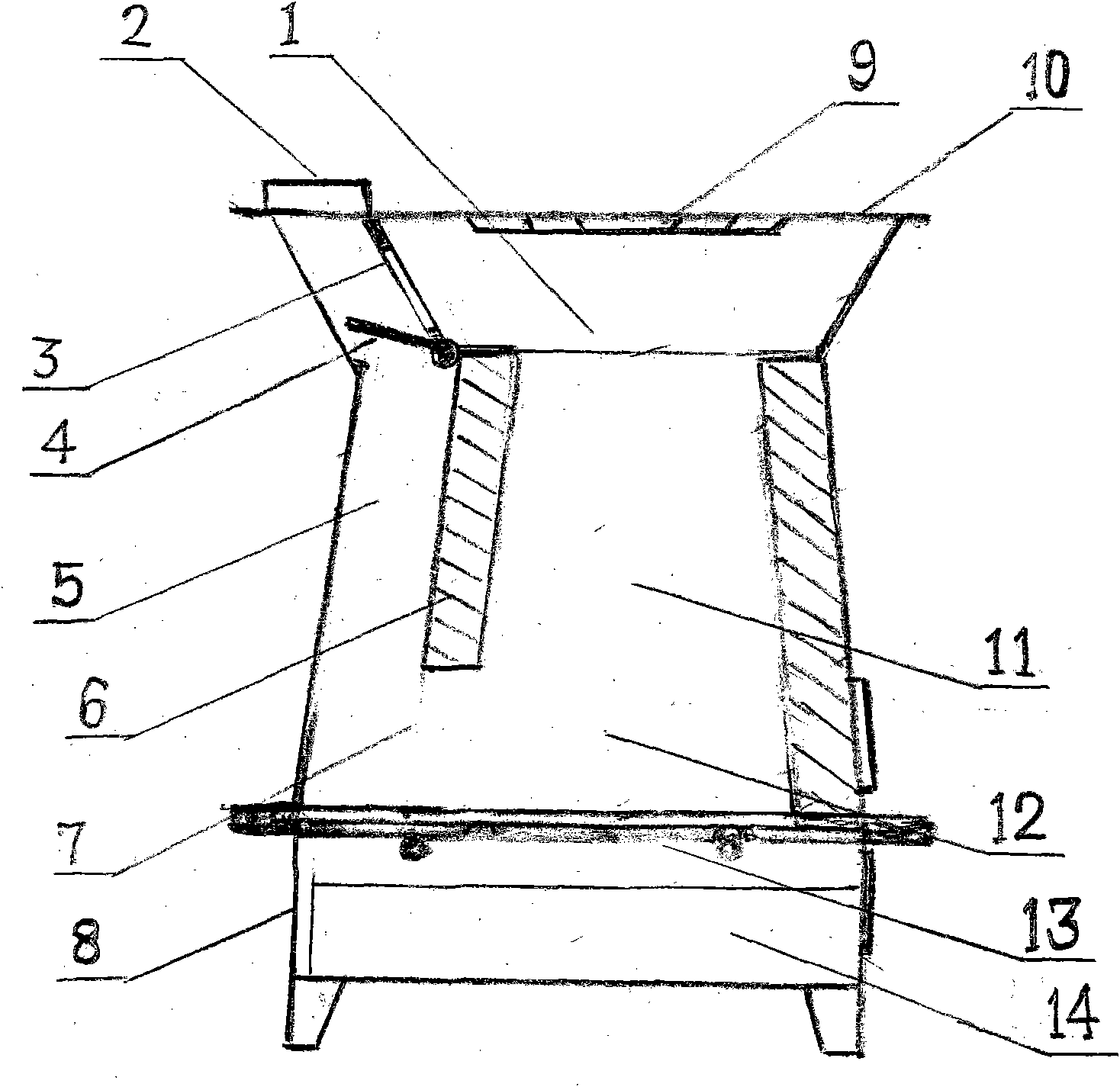

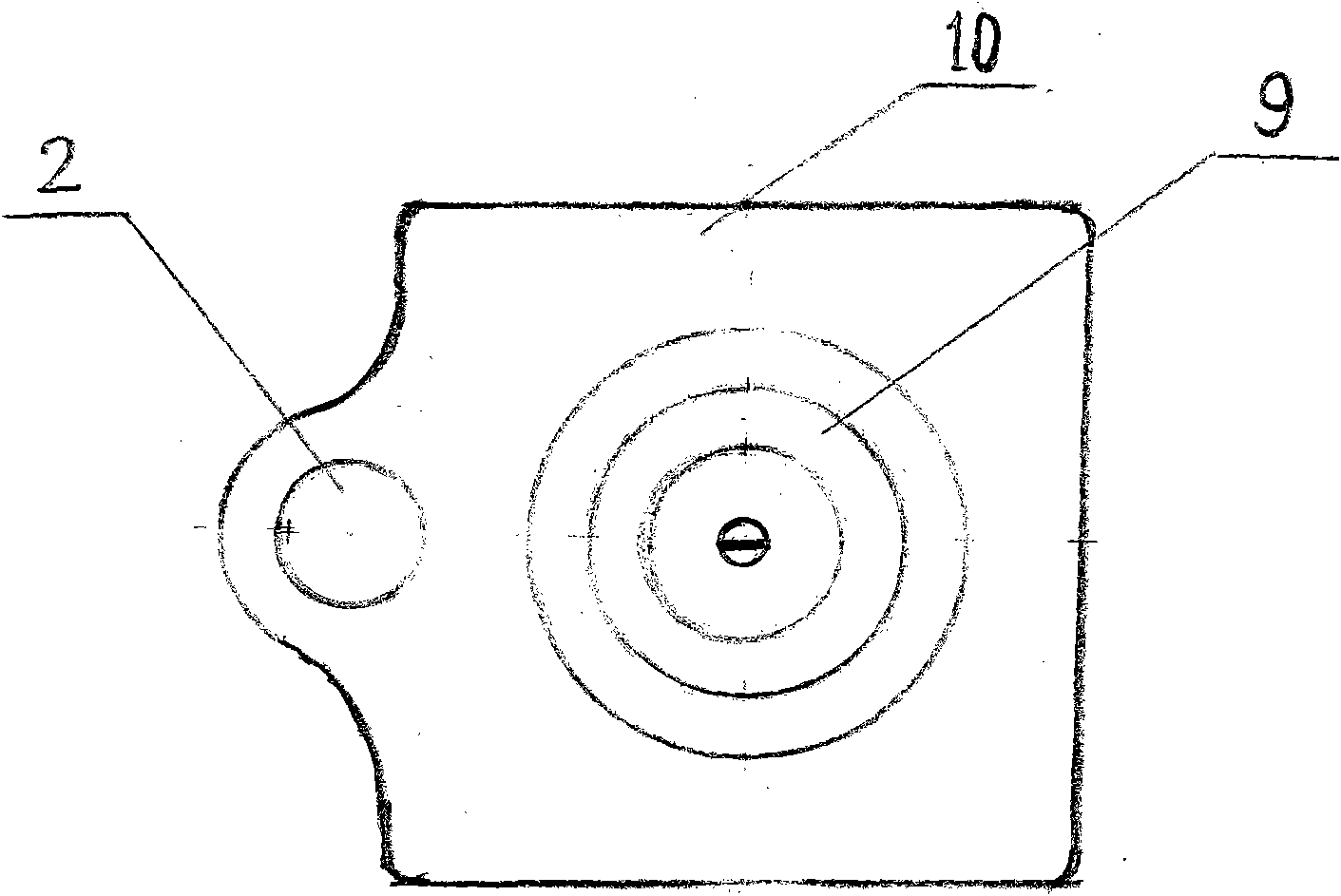

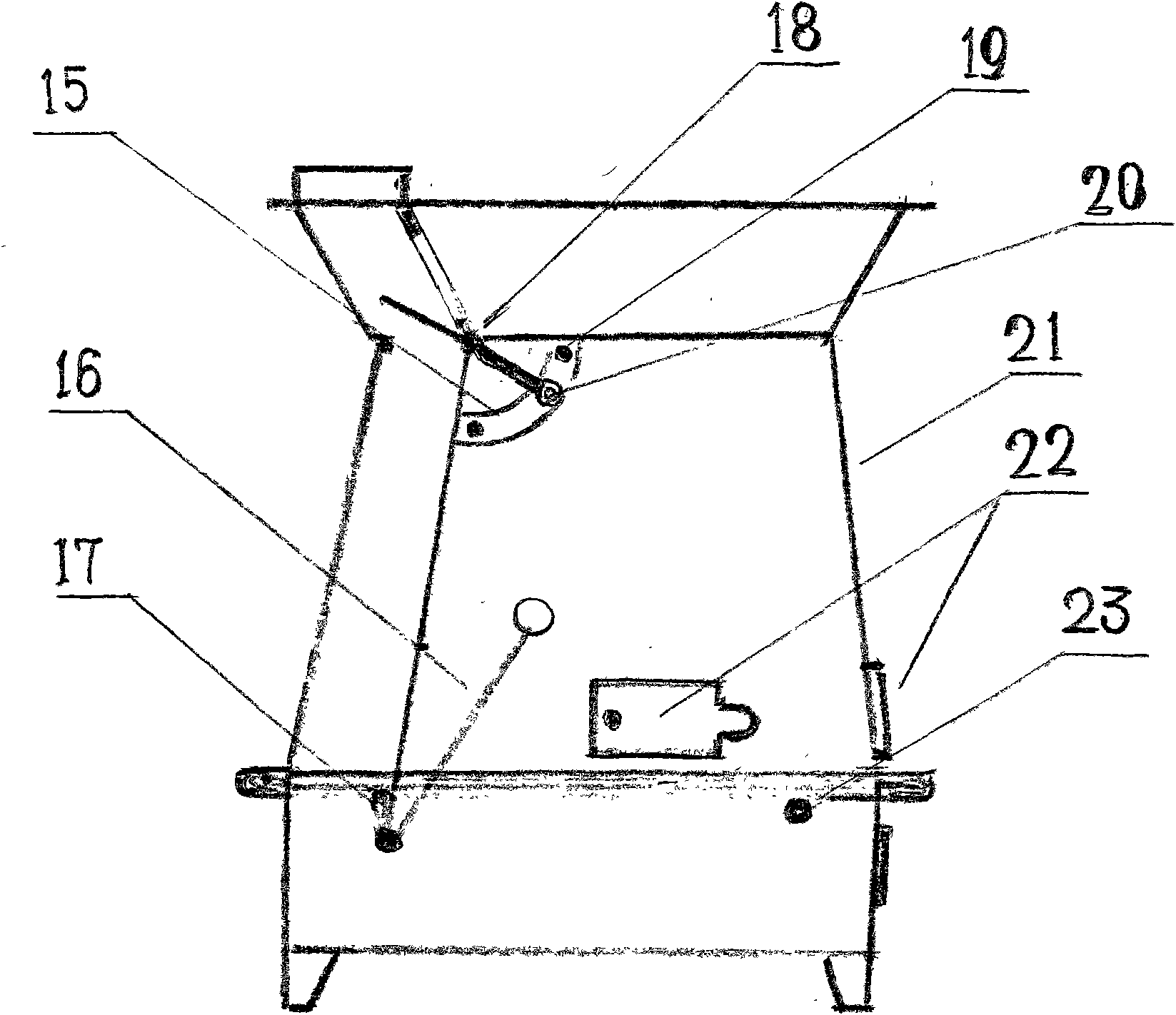

[0015] With reference to the accompanying drawings, the present invention includes a furnace body 21, a furnace pan 10, bituminous coal passes through a furnace ring 9, a coal filling port 1, enters a coal storage area 11, and burns downward in a combustion area 12 in a refractory combustion zone 6 after being ignited. , called back burning, the flame after combustion enters the rear flue 5 through the lower return fire outlet 7, and is discharged into the atmosphere through the external chimney through the flame exhaust port 2.

[0016] With reference to the accompanying drawings, when cooking, after a large amount of soot is burned out, the front and back fire conversion baffle plate 4 is used to seal the rear flue, and the upper and back fire flame outlet 3 is opened, and the flame goes up from the combustion zone through the coal inlet 1, and goes straight into it. At the bottom of the stove ring 9 cooking utensils in the middle of the stove pan 10, the meals are fired, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com