Method and mould for producing first outer-packing vacuum arc extinguishing chamber of phase post of circuit breaker element

A technology of vacuum interrupter and manufacturing method, which is applied to high-voltage air circuit breakers, electrical components, circuits, etc., can solve the problems of air gap shrinkage stress, poor external insulation performance, etc., and achieve improved yield, high insulation performance, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

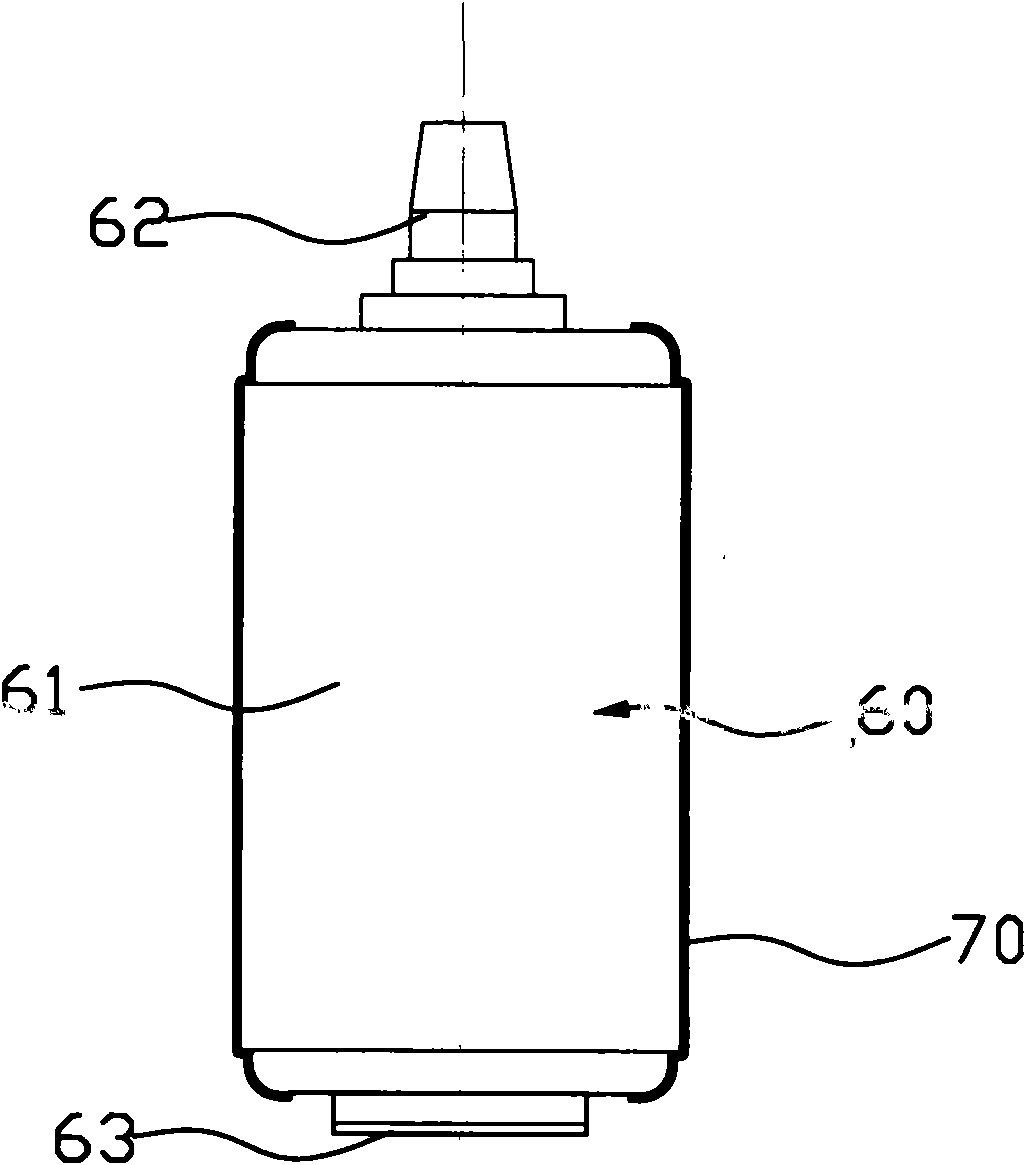

[0050] Please refer to figure 1 , it includes a vacuum interrupter 60, a primary package 70; the vacuum interrupter 60 includes a vacuum chamber 61, a moving end contact 62 and a static end contact 63; the primary package 70 is a silicone rubber buffer layer, it Wrap tightly around the vacuum interrupter 60 .

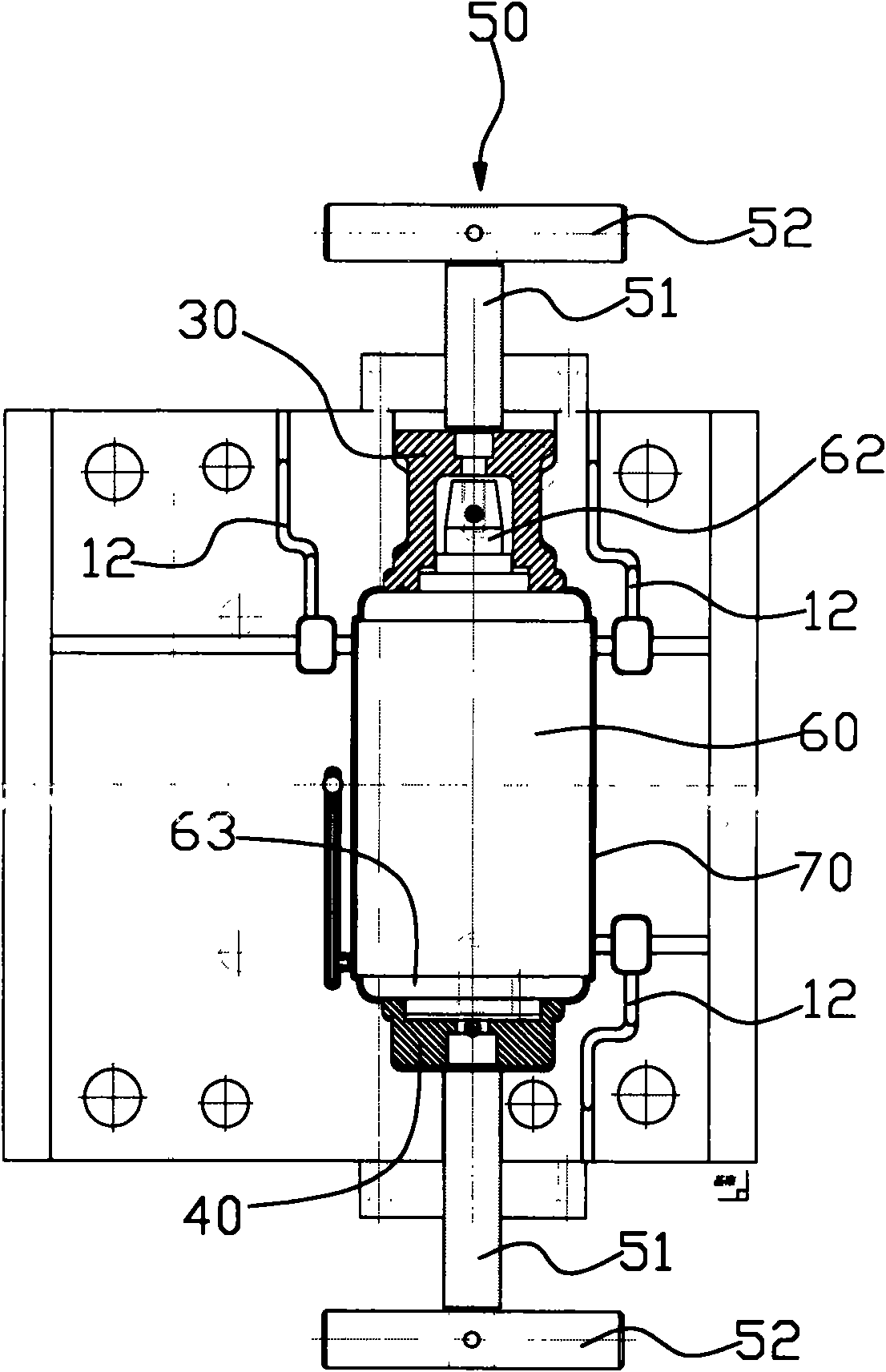

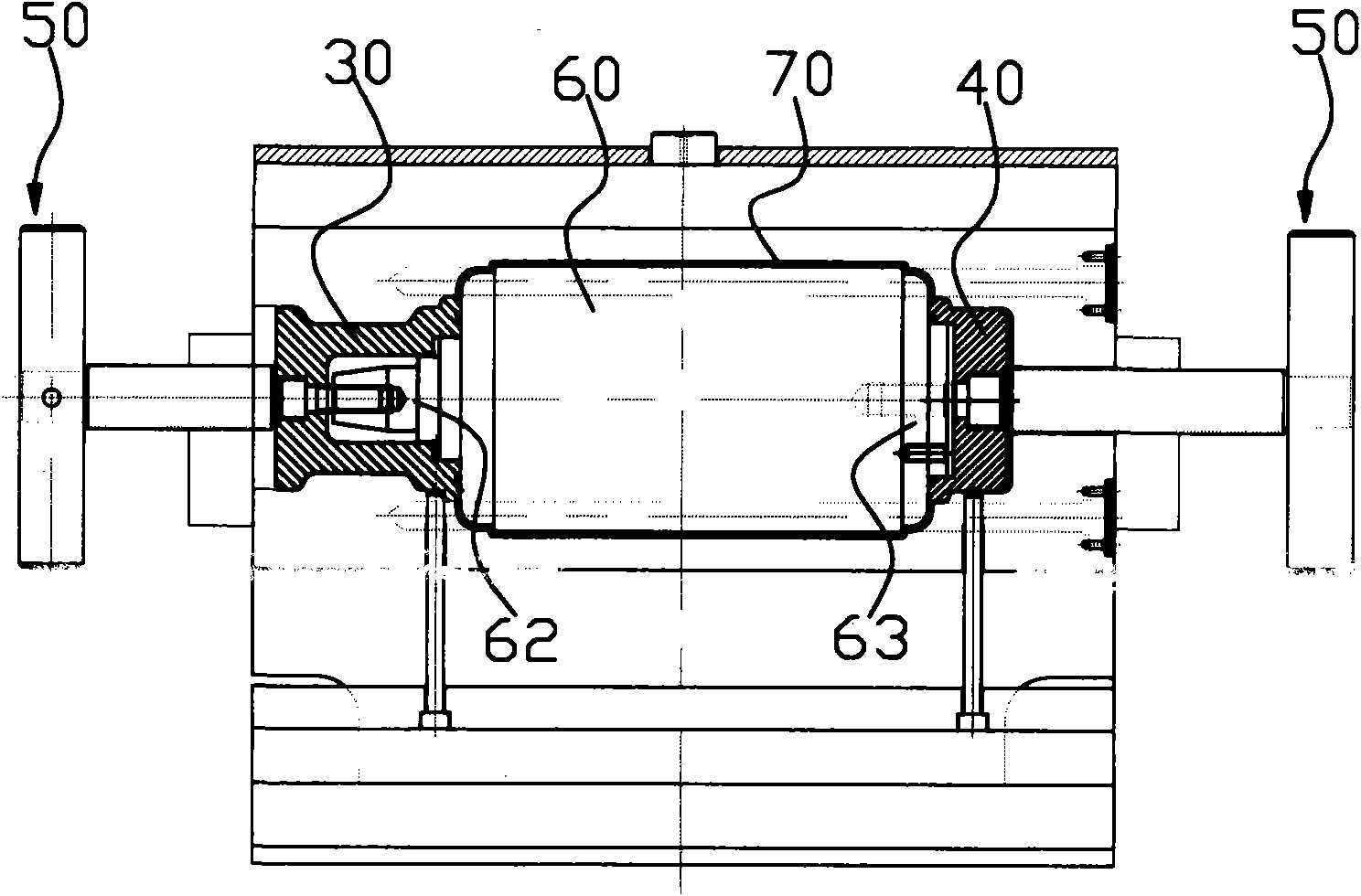

[0051] A manufacturing mold for a circuit breaker component outsourcing vacuum interrupter, please refer to figure 2 as well as image 3 , which includes a first template 10 , a second template 20 , a movable die head 30 , a static die head 40 and two handles 50 .

[0052] Please check Figure 4 , the first template 10 is provided with a first cavity 11 and an injection channel 12 . Please check Figure 5 , the second template 20 is provided with a second cavity 21 . Wherein, a clamping mechanism is provided between the first template 10 and the second template 20, and the clamping structure can be locked and released. combine. Please check figure 2 , image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com