Nano-material surface-catalyzed luminescent micro-sensor

A micro-sensor and nanomaterial technology, applied in chemiluminescence/bioluminescence, analysis by chemical reaction of materials, etc., can solve the problem of poor stability and reproducibility of luminescence signal, affecting the accuracy of quantitative analysis, and broadening of luminescence signal curve and other problems, to achieve the effect of improved resolution and detection sensitivity, rapid response time, and shortened response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

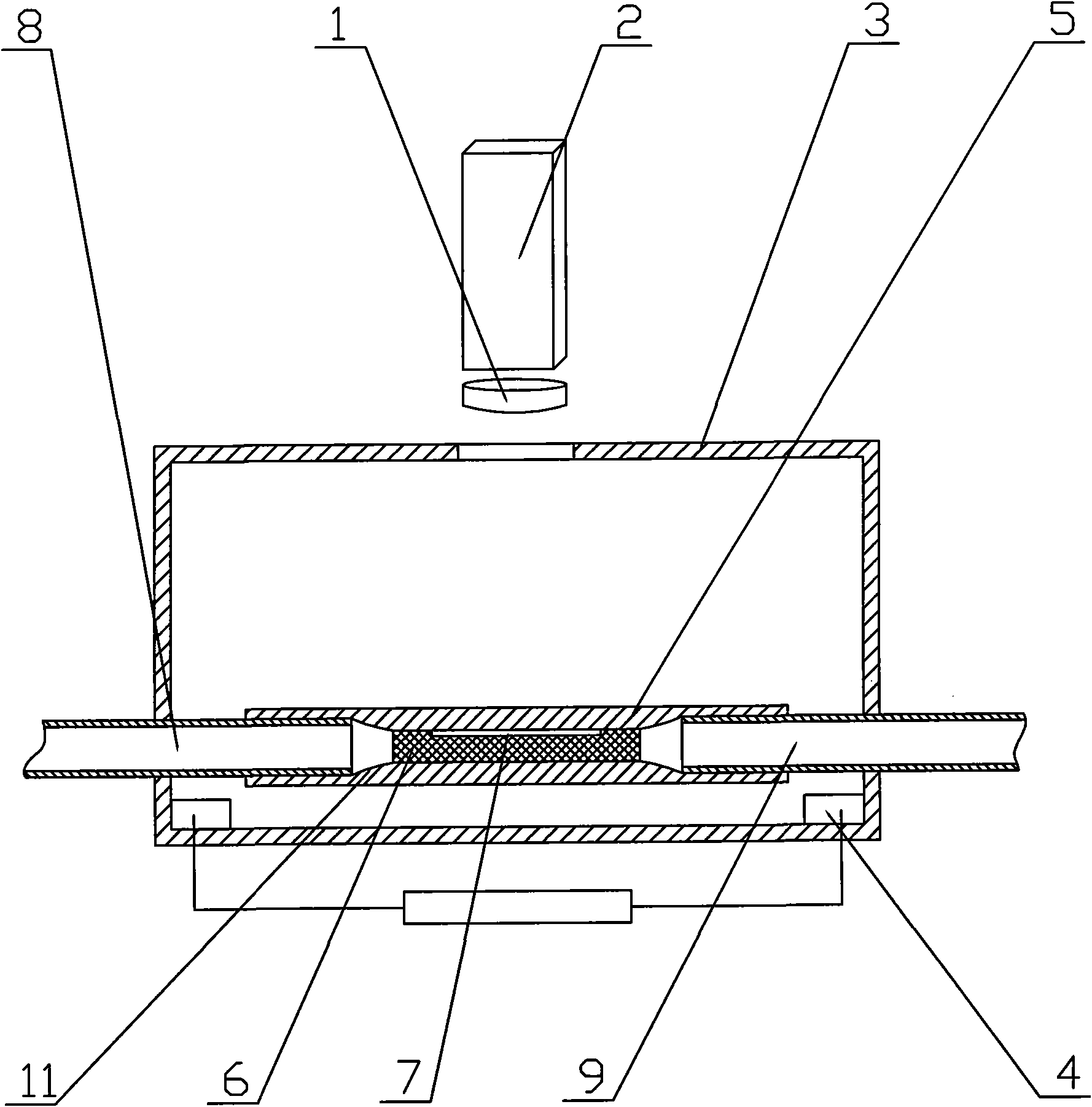

[0015] Such as figure 1 As shown: the material and the fixing method are the same as the optical filter or grating 1 and the photoelectric signal conversion device 2 of the prior art. The difference from the prior art is that a housing 3 is provided, and a heating element 4 is built in the housing 3 And the quartz capillary 5, the heating element 4 and the quartz capillary can be any one of the prior art, and the heating element 4 can be connected with the temperature control circuit, so that the temperature factors affecting the catalytic luminescence can be accurately controlled. The inner wall of the quartz capillary 5 is coated with a nanomaterial 6, but a part of the blank must be left, that is, the light-transmitting surface 7, such as the nanomaterial 6 is only coated on the lower side of the inner wall of the quartz capillary 5 or a blank is left on the upper side. . The light-transmitting surface 7 is arranged opposite to the optical filter or the grating 1 , and the...

Embodiment 2

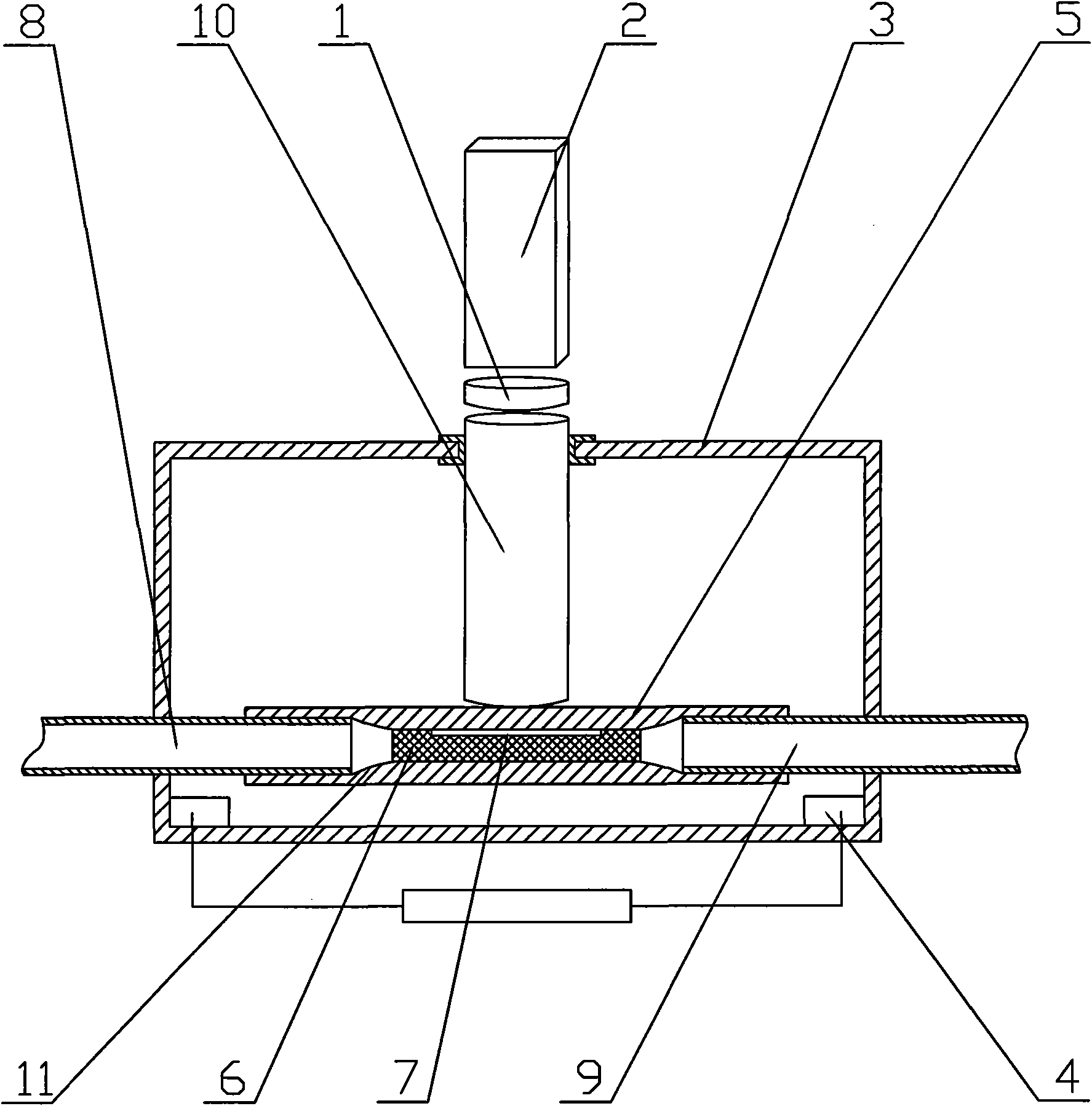

[0017] Such as figure 2 Shown:

[0018] The basic structure is the same as that of Embodiment 1. The difference from Embodiment 1 is that in order to avoid the loss of optical signals and the interference of stray light, a light-conducting element 10 is placed between the light-transmitting surface 7 and the filter or grating 1 . The diameter of the middle part of the quartz capillary 5 is smaller than that of both ends, and the diameter of the middle part is 0.1-0.75 mm. There is a smooth transition surface 11 between the middle part and both ends, and the nanomaterial 6 is coated on the middle part. For the convenience of the connection and disassembly of the quartz capillary 5 with the sample tube 8 and the vent tube 9, the sample tube 8 and the vent tube 9 are preferably capillaries, and the polyimide coating on the outside of the capillary can ensure tightness. Inserted at both ends of the quartz capillary 5, the light conducting element 10 is an optical fiber.

[0019...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com