Phase-locked axisymmetric folding combined carbon dioxide laser

A carbon dioxide, laser technology, applied in lasers, laser devices, laser parts and other directions, can solve problems such as difficult to improve, irrelevance, output power limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] specific implementation plan

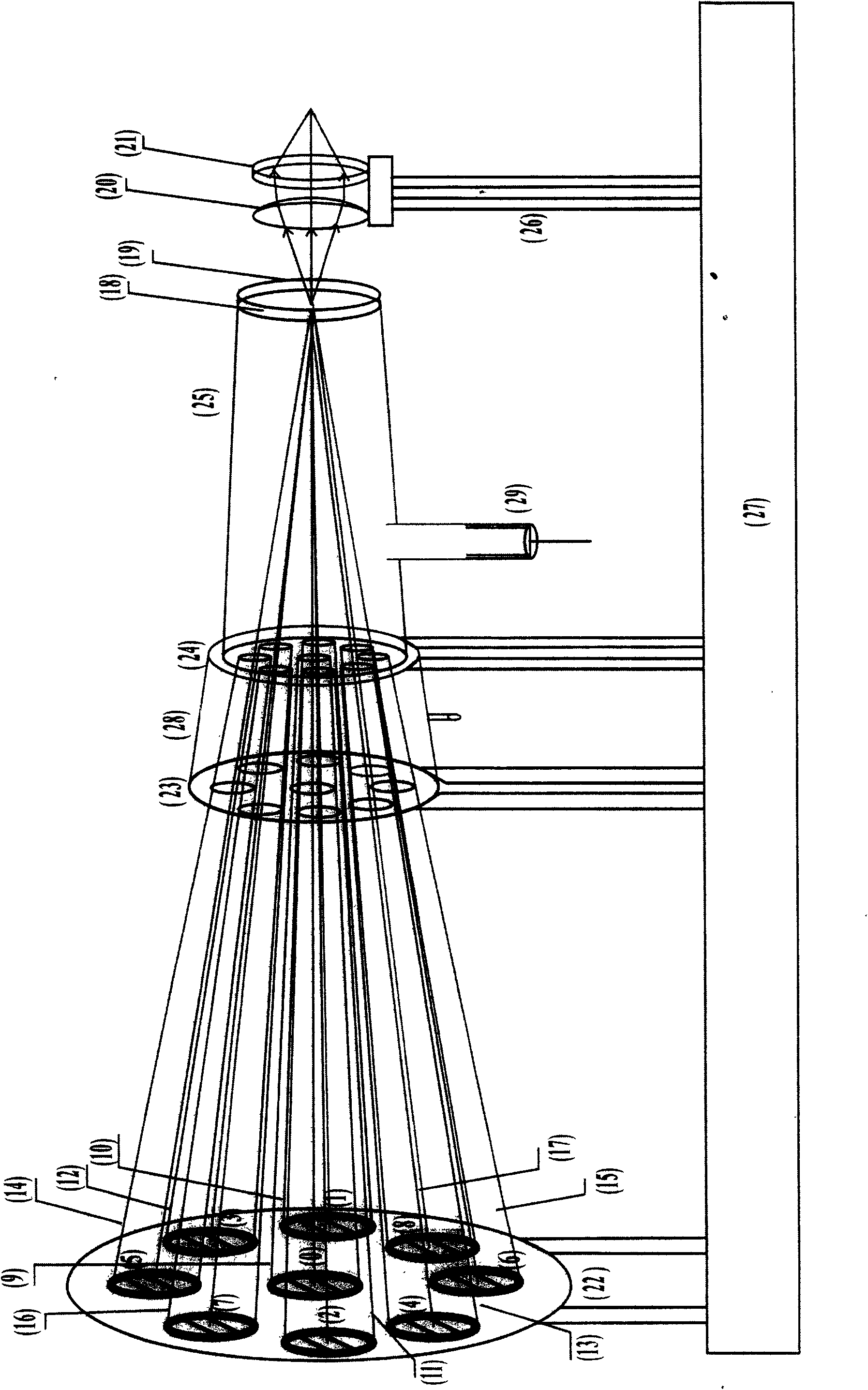

[0007]The core lines of each pair of symmetrically placed discharge tubes intersect at the center point of the inner surface of the output mirror 18, and the inner ends of the output mirror 18 are very close to each other. These discharge tubes and the discharge tubes placed on the shaft are all inserted in a fixed circle. In the one-to-one corresponding round holes of the disc brackets 22, 23, 24, and extend about 1 cm in the direction of the output mirror at 24, the gap between the outer edge of each tube and the corresponding round holes of 22, 23 is about 0.5 mm, Elastic fixation is adopted, and 24 is a disc support made of a stainless steel substrate. Each corresponding hole is connected with a Koval tube, and each Ko valve tube is connected to a discharge tube through a transition joint. The left end of the output mirror support 25 is vacuum-tightly connected, and the right end of the round table support is equipped with an output mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com