Printed circuit board and method for its production

A printed circuit, printed circuit board technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve problems such as total module failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

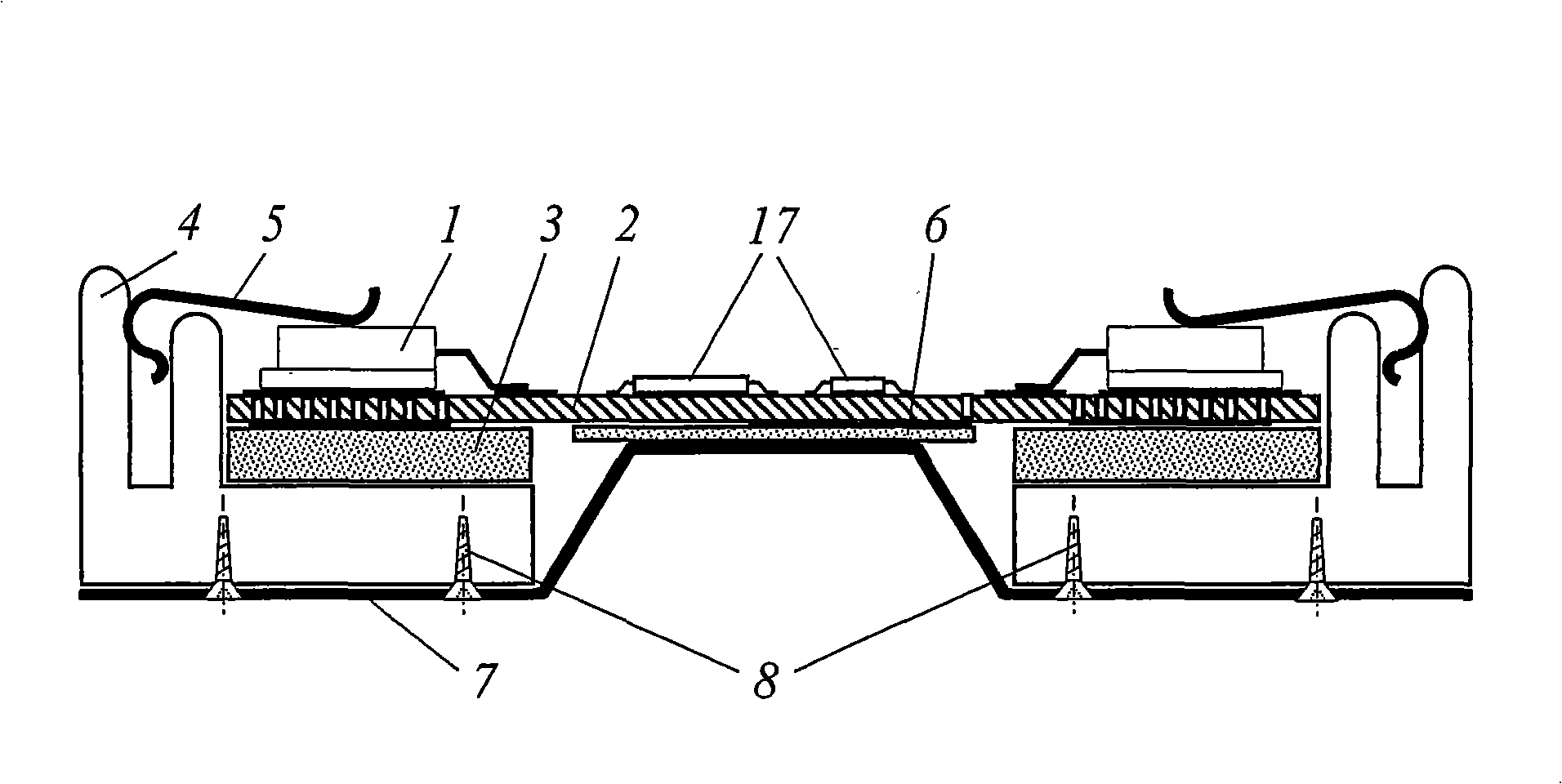

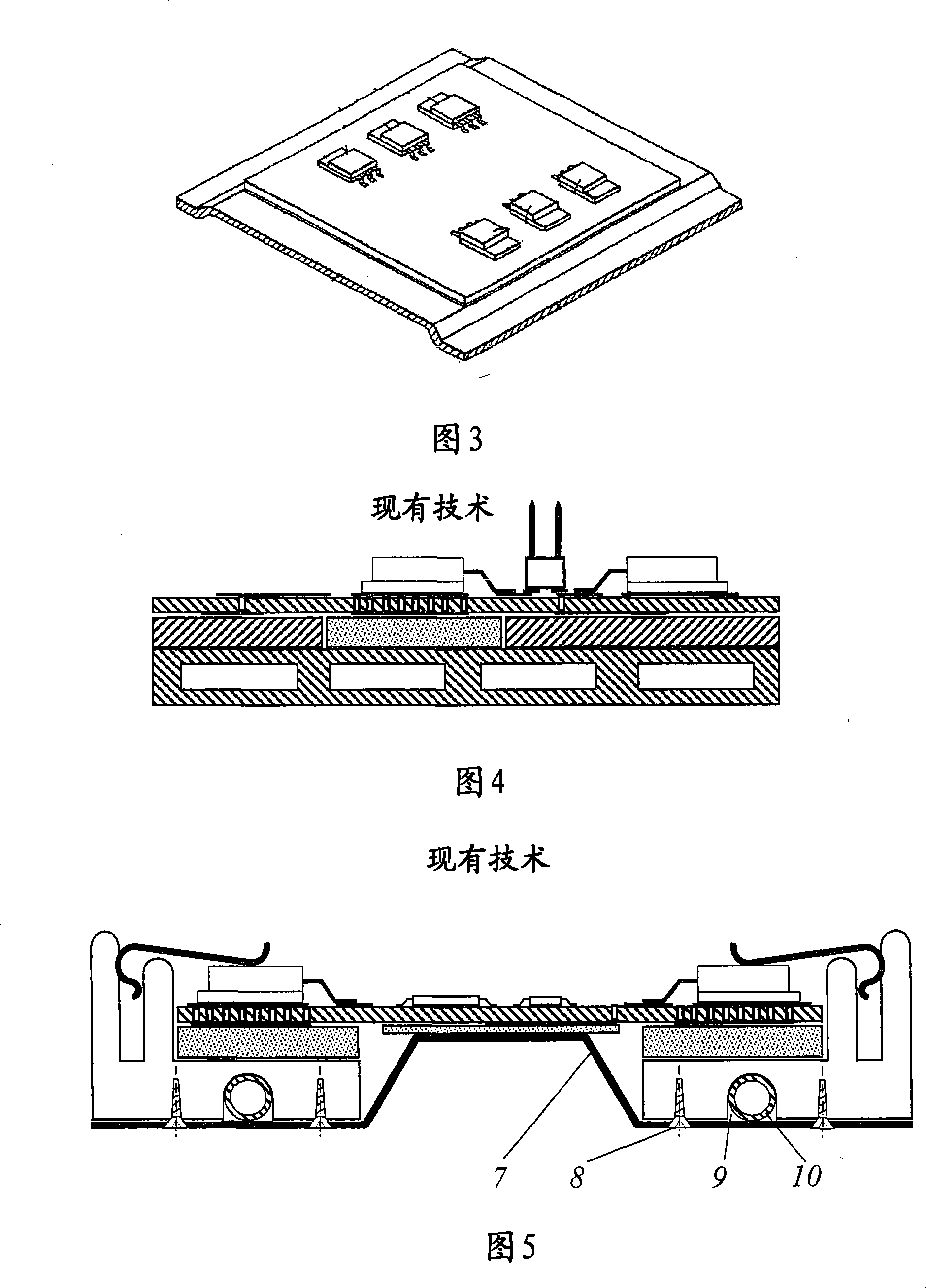

[0044] figure 1 A first embodiment of a printed circuit unit according to the invention (hereinafter also referred to as a power module or simply a module) is shown, which can be produced, for example, at least in part from commercially available components. in detail figure 1 Before the embodiments of the present invention, the embodiments of the present invention and their advantages will be generally described.

[0045] Some embodiments of a printed circuit unit according to the invention comprise a printed circuit board (which in some embodiments is discontinuous) and one or more cooling bodies (hereinafter also referred to as cooling (body) profiles). Solder surface-mountable components on the printed circuit board, the so-called SMD (Surface Mounted Device) components. The characteristic of SMD technology is that the components can be soldered directly on the printed circuit board. In some embodiments, in particular SMD components generating high thermal power are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com