High-power LED lamp based on heat pipe for thermal conductivity

A LED lamp, high-power technology, applied in the direction of semiconductor devices, lighting and heating equipment, components of lighting devices, etc., can solve the problems of large thermal resistance, small radiator contact surface, complex circuit design, etc., to achieve enhanced heat dissipation effect , expand the scope of use, improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

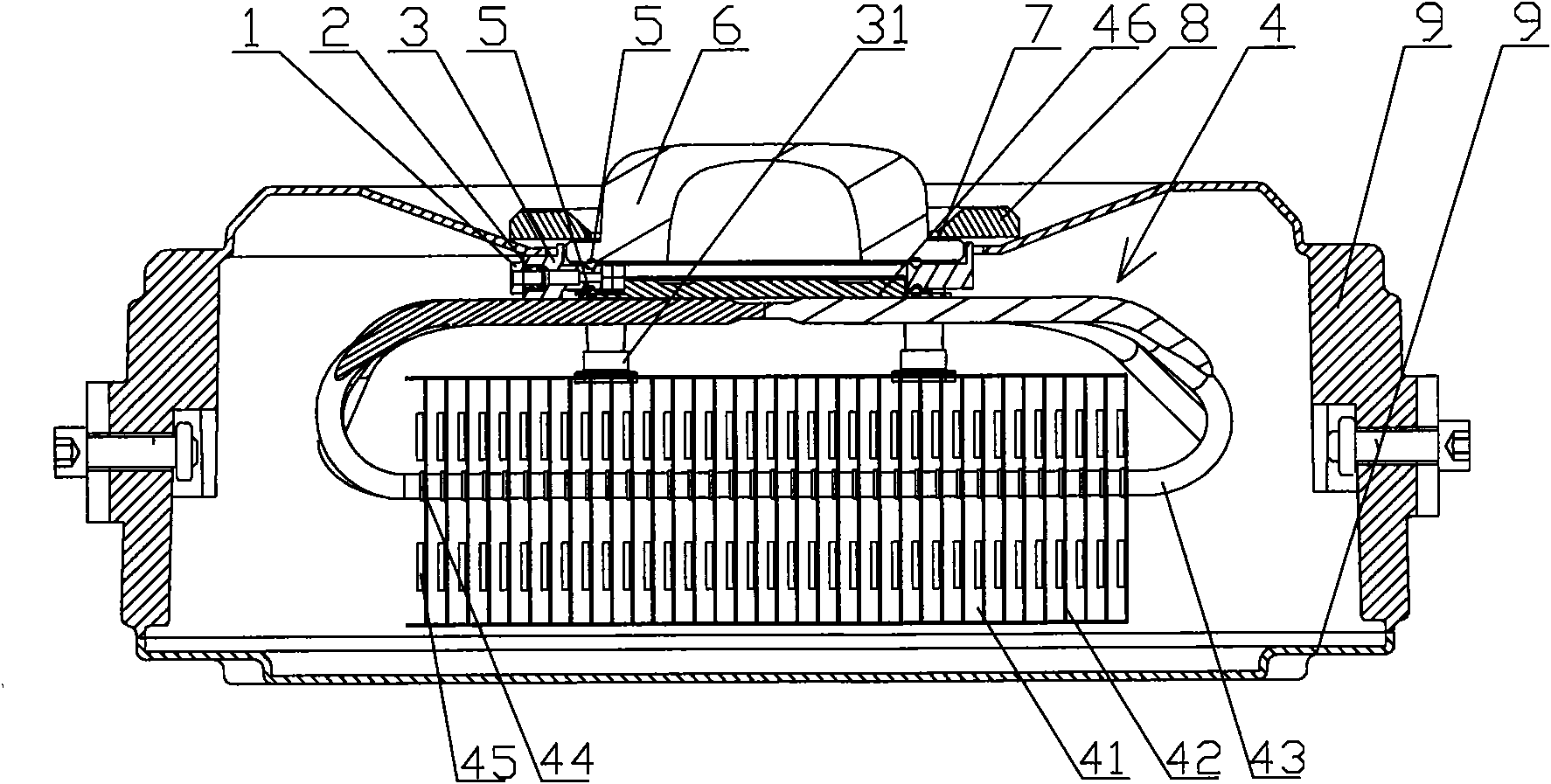

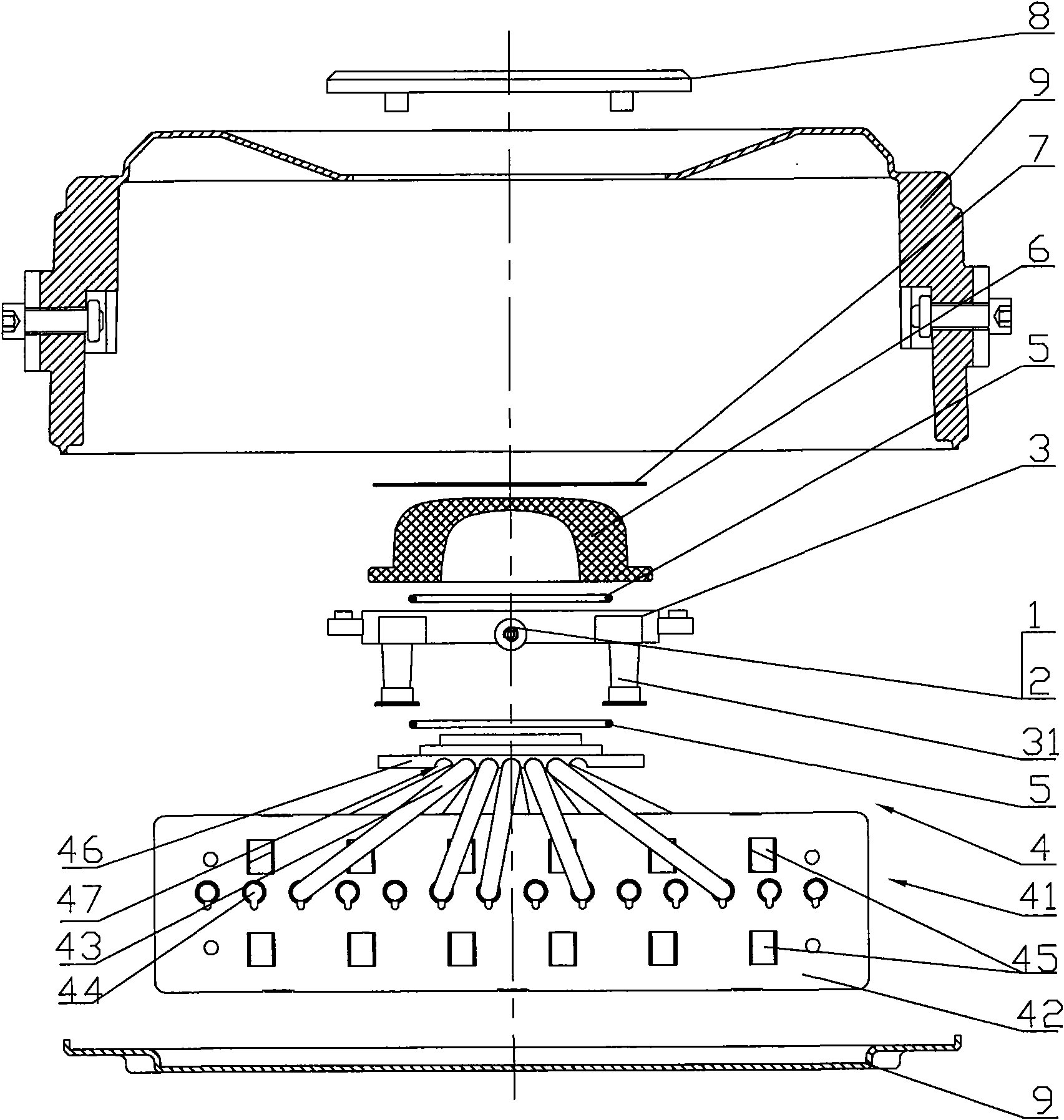

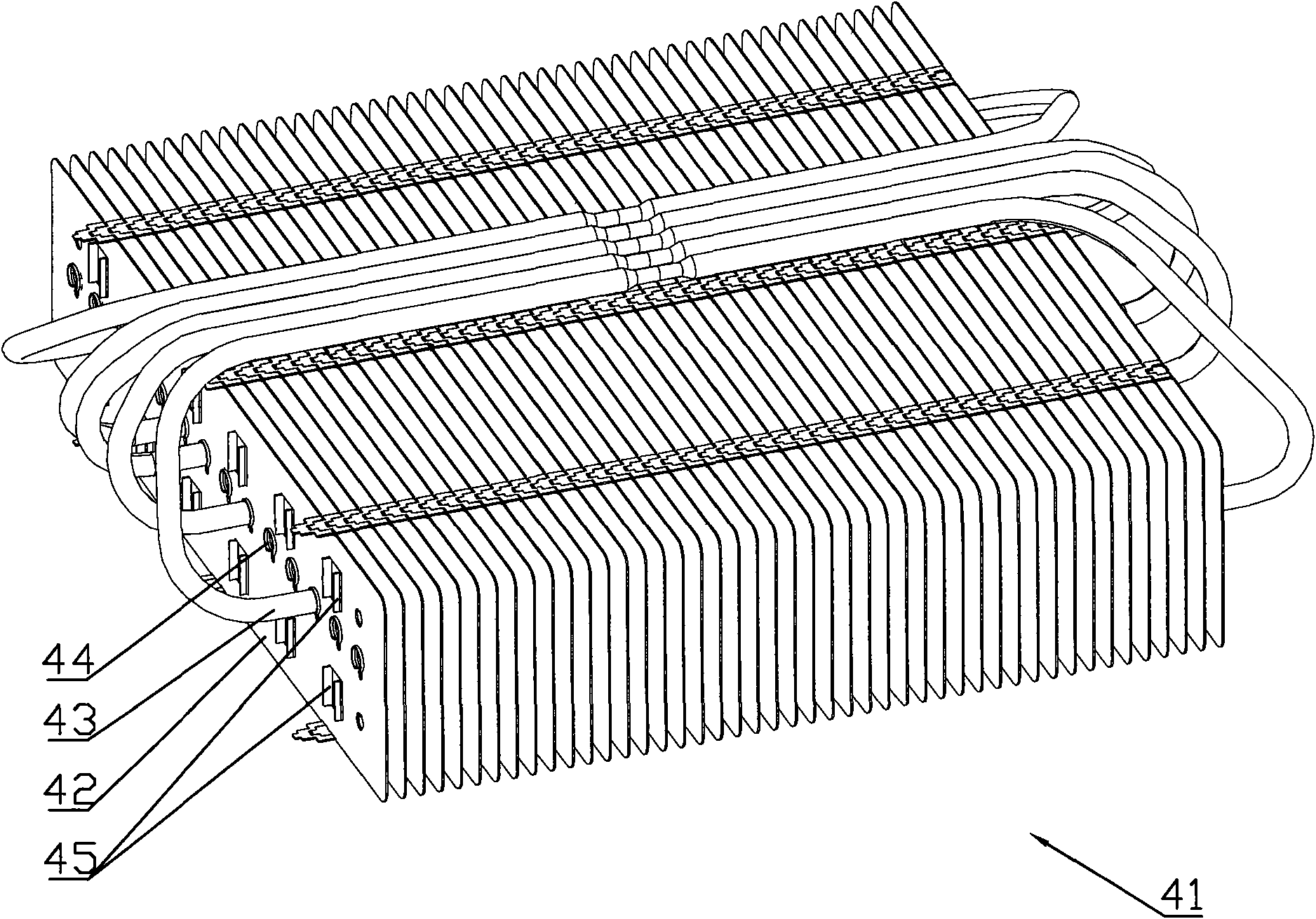

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] like figure 1 , 2 Shown, the present invention comprises LED chip, chip base 46, the cooling device that links to each other with chip base 46 and the light distribution device that is located on the chip base 46; The heat pipe 43 of the chip base 46; the chip base 46 is correspondingly provided with a plurality of inner grooves 47 matched with the heat pipe 43 for accommodating the heat pipe 43, and the inner groove 47 can be semicircular, "V" Shaped, "U" shaped or polygonal groove, in this embodiment a semicircular inner groove 47 is used, so that the circular heat pipe 43 can be closely attached to the wall of the inner groove 47, and lead-free tin A layer of flux welds the two together. The chip is covered on the chip base 46 by thermally conductive silver paste.

[0028]The light distribution device comprises a light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com