Absorption cuvette and on-line monitoring titration method for ammonia nitrogen

An absorption dish and titration technology, applied in the field of analytical chemistry, can solve problems such as difficult cleaning, deviation of end point value, non-stop titration, etc., and achieve the effects of increasing volume, improving measurement accuracy, and preventing measurement failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 reproducibility test

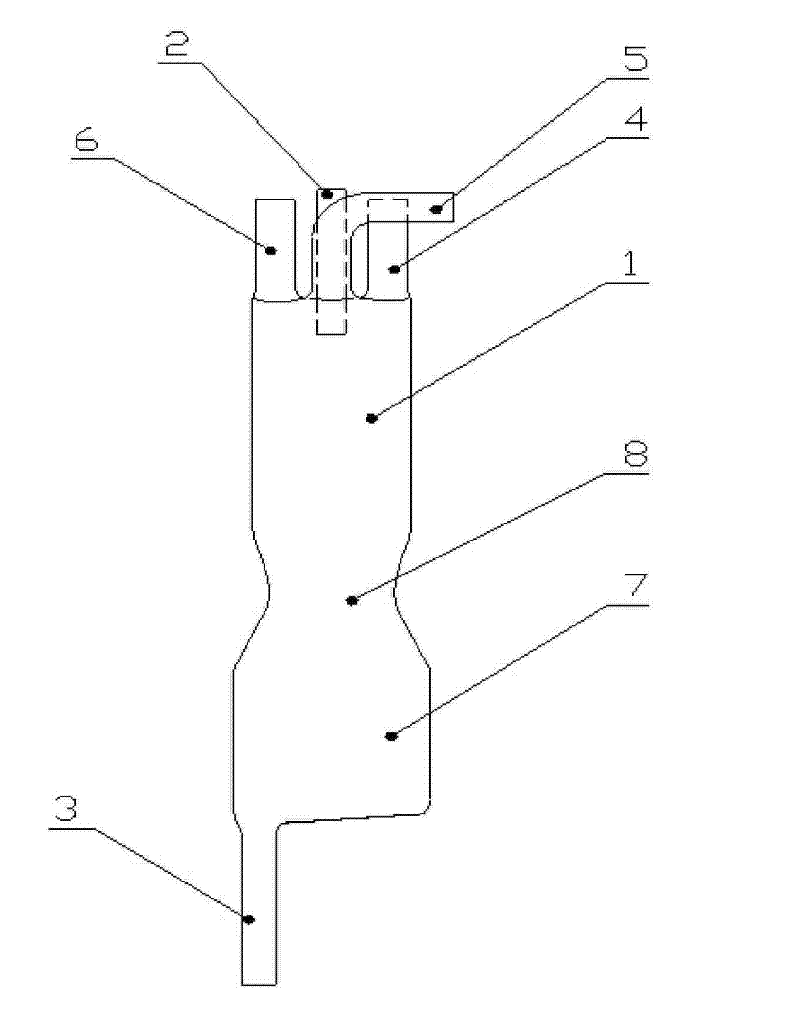

[0034] use image 3 For the absorption cuvette shown, the absorption solution (boric acid solution with a T value of 18%) is added into the absorption pool from the upper absorption solution inlet 6, and the transmittance of the absorption solution is read through program control and automatically stored in the system as a titration End point T0; add alkaline solution (0.5% sodium hydroxide solution) to the waste liquid to be tested and heat at 120°C to distill out gaseous NH 3 , reaction formula: NH 4 + +OH - =NH 3 +H 2 O, gas NH 3 The gas is blown upward from the gas inlet 3 at the bottom of the absorption cuvette to be absorbed by the absorption liquid, and the reaction formula is: NH 3 +H + =NH 4 + .

[0035] After the distillation, the system reads the transmittance T1 of the reacted liquid in the absorption cell again, and compares it with the titration end point T0. If T1>T0, the titration starts. During the titratio...

Embodiment 2

[0052] Embodiment 2 tests actual waste water sample

[0053] test environment:

[0054] Ambient temperature: 25±5℃.

[0055] Humidity: 65% relative humidity.

[0056] Atmospheric pressure is 98KPa.

[0057] Power supply voltage (220±20)VAC.

[0058] Power frequency (50±0.5)Hz.

[0059] Reagent:

[0060] Absorbing solution: boric acid solution with a T value of 18%.

[0061] Distilling agent: 0.5% sodium hydroxide solution.

[0062] Titrant: 0.01mol / liter sulfuric acid solution.

[0063] use image 3 For the absorption cuvette shown, the absorption solution (boric acid solution with a T value of 18%) is added into the absorption pool from the upper absorption solution inlet 6, and the transmittance of the absorption solution is read through program control and automatically stored in the system as a titration End point T0; add alkaline solution (0.5% sodium hydroxide solution) to the waste liquid to be tested and heat at 120°C to distill out gaseous NH 3 , reaction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com