Liquid crystal display panel and manufacturing method thereof

A technology of liquid crystal display panels and manufacturing methods, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of large non-display area, small signal attenuation, and large signal attenuation, and achieve small area and small attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

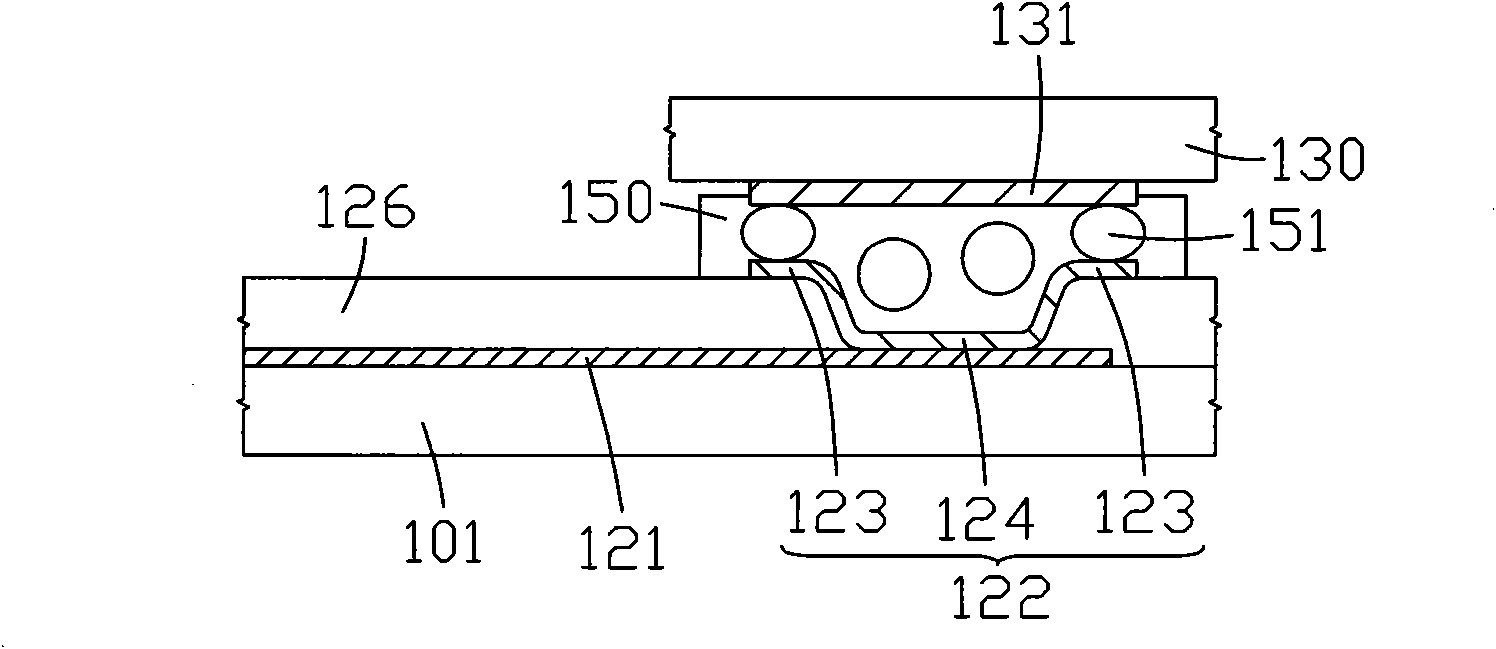

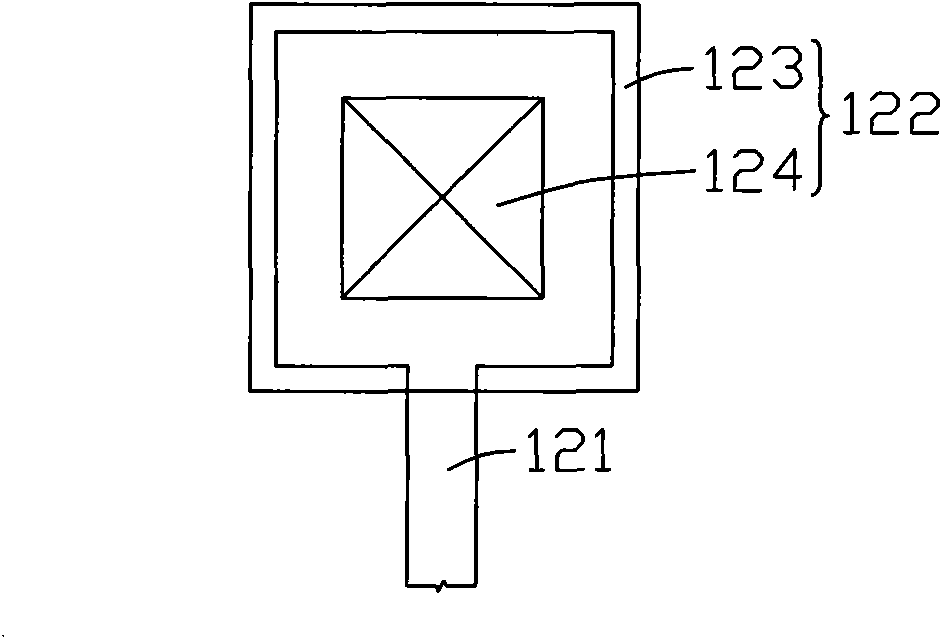

[0031] see Image 6 and Figure 7 , Image 6 is a schematic plan view of the first embodiment of the liquid crystal display panel of the present invention, Figure 7 Yes Image 6 The schematic cross-sectional view of the liquid crystal display panel along the VII-VII direction is shown. The liquid crystal display panel 30 includes a TFT substrate 301 and a color filter substrate 302 . The color filter substrate 302 is disposed opposite to the TFT substrate 301 and has an area smaller than that of the TFT substrate 301 . A portion of the TFT substrate 301 overlapping the color filter substrate 302 defines a display area 310 , and a portion of the TFT substrate 301 not overlapping the color filter substrate 320 defines a non-display area 320 . A liquid crystal layer 303 is disposed between the TFT substrate 301 and the color filter substrate 302 corresponding to the display area 310 .

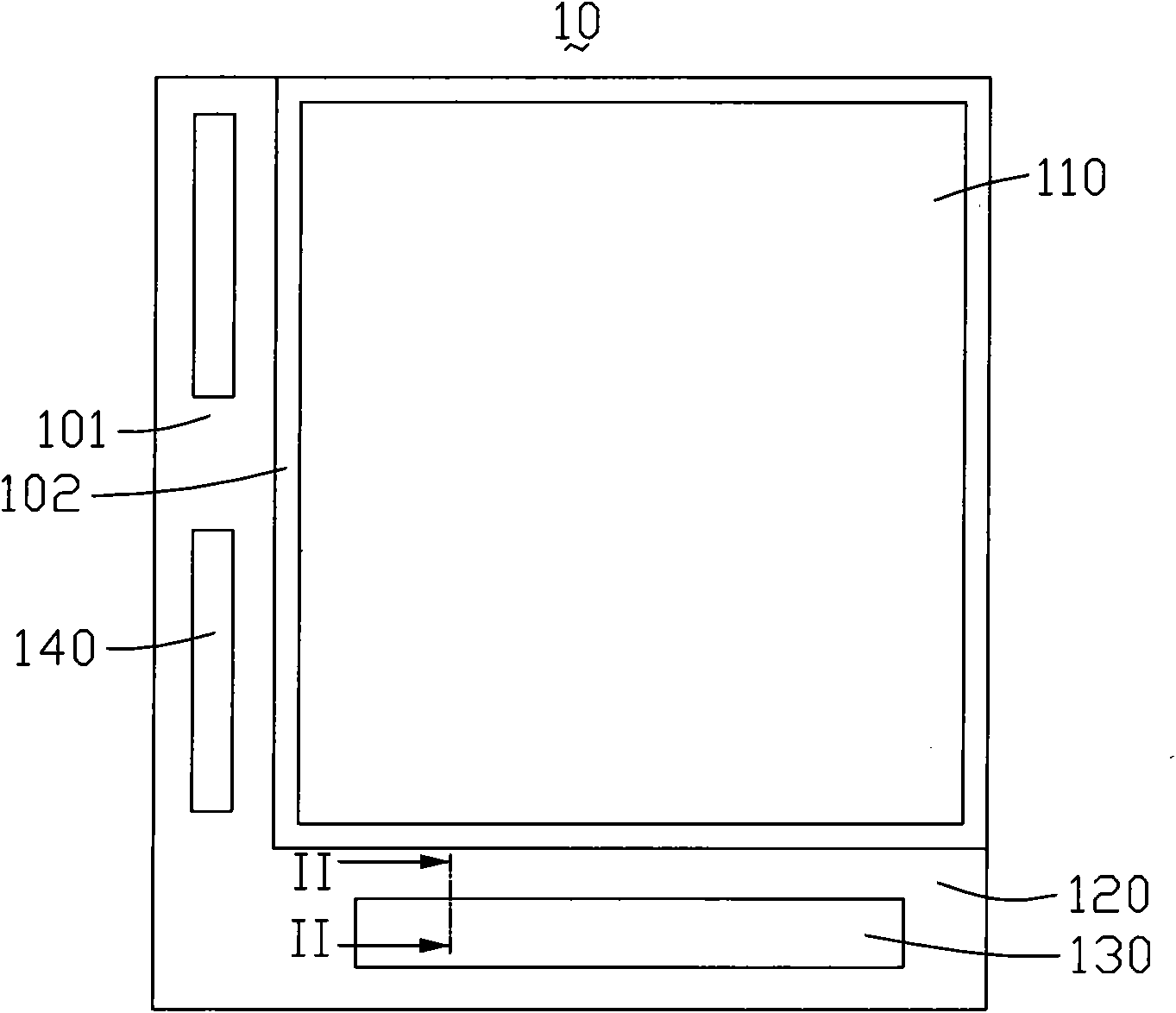

[0032] The non-display area 320 includes a scan driver 330, two data drivers 340, a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com