Automobile battery thermal management system and working method thereof

A technology of battery thermal management and working method, applied in the field of vehicle battery thermal management system, can solve the problems of power battery failure, hidden danger of vehicle operation safety, performance degradation, etc., and achieve the effect of prolonging service life, ensuring safety, and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

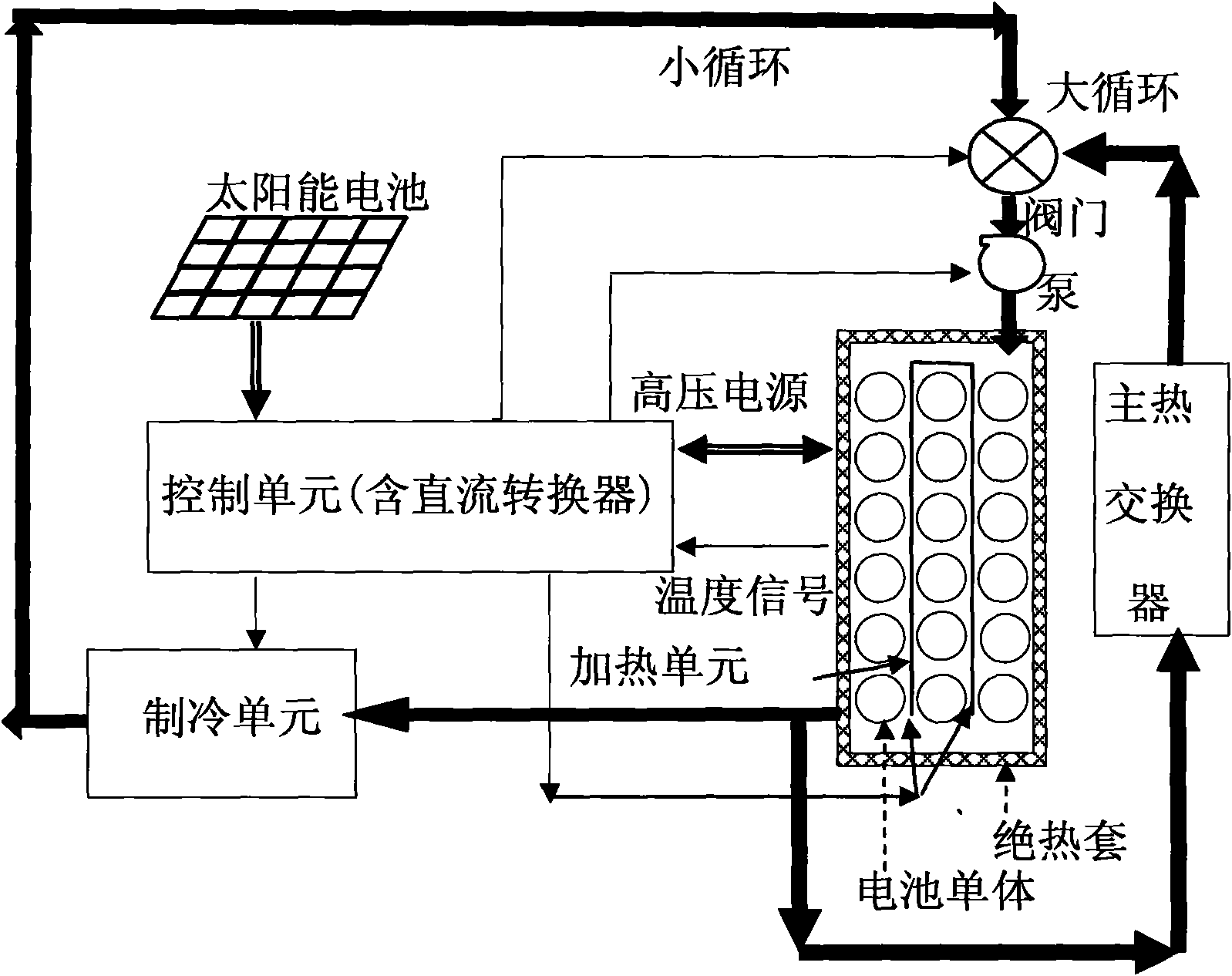

[0019] The structure of the vehicle battery thermal management system of the present invention is shown in the accompanying drawings, including:

[0020] A battery pack, the battery pack is provided with battery units electrically connected to each other, the battery unit is composed of one or a plurality of battery cells electrically connected to each other, the battery pack is sealed and packaged, and most of each battery unit or All are surrounded by voids filled with cooling liquid, and all voids filled with cooling liquid are connected to each other, the voids filled with cooling liquid are provided with temperature sensors, and the battery pack is provided with inlets of cooling liquid and an outlet, the battery pack is provided with a heating unit immersed in the cooling liquid;

[0021] The inlet and outlet of the cooling liquid are respectively connected to two pipelines to form two cycles, namely a large cycle and a small cycle. The large cycle is the inlet and outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com