Two-stage limited pulse width precision electrical discharge pulse power source

A pulsed power supply and electrical discharge machining technology, applied in electric machining equipment, metal machining equipment, circuits, etc., can solve the problems of narrow pulse width and small energy, and achieve the effect of stable frequency, small discharge energy, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

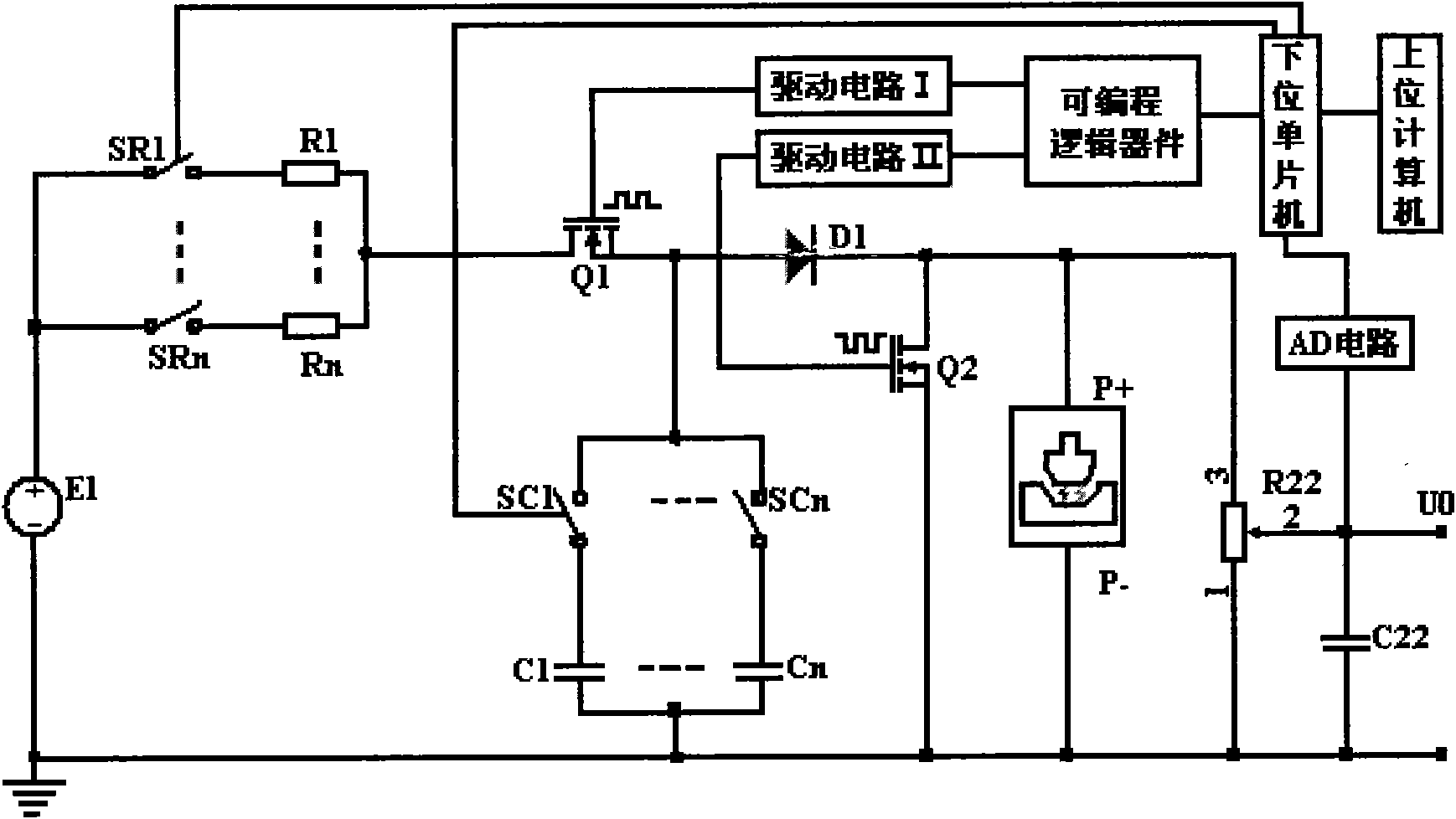

[0013] figure 1 Among them, the present invention is a two-stage pulse width-limited precision discharge machining pulse power supply, including a DC adjustable constant voltage source E1, resistor array selection switches SR1~SRn, capacitor array selection switches SC1~SCn, and high-power parallel resistor array R1 ~Rn, parallel processing capacitor array C1~Cn, measuring resistor R22, measuring capacitor C22, pre-stage FET Q1, post-stage FET Q2, diode D1, discharge electrode positive P+, discharge electrode negative P-, drive circuit I , Drive circuit II, programmable logic devices, lower microcontrollers, upper computers, AD circuits, etc. The DC adjustable constant voltage source E1 is electrically connected to the high-power resistors R1-Rn through the resistor array selection switches SR1~SRn, and then passes through the front-stage field effect transistor Q1, diode D1, discharge electrode positive P+, and discharge electrode negative P -, forming a pulse rising edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com