Lead fluoride crystal co-doped with ytterbium and alkaline and preparation method thereof

A lead fluoride and crystal technology, applied in the field of ytterbium-alkali co-doped lead fluoride crystal and its preparation, can solve the problems of low emission cross-section and low fluorescence lifetime at the laser wavelength position, and achieve improved emission cross-section and fluorescence lifetime, high absorption and the effect of the emission cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Growth of Yb by pulling method 0.03 :Na 0.03 :PbF 2 the crystal

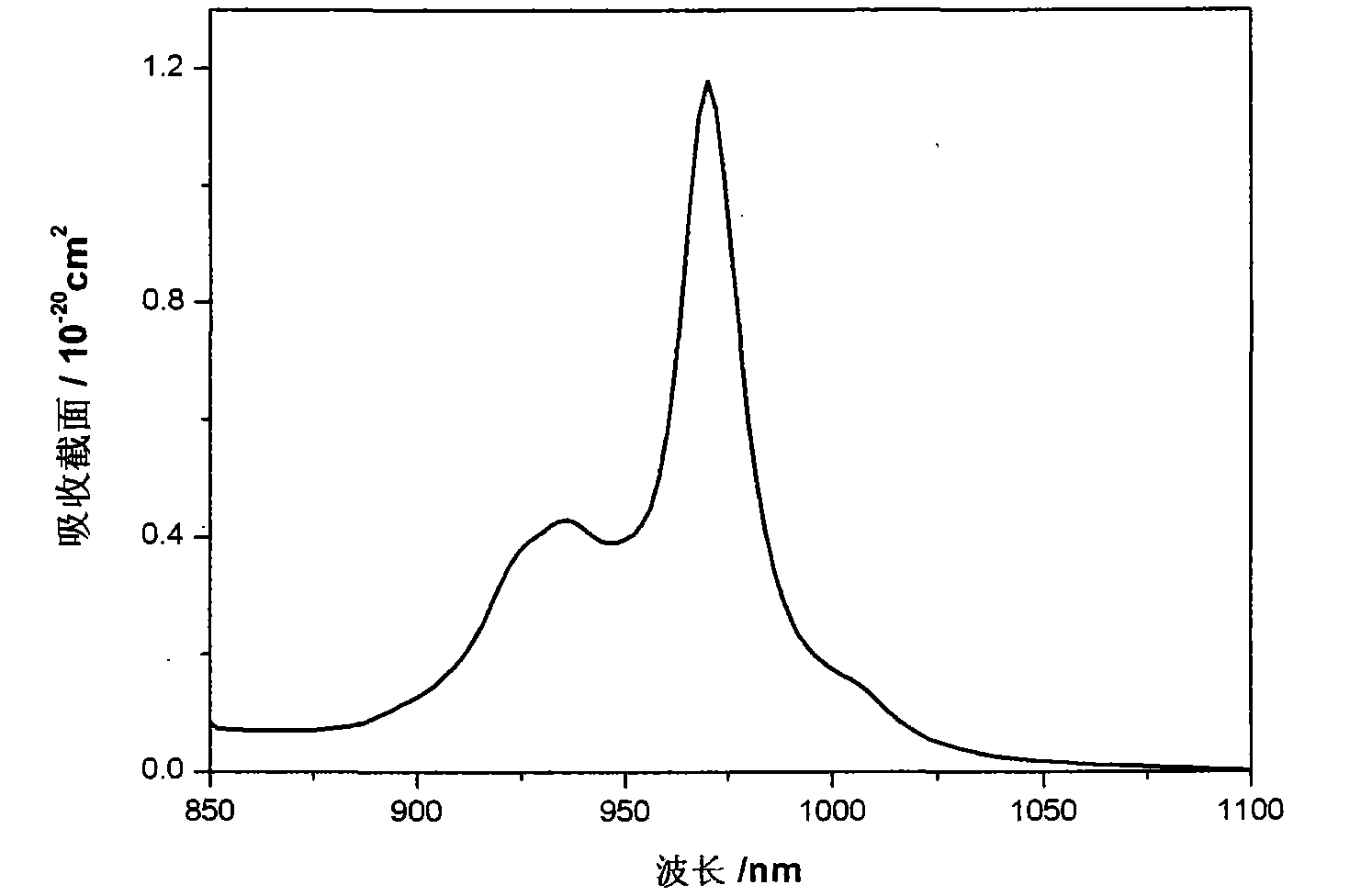

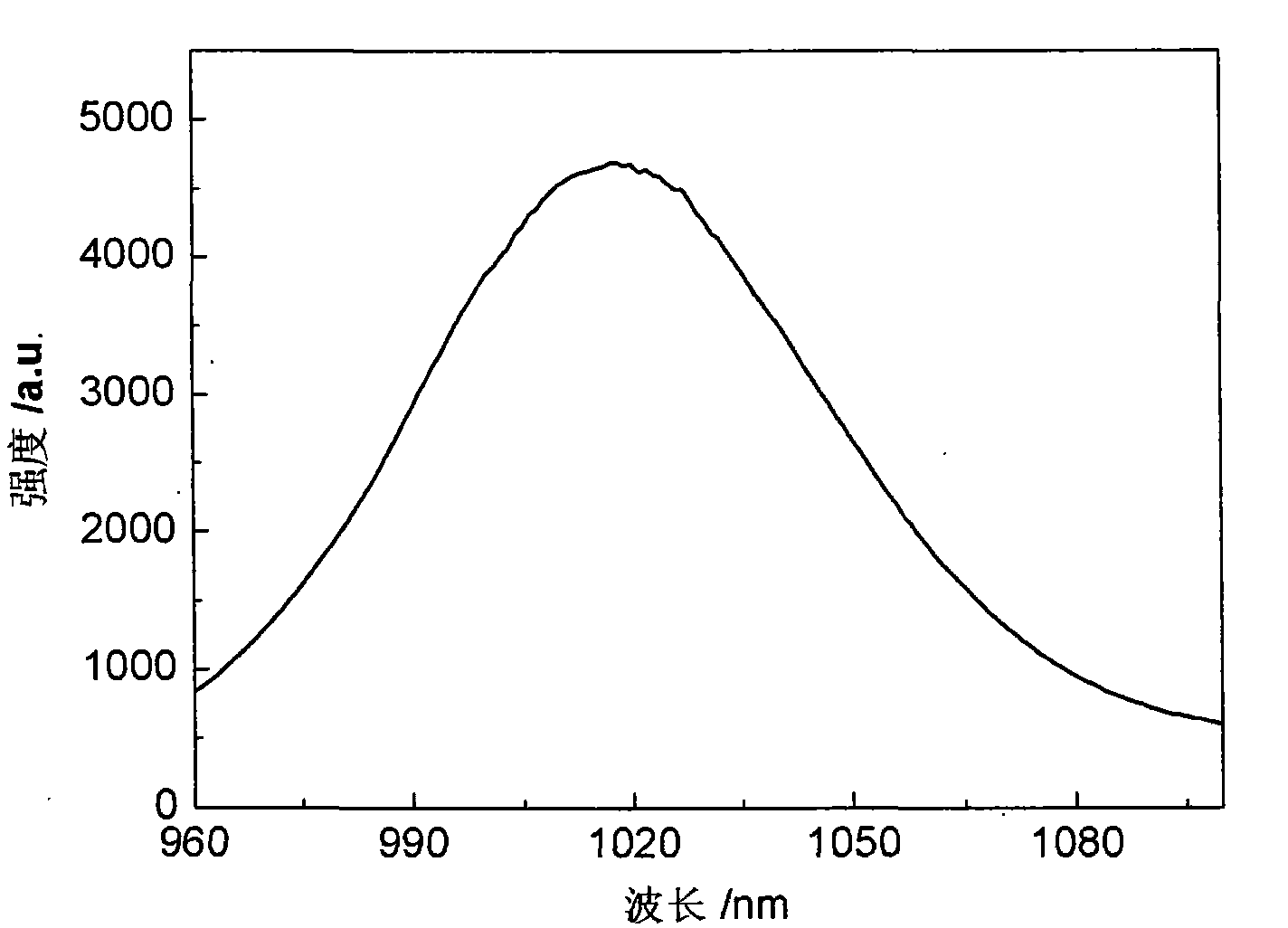

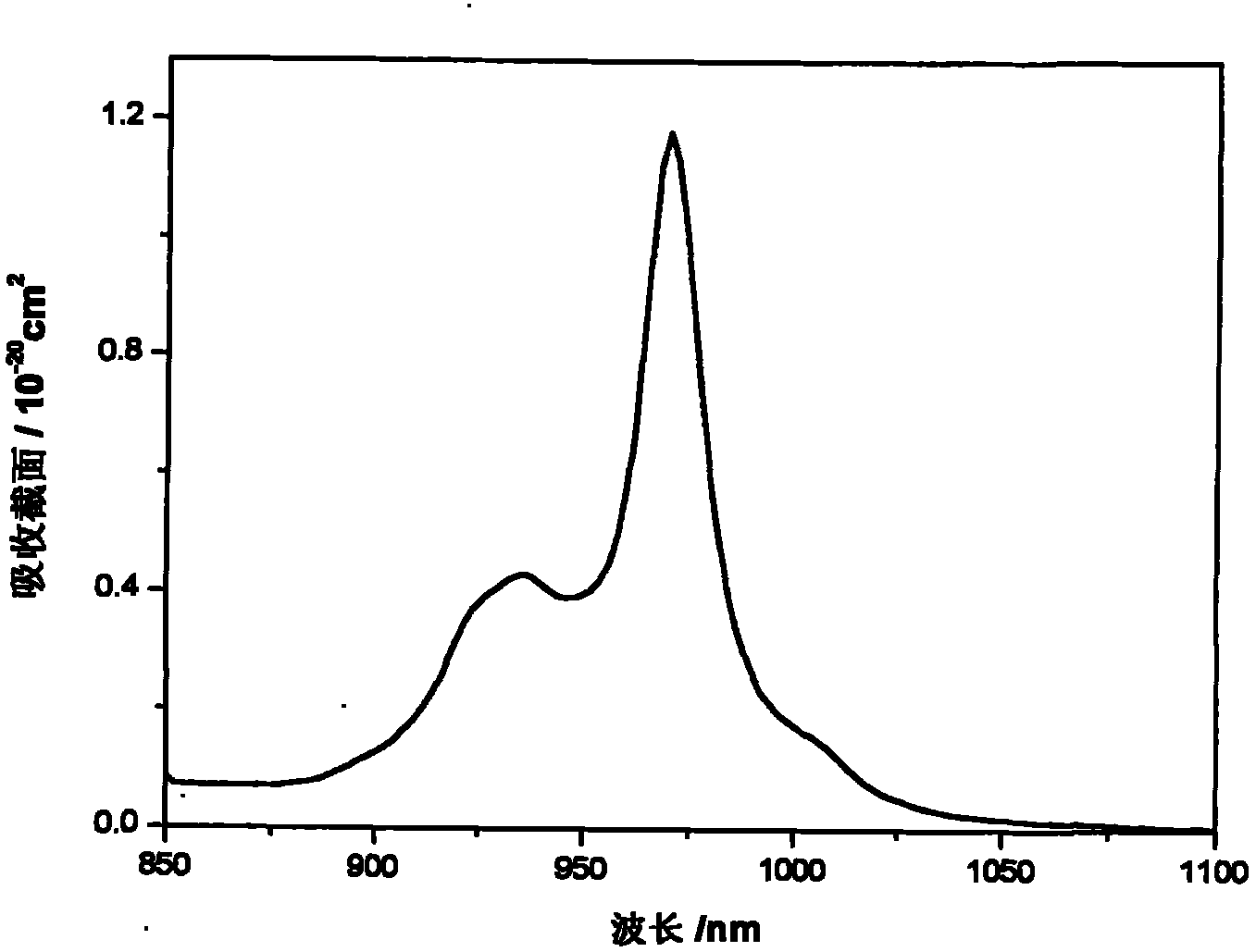

[0023] Press YbF 3 , NaF, PbF 2 The molar ratio is 0.03:0.03:1 for batching, fully mixed and evenly pressed into blocks, put into a graphite crucible, and use PbF 2 The crystal is used as the seed crystal, and the growth atmosphere is CF 4 Protective gas, the pulling speed is 2 mm / hour, and the rotation speed is 12 revolutions / minute. After the growth is completed, it is cooled to room temperature at a cooling rate of 50° C. / hour. After the crystal is taken out, it is processed into 10×10×1mm 3 The sample is subjected to spectral test, and its absorption spectrum is as follows figure 1 As shown, the fluorescence spectrum as figure 2 shown. Now the test result of embodiment 1 is listed in table 1 and with Yb:YAG, Yb:CaF 2 performance comparison.

[0024] The present invention adopts alkali metal ion M (being Na + 、K + , Li + ) to balance Yb 3+ Ions replace Pb 2+ The resulting sy...

Embodiment 2

[0027] Embodiment 2: Growth of Yb by temperature gradient method 0.05 :K 0.05 :PbF 2 the crystal

[0028] Press YbF 3 , KF, PbF 2 The molar ratio is 0.05:0.05:1 for batching, fully mixed and evenly pressed into blocks, put into a graphite crucible, and place PbF at the bottom of the crucible 2 The crystal is used as the seed crystal, and the growth atmosphere is CF 4 Protective gas, cover the top of the crucible, raise the temperature at 50°C / hour to 820°C for 10 hours, then grow crystals at a cooling rate of 4°C / hour, and cool to room temperature at a cooling rate of 20°C / hour after growth.

Embodiment 3

[0029] Embodiment 3: growing Yb by crucible descending method 0.1 : Li 0.2 :PbF 2 the crystal

[0030] Press YbF 3 , LiF, PbF 2 The molar ratio is 0.1:0.2:1 for batching, fully mixed and evenly pressed into a block, put into a platinum crucible, and place PbF at the bottom of the crucible 2 The crystal is used as the seed crystal, and the growth atmosphere is CF 4 Protective gas, cover the top of the crucible. The crystal growth temperature gradient is set at 40°C / cm, the crucible is lowered at a speed of 3mm / hour, and cooled to room temperature at a cooling rate of 40°C / hour after the growth is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com