Biologically-aided totally-chlorine-free bleaching technology of flax cloth or fiber

A linen fabric, completely chlorine-free technology, applied in the textile industry, can solve problems such as cellulose degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

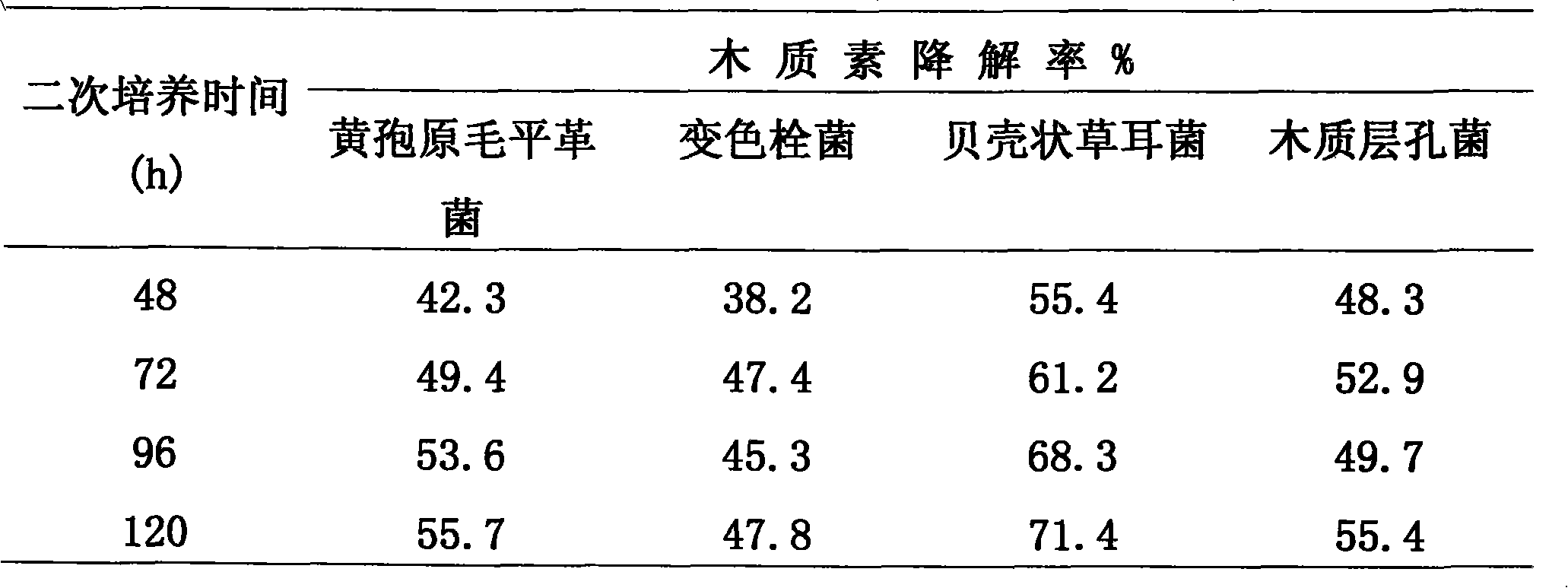

Examples

Embodiment 1

[0026] The biologically assisted linen fabric or fiber is fully chlorine-free bleaching process. The original linen fabric is scouring and pickling with alkali, and then bleached with hydrogen peroxide after biological pretreatment. The hydrogen peroxide rebleaching process is carried out according to the following conditions: hydrogen peroxide 4-15g / L, PH value 7-11, bleaching temperature 40-80℃, bath ratio 1:5-20, bleaching time 0.5-2 hours, the whiteness of the bleached product can reach more than 80%, and the tensile strength can reach 500-900× 800-1200N, the wool effect is greater than 8cm, which meets the current technical requirements for linen fabric bleaching.

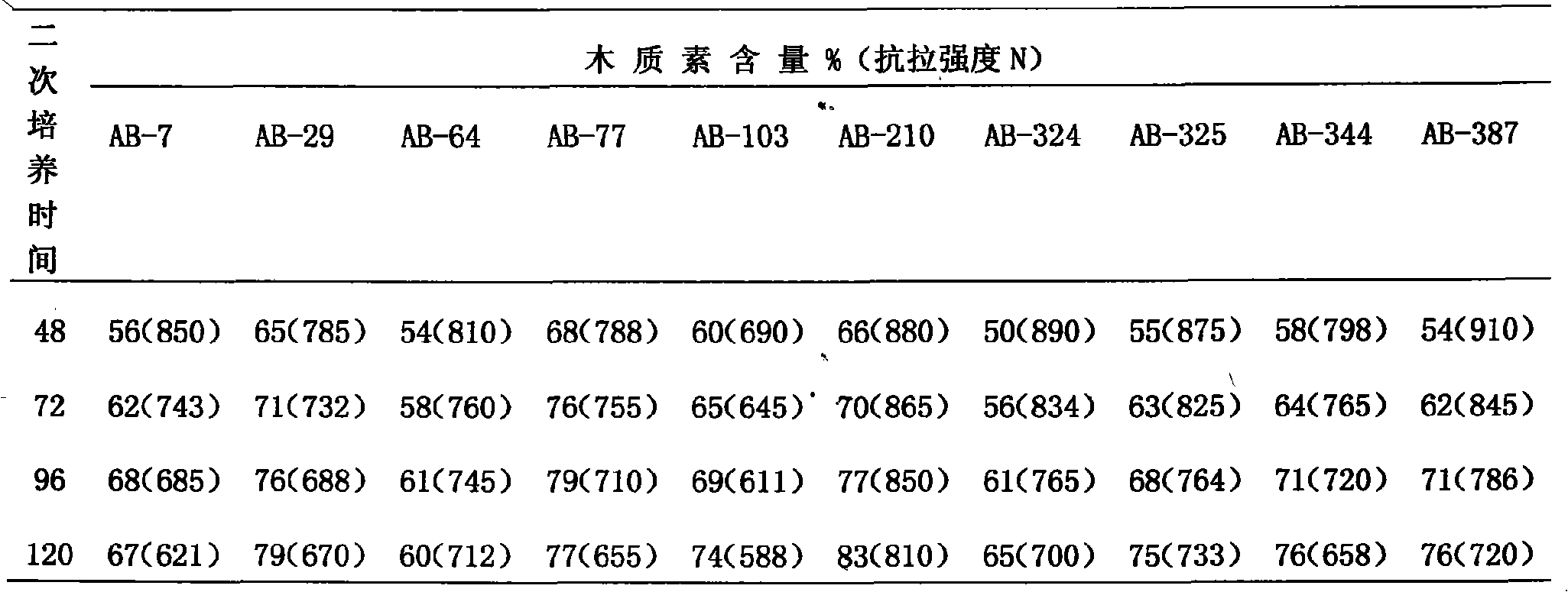

Embodiment 2

[0028]In the biologically assisted flax fabric or fiber full chlorine-free bleaching process, the bacterial strains used in the biological pretreatment process are: Panus conchatus through ultraviolet irradiation and NTG cellulose-deficient mutant strain AB-210 , the biological pretreatment process uses the secondary culture solution of bacterial species, and the biological pretreatment process time is 2-8 hours by immersing the flax fabric in the culture solution of 10-50 times the weight of the biological pretreatment process. During the process, a cellulase inhibitor was added, and the dosage was 2-20g / L.

Embodiment 3

[0030] In the biologically assisted flax fabric or fiber full chlorine-free bleaching process, the bacterial strains used in the biological pretreatment process are: Panus conchatus through ultraviolet irradiation and NTG cellulose-deficient mutant strain AB-210 , the biological pretreatment process uses the secondary culture solution of bacterial species, and the flax fabric is immersed in the culture solution of 10-50 times the weight, preferably 1:20-30, and the biological pretreatment process time is 3 -5 hours, cellulase inhibitor was added in the biological pretreatment process, and the dosage was 8-12g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gross effect | aaaaa | aaaaa |

| Gross effect | aaaaa | aaaaa |

| Gross effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com