Positive photoresist, insulation layer and organic light emitting diode

A technology of light emitting diode and positive photoresist, applied in the field of organic light emitting diode components, can solve the problems of substrate residue, high voltage, pattern shedding, etc., and achieve the effects of improving contrast, low dielectric constant, and preventing light leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

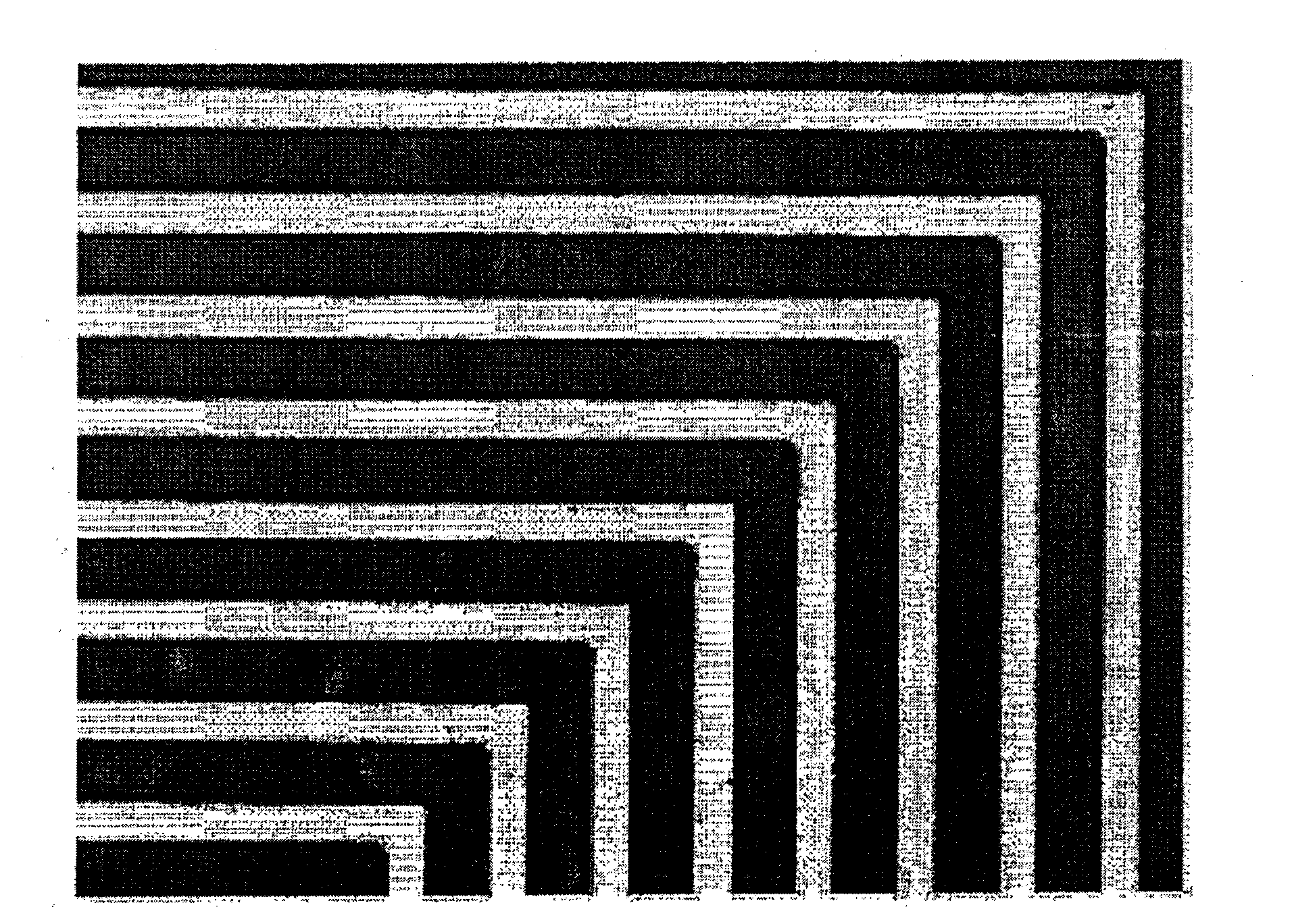

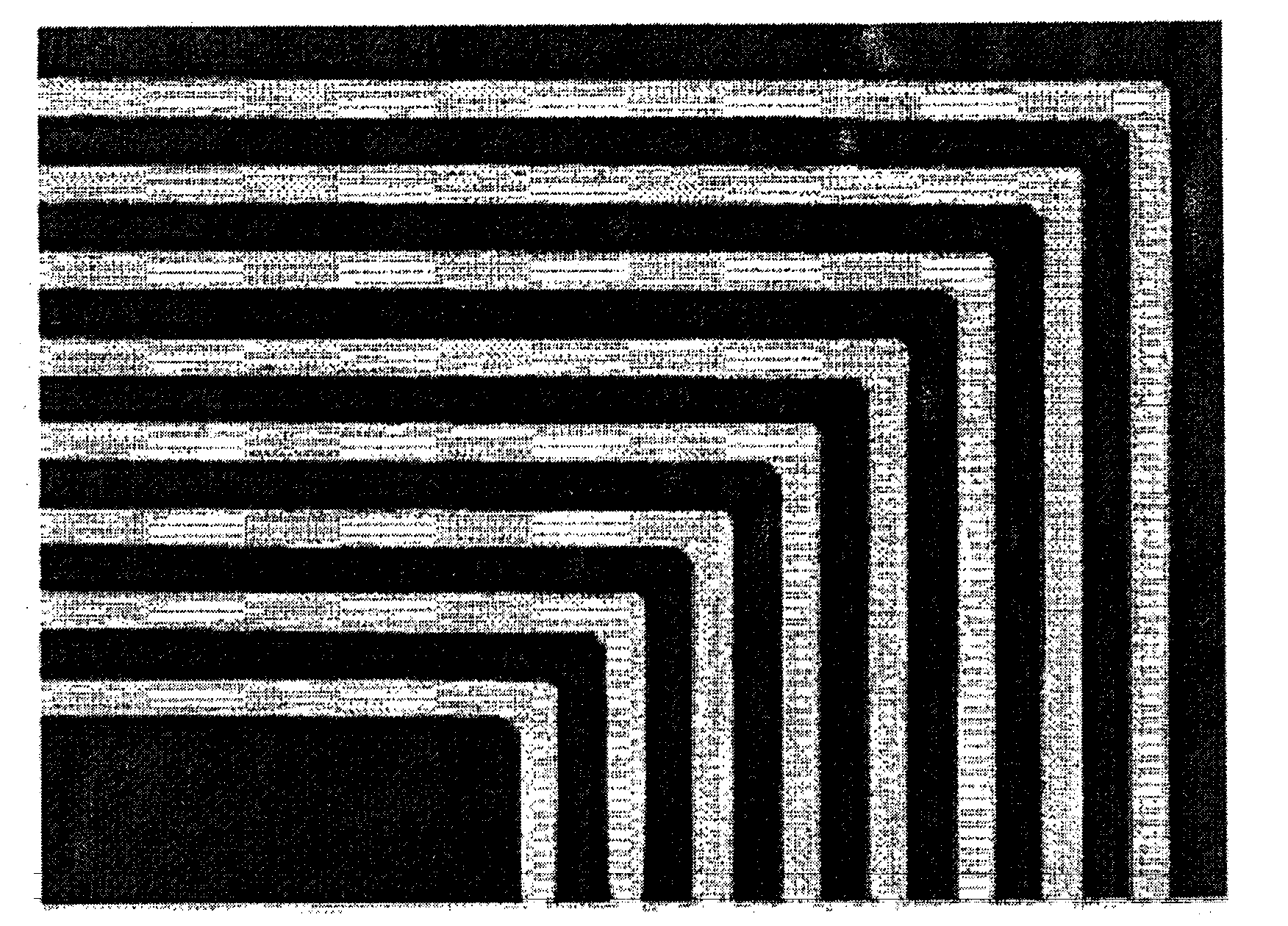

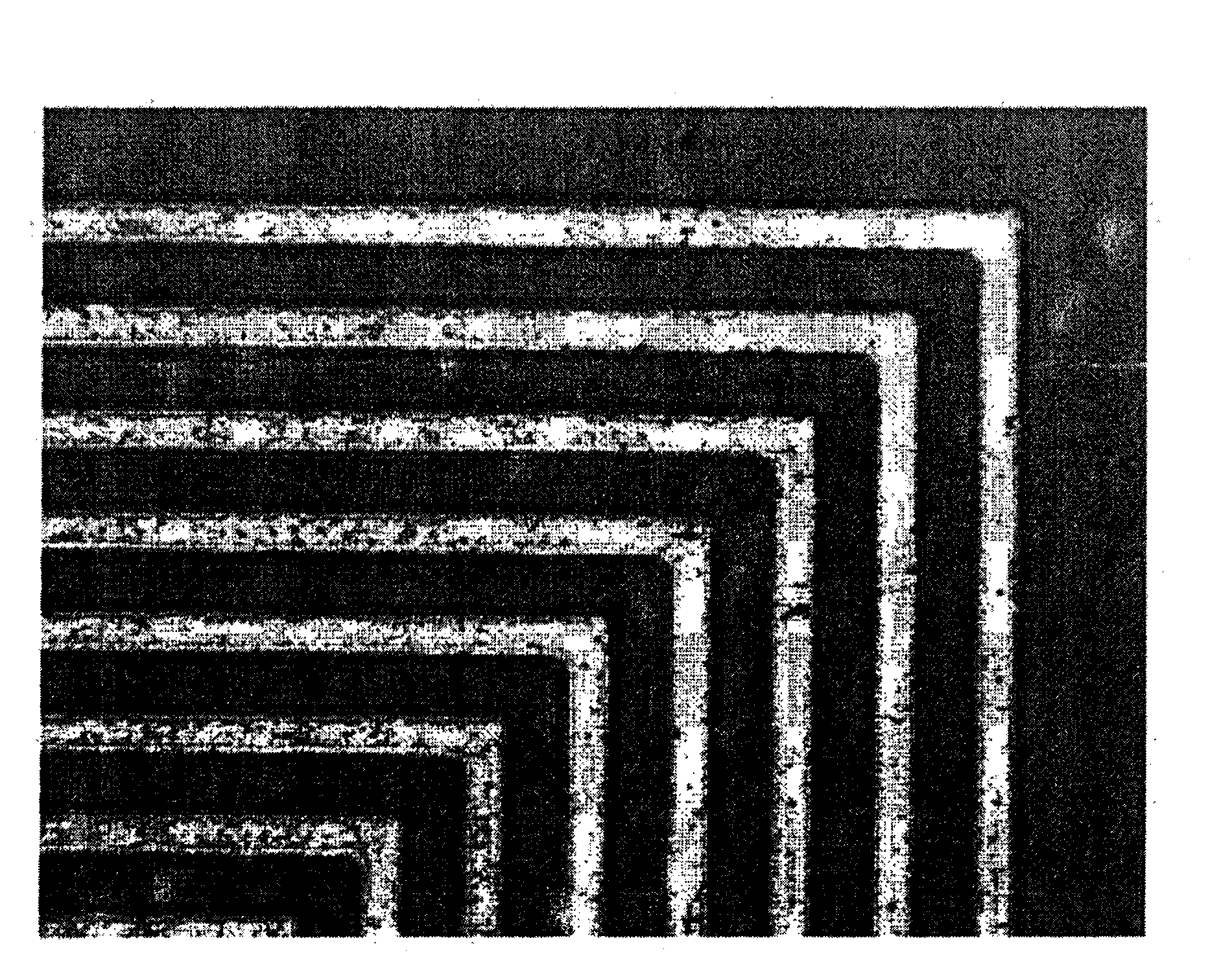

Image

Examples

Embodiment 1

[0086] In order to prepare black pigment paste using pigment mixing components, 10 parts by weight of red pigment particles (C.I.PIGMENT RED 254), 4 parts by weight of blue pigment particles (C.I.PIGMENTBLUE 15:3) were mixed with propylene glycol monoethyl ether acetate as solvent , 1 part by weight of yellow pigment particles (C.I.PIGMENT yellow 139), 4 parts by weight of pigment dispersant (polyester resin, with a weight average molecular weight of 25,000), 1 part by weight of binder resin (polyacrylate resin, with a weight average molecular weight of 10,000) into a mixer for blending. The size of the dispersed pigment is 100nm or less. Here, the solvent was used in an amount of 80 parts by weight.

[0087] In the above-mentioned black pigment paste, add 15 parts by weight of novolac resins (cresol novolac resin, m-cresol and p-cresol are 4: 6 by weight, and the weight average molecular weight is 8,000 cresol novolak resin and The cresol novolac resin with a weight average...

Embodiment 2

[0105] According to the same composition and method as in Example 1 above, a positive-type photoresist was prepared, except that propylene glycol monoethyl ether acetate was used as a solvent, and 10 parts by weight of red pigment particles (C.I.PIGMENT RED 254), 4 parts by weight 1 part by weight of blue pigment particles (C.I.PIGMENT BLUE 15:3), 1 part by weight of yellow pigment particles (C.I.PIGMENT yellow139), 4 parts by weight of pigment dispersant (polyacrylate resin, weight average molecular weight 20,000), 1 part by weight of adhesive An agent resin (polyacrylate resin, weight average molecular weight: 10,000) was placed in a mixer and blended. The size of the dispersed pigment is 100nm or less. Here, the solvent was used in an amount of 80 parts by weight.

[0106] In the same manner as in Example 1, an insulating layer was formed using the fabricated positive-type photoresist and analyzed.

[0107] The analysis results are shown in Table 1.

Embodiment 3

[0109] According to the same composition and method as in Example 1 above, a positive-type photoresist was prepared, except that propylene glycol monoethyl ether acetate was used as a solvent, and 10 parts by weight of red pigment particles (C.I.PIGMENT RED 254), 4 parts by weight 1 part by weight of blue pigment particles (C.I.PIGMENT BLUE 15:3), 1 part by weight of yellow pigment particles (C.I.PIGMENT yellow139), 4 parts by weight of pigment dispersant (polyester resin, weight average molecular weight 25,000), 1 part by weight of binder Resin (polyacrylate resin, weight average molecular weight: 7,500) was placed in a mixer and blended. The size of the dispersed pigment is 100nm or less. Here, the solvent was used in an amount of 80 parts by weight.

[0110] In the same manner as in Example 1, an insulating layer was formed using the fabricated positive-type photoresist and analyzed.

[0111] The analysis results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com