High-dynamic high-power bridge-type piezoceramics driving power with signal generator

A piezoelectric ceramic drive and signal generator technology, applied in the power supply field, can solve the problems of low closed-loop frequency response bandwidth, reduced load capacity, charge leakage, etc., to achieve the same bandwidth of output power, reduce power supply voltage, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

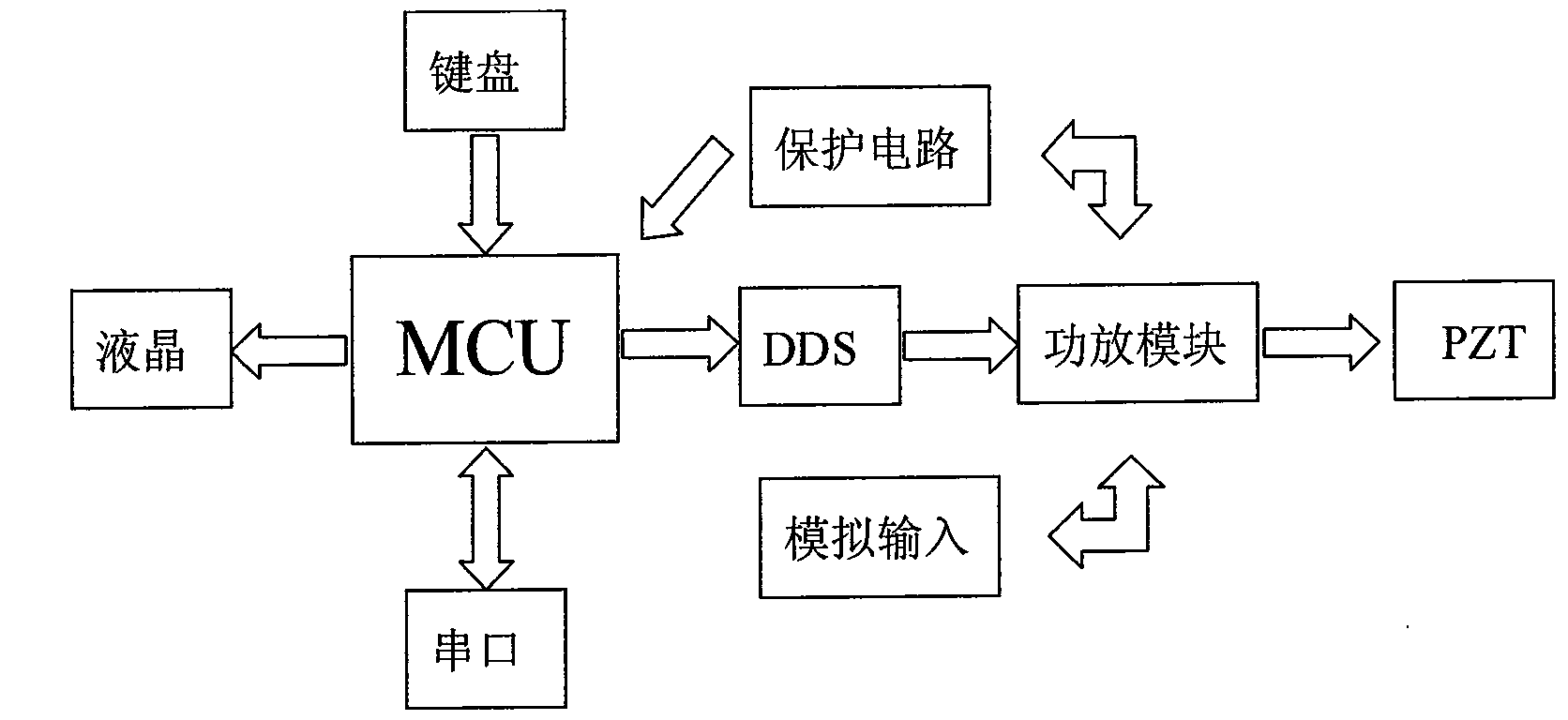

[0025] 1. The principle topology of the present invention is as follows: figure 1 Shown:

[0026] In this embodiment, a switching power supply is used to supply power to the entire system, and the output efficiency can reach more than 90%. The whole system is divided into 3 parts, the signal generation unit, the power amplifier module, the MCU unit is used in the middle to connect and realize the control functions such as keyboard liquid crystal, and the output of the power amplifier module drives the PZT actuator. This system also adopts functions such as voltage detection, current limit, and temperature protection to ensure the safety of the system during high power output.

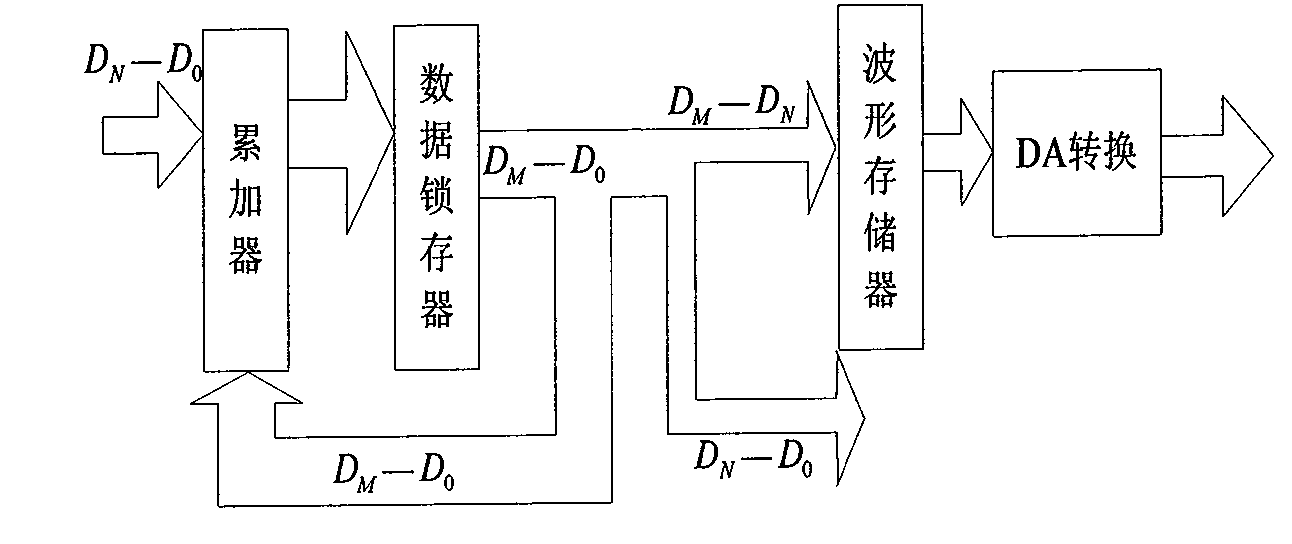

[0027] 2. DDS-based digital signal generator

[0028] Piezoelectric ceramic driving power needs to use various dynamic waveforms (sine, triangle, sawtooth, etc.) as input s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com