Cooling method for preventing microcracks on wheel steel continuous casting slabs

A cooling method and micro-crack technology, applied in the field of continuous casting technology, can solve the problems such as crack defects in the slab, unavoidable cracks, etc., and achieve the effect of eliminating crack defects and dense solidification structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

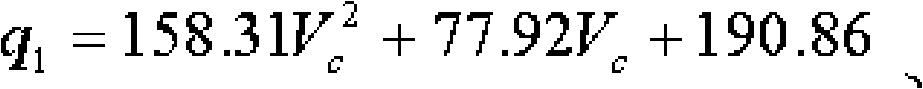

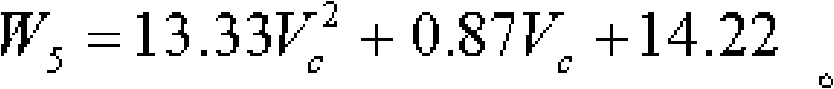

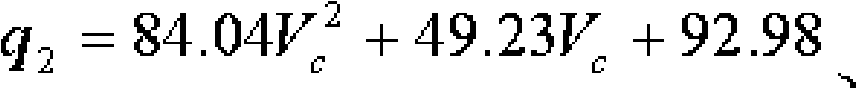

[0046] Continuous casting produces SAPH440 wheel steel slabs with a cross-sectional size of 200mm×1200mm, in which the solidified slab shell passes through the foot roll section, zero section, sector 1-2, sector 3-4, The secondary cooling is carried out in the 5-7 section of the fan shape. Among them, water spray cooling is used when the billet shell passes through the foot roll section and the zero section, and water spray cooling is used when the billet shell passes through the 1-2 section of the fan shape, the 3-4 section of the fan shape, and the 5-7 section of the fan shape. Aerosol spray cooling. The water volumes of the foot roll section, the zero section, sector 1-2, sector 3-4, and sector 5-7 are 153L / min, 393L / min, 84L / min, 70L / min and 84L / min respectively. The cooling intensity of the slab in the unit area direction of the sector above is 229L / (min·m 2 ), 116L / (min·m 2 ), 18L / (min·m 2 ), 15L / (min·m 2 ) and 11L / (min·m 2 ), and the surface temperatures of the sla...

Embodiment 2

[0049] Continuous casting produces SAPH440 wheel steel slabs with a cross-sectional size of 200mm×1050mm, in which the solidified slab shell passes through the foot roll section, zero section, sector 1-2, sector 3-4, The secondary cooling is carried out in the 5-7 section of the fan shape. Among them, water spray cooling is used when the billet shell passes through the foot roll section and the zero section, and water spray cooling is used when the billet shell passes through the 1-2 section of the fan shape, the 3-4 section of the fan shape, and the 5-7 section of the fan shape. Aerosol spray cooling. The water volumes of foot roll section, zero section, sector 1-2, sector 3-4 and sector 5-7 are 468L / min, 1280L / min, 351L / min, 176L / min and 263L / min respectively. The cooling intensity of the slab in the unit area direction of the sector above is 700L / (min·m 2 ), 377L / (min·m 2 ), 74L / (min·m 2 ), 38L / (min·m 2 ) and 36L / (min·m 2 ), and the surface temperatures of the slabs at...

Embodiment 3

[0052] Continuous casting produces SAPH440 wheel steel slabs with a cross-sectional size of 200mm×1150mm, in which the solidified slab shell passes through the foot roll section, zero section, sector 1-2, sector 3-4, The secondary cooling is carried out in the 5-7 section of the fan shape. Among them, water spray cooling is used when the billet shell passes through the foot roll section and the zero section, and water spray cooling is used when the billet shell passes through the 1-2 section of the fan shape, the 3-4 section of the fan shape, and the 5-7 section of the fan shape. Aerosol spray cooling. The water volumes of foot roll section, zero section, sector 1-2, sector 3-4 and sector 5-7 are 300L / min, 800L / min, 200L / min, 110L / min and 166L / min respectively. The cooling intensity of the slab in the unit area direction of the sector above is 449L / (min·m 2 ), 236L / (min·m 2 ), 42L / (min·m2 ), 24L / (min·m 2 ) and 22L / (min·m 2 ), and the surface temperatures of the slabs at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com