Laser processing control device and laser processing device

A technology for laser processing and control devices, applied in lasers, auxiliary devices, metal processing, etc., can solve the problems of laser penetration, abnormal hole diameter, inability to open holes, etc., and achieve the effect of accurate laser power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

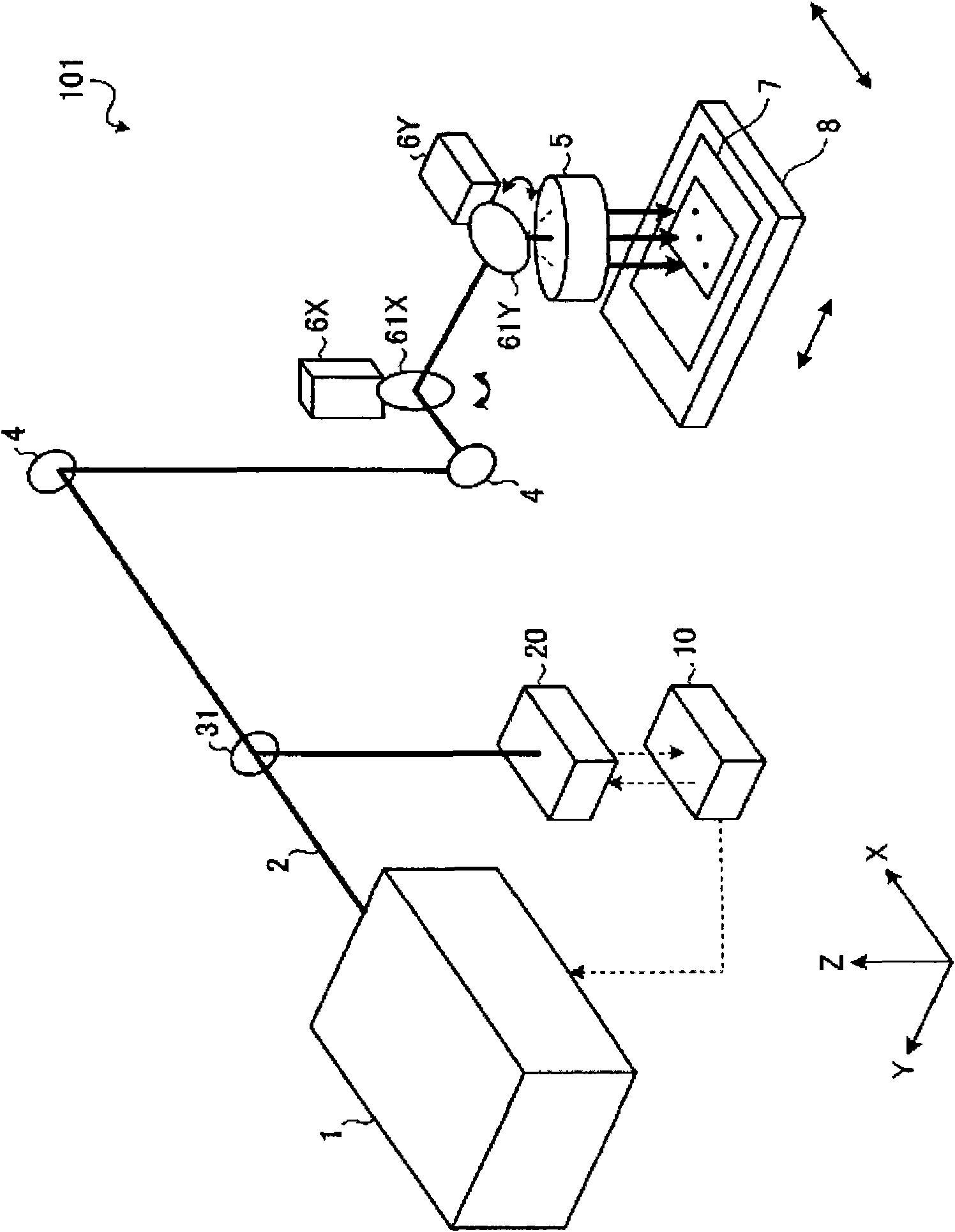

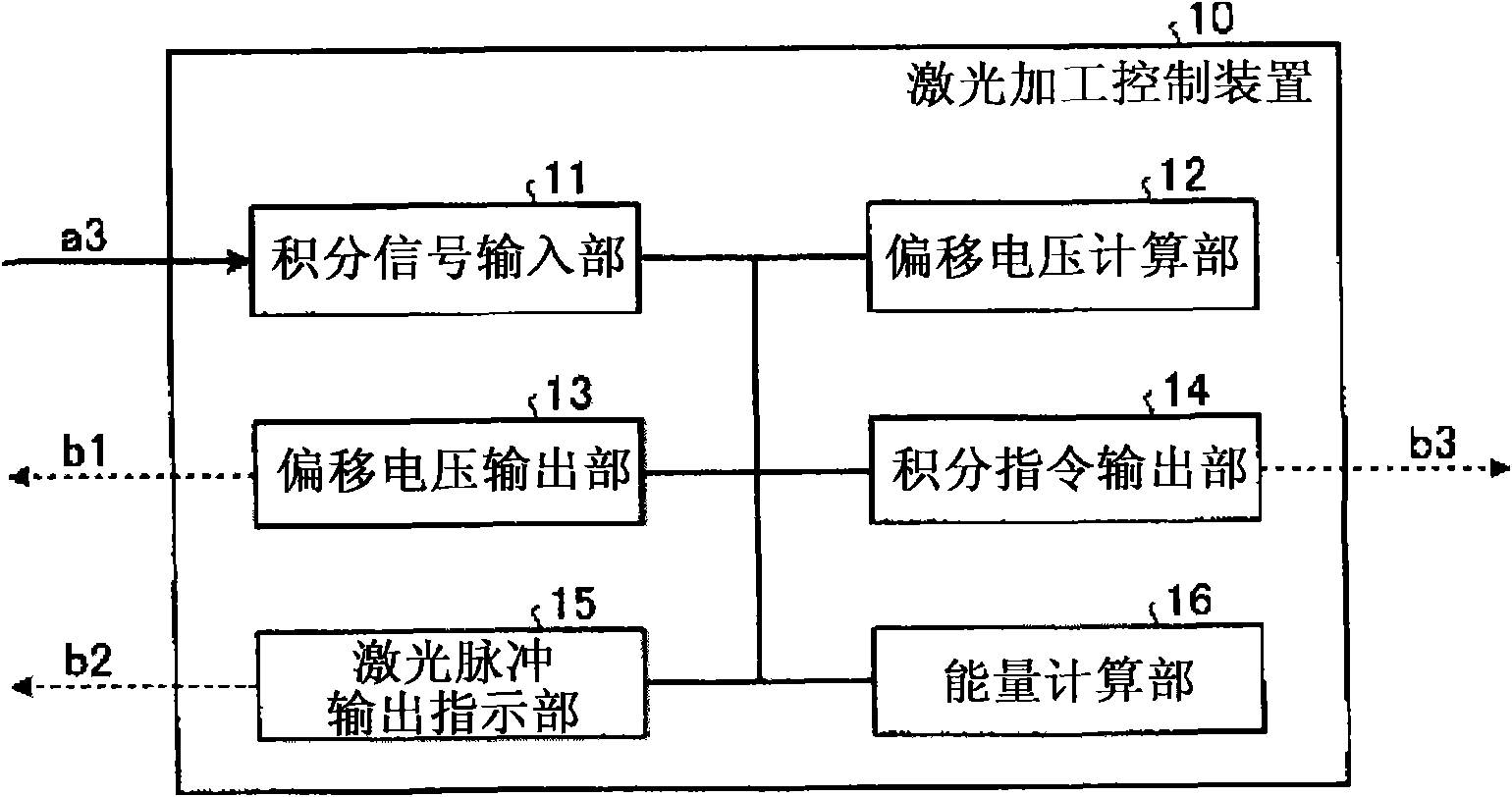

[0025] figure 1 It is a figure which shows the schematic structure of the laser processing apparatus concerning Embodiment 1 of this invention. The laser processing device 101 is a device that performs drilling processing or the like on the workpiece by irradiating pulsed laser light on the workpiece such as a printed board, and is controlled by the laser processing control device 10 .

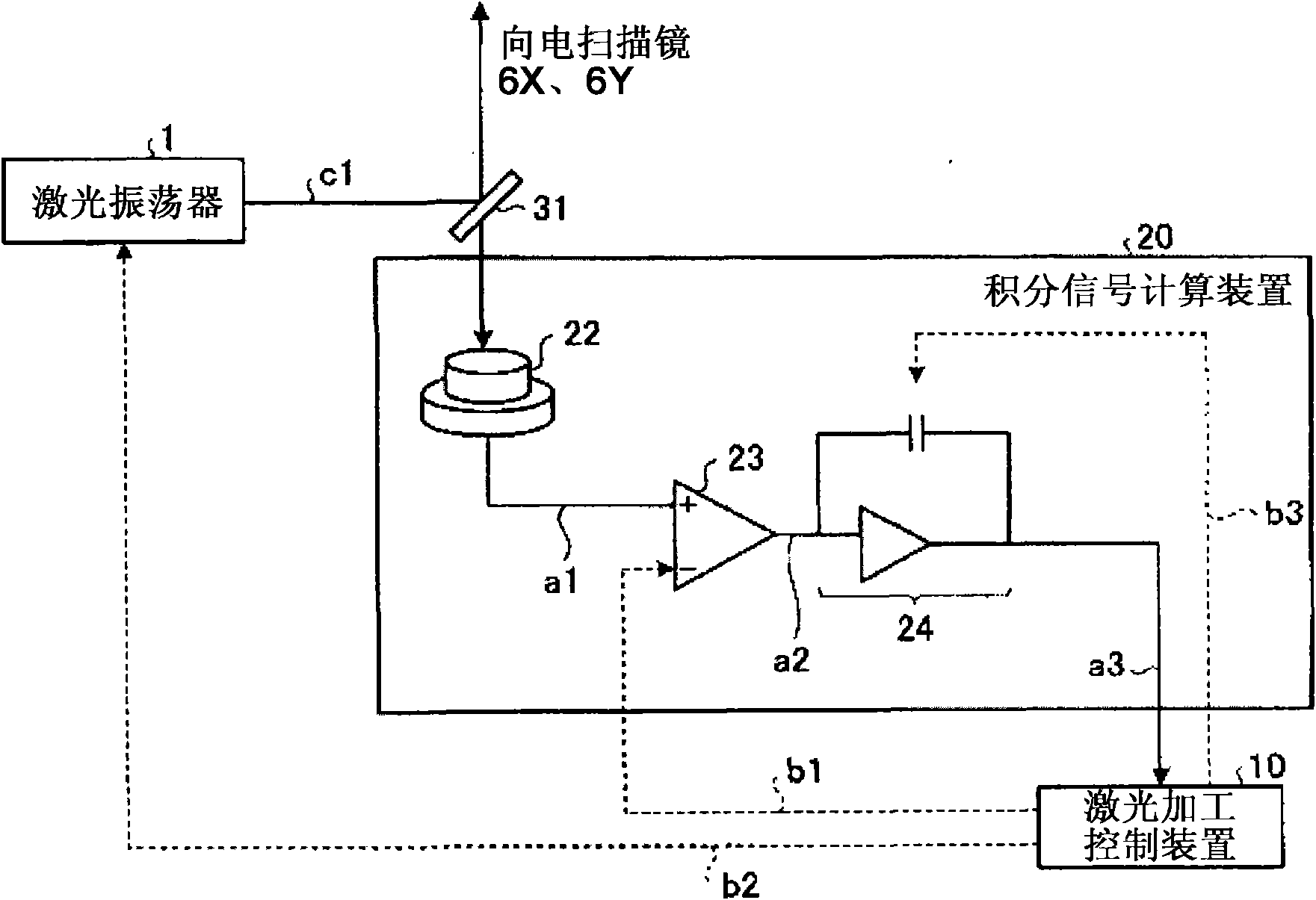

[0026] The laser processing device 101 has a laser oscillator 1, a reflection mirror 4, an fθ lens 5, a galvano scanner 6X, 6Y, a galvano scanner 61X, 61Y, an XY table 8, a partial reflection mirror (partial transmission mirror) 31, and An integral signal calculation device 20 , and a laser processing control device 10 . The laser oscillator 1 emits pulsed laser light (laser light 2 ) with a width of, for example, 1 to 100 μsec at an oscillation frequency of, for example, 100 to 10000 Hz, and enters the mirror 4 via the partial reflection mirror 31 . Part of the laser light 2 emitted from th...

Embodiment approach 2

[0071] Below, refer to Figure 10 ~ Figure 12 Embodiment 2 of the present invention will be described. In Embodiment 2, the laser processing control device 10 performs calculations using software, corrects the integrated signal a3 to a correct integrated signal (integrated signal in consideration of temperature drift), and uses the corrected integrated signal (integrated signal a4 described later). Calculate the actual energy of the pulsed laser.

[0072] Figure 10 It is a figure which shows the structure of the integrated signal measurement apparatus concerning Embodiment 2. exist Figure 10 Among the various constituent elements, for the implementation and figure 2 Components having the same functions as those of the integrated signal calculation device 20 in the first embodiment shown are denoted by the same reference numerals, and repeated explanations are omitted.

[0073] The integrated signal calculation device 20 is configured to include an infrared sensor 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com