Computer cycloidal jacquard knitter

A jacquard knitting machine and cycloid technology, applied in knitting fabrics, textiles and papermaking, electrical program control, etc., can solve the problems of low automation management efficiency, complex jacquard process, and high knitting failure rate, and achieve compact structure of the whole machine. Automated management benefits, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

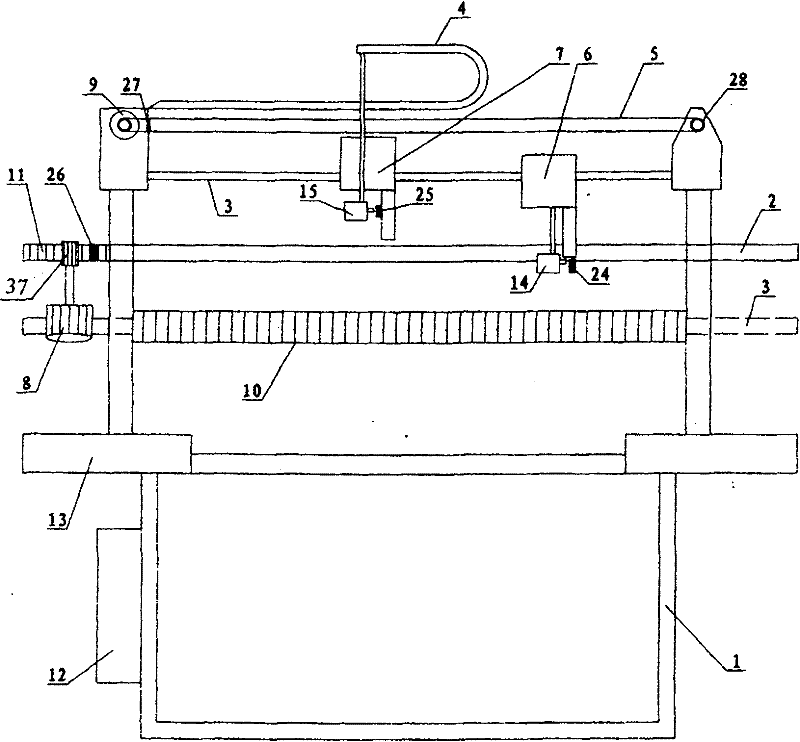

[0019] exist figure 1 Among them, one side of the frame 1 is provided with an outer box 12 for circuit boards, and the outer box 12 has built-in control system circuit boards. A keyboard 13 with a display is installed on the table of the frame 1, and all the parts are placed on the top of the frame 1 table. The characteristic components are stepping motors No. 1-No. 4. The stepping motors No. 1-4 are single-phase linear, and the AC power supply voltage is 110V or 220V. The rated current is 0.2A-1A, and the encoder is 400P / K. In order to save energy and reduce the failure rate, the power of the stepper motor is selected according to 1.2 times of the actual working current. The encoder circuit of the stepper motor is controlled by the unit controller. No. 1 stepper motor 14 drives the front braiding head 6, and is positioned at the front of the long ball guide rail 2 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com