Ethylene rectification tower sensitive plate temperature control system and control method thereof

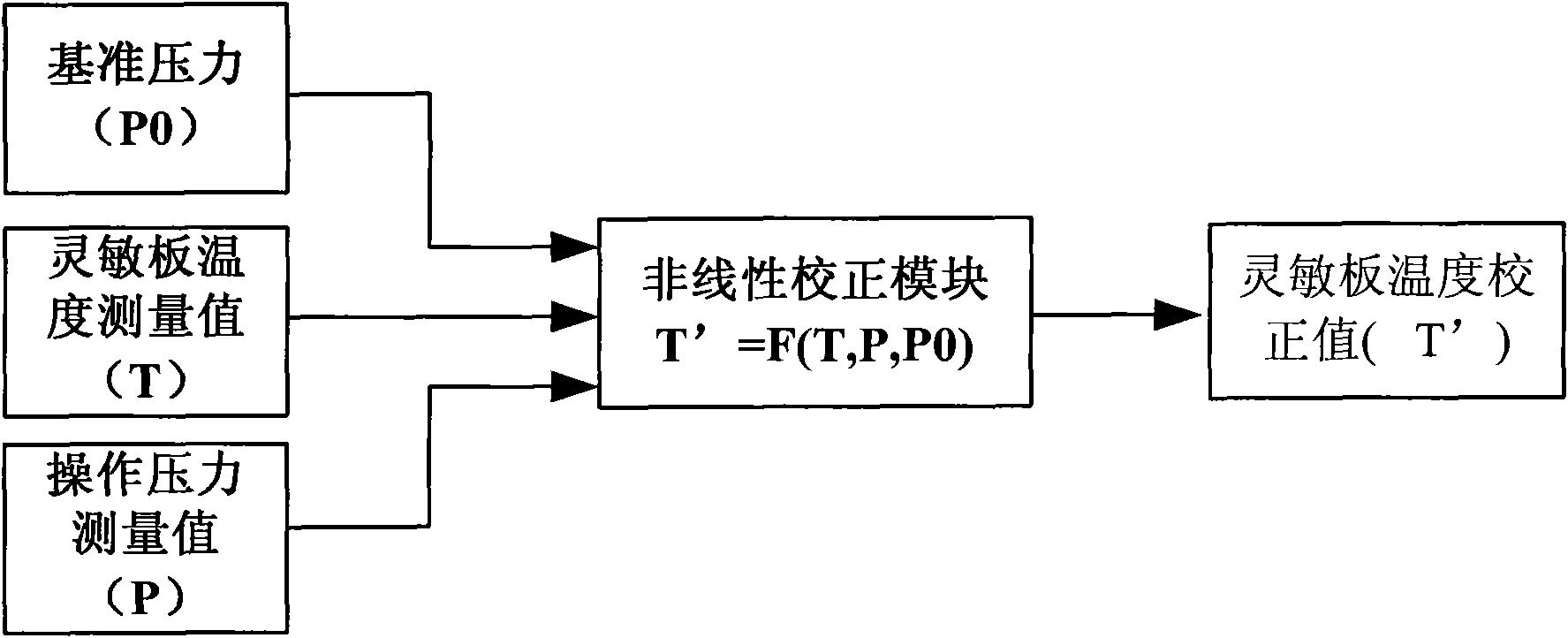

A technology of ethylene rectification tower and temperature controller, which is applied in the direction of distillation regulation/control, etc., can solve the problem of large temperature fluctuation of sensitive plate, large fluctuation of gas phase and liquid phase load, and inability to effectively control the heating capacity of the tower kettle reboiler, etc. problems, to achieve the effect of using raw materials and energy, and the load is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

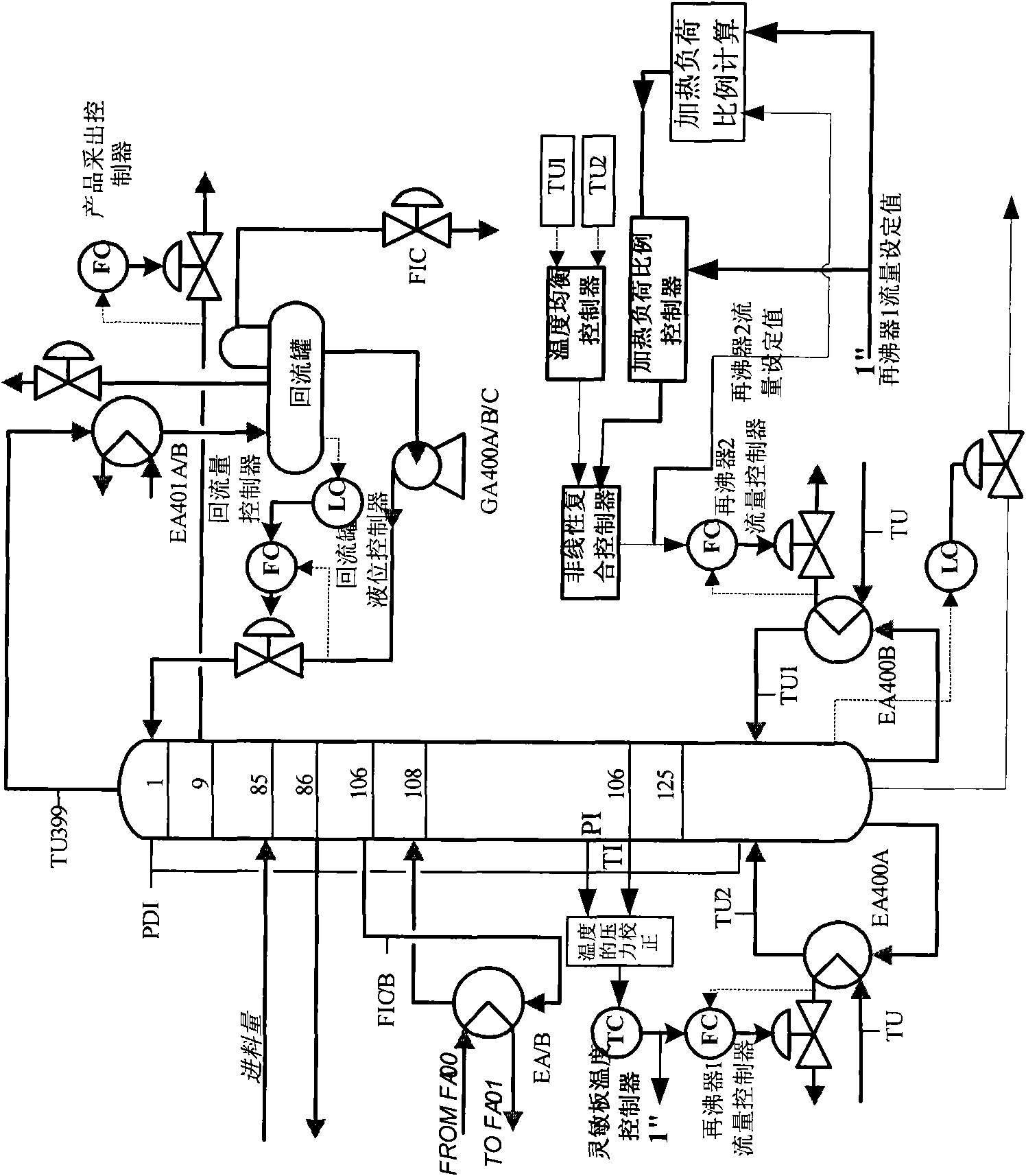

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

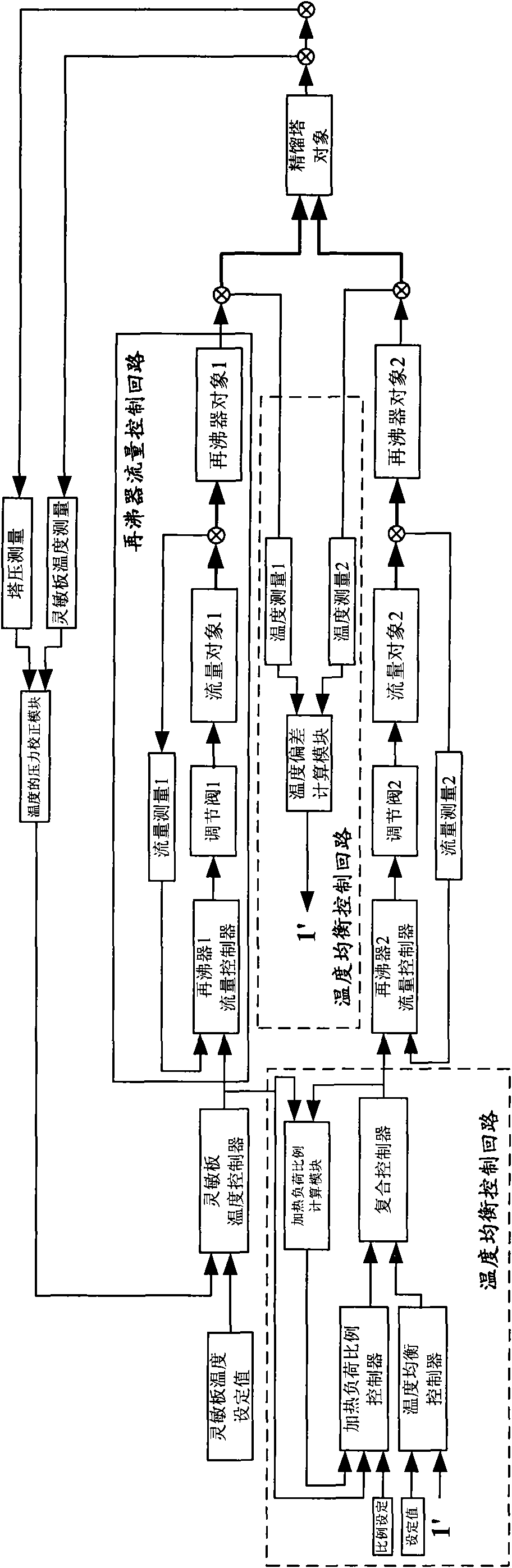

[0032] The sensitive plate temperature control system of the ethylene rectification column based on the DCS system of the present embodiment is as follows: figure 2As shown, including a sensitive plate temperature controller, reboiler 1 flow control loop, reboiler 2 flow control loop, a rectification column object, and the sensitive plate controller output connected to the two reboiler flow control loop inputs Two reboiler flow control loops are connected in parallel between the sensitive plate controller and the rectification tower object, the output ends of the two control loops are connected to the input end of the rectification tower object, and the rectification tower object is set by the flow rate input by the two control loops The values control the respective heating medium flow rates to provide heat sources for the reboiler of the rectificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com