Aluminum alloy and LED lamp substrate applying same

A technology of LED lamp base plate and aluminum alloy plate, which is applied in the field of aluminum alloy materials, can solve problems such as inconsistent screw tightening, difficulty in meeting heat dissipation requirements, and reduced heat conduction efficiency, so as to solve problems such as uneven thermal expansion coefficient, excellent high temperature oxidation resistance, Effect of improving LED life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

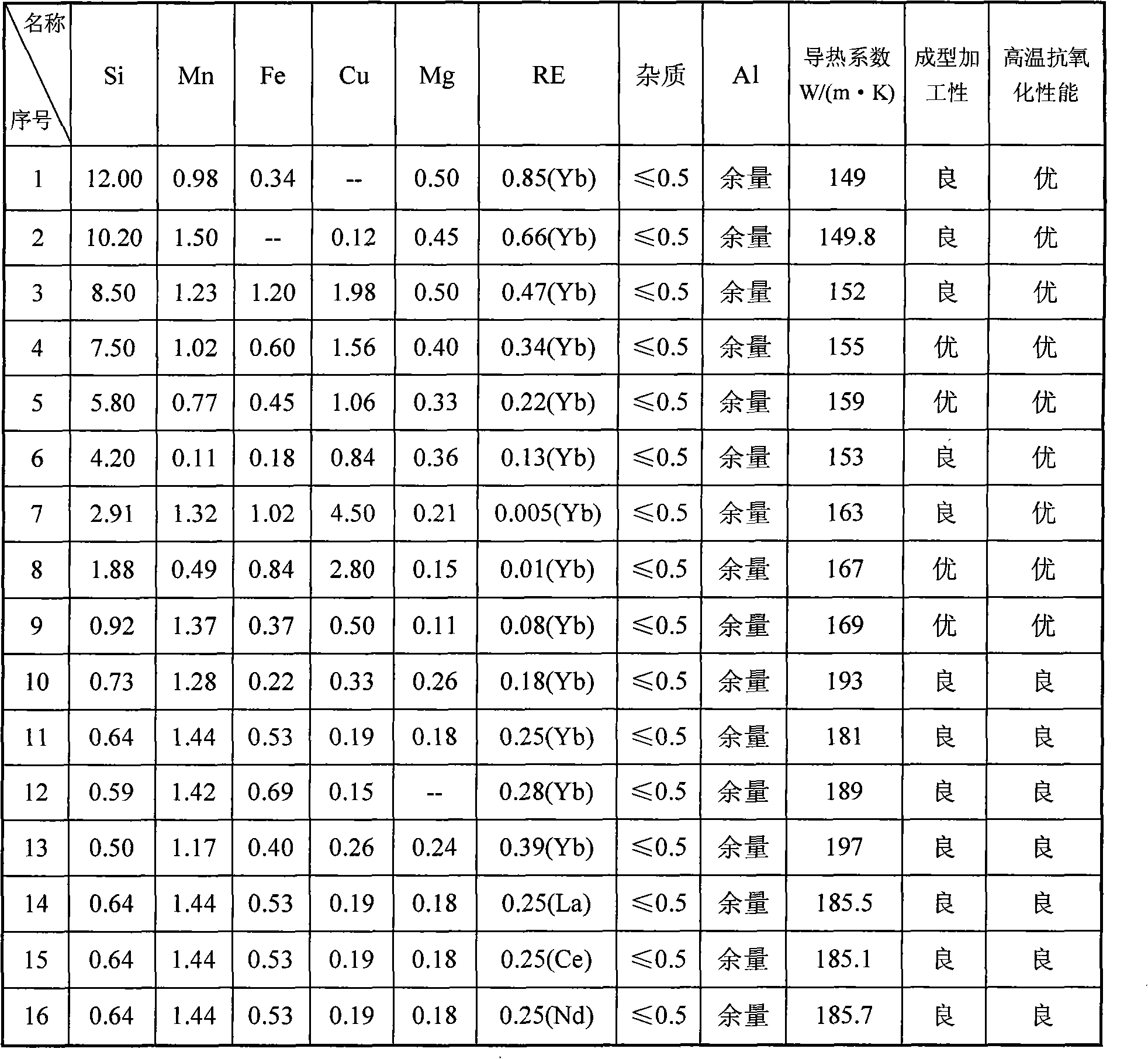

[0017] Below in conjunction with embodiment the present invention is described in further detail.

[0018] The concrete composition of aluminum alloy in the embodiment of the present invention is shown in Table 1, and its preparation process is:

[0019] First prepare a master alloy containing 20wt% rare earth (RE): melt pure aluminum at 740°C in a power frequency furnace, add RE, and finally make a master alloy containing 20wt% RE. Then, according to the conventional aluminum alloy preparation process (wherein, the aluminum alloy with a silicon content above 7.5wt% is prepared according to the high-silicon aluminum alloy preparation process), first melt pure aluminum at 740 ° C, under an inert gas atmosphere, according to the required amount, add Various alloy elements and the above-mentioned intermediate alloys are degassed and slag removed, and after standing still, the aluminum water is rolled into plates, and then quenched and aged. Of course, the aluminum alloy of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com