Back-fed millimeter wave broadband double ridged horn antenna

A ridge horn and millimeter-wave technology, applied in the field of microwave and millimeter-wave signal processing, can solve the problems of poor coaxial feeding performance, inconvenient connection, and inability to carry out accurate and effective design, and achieve the effect of good performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

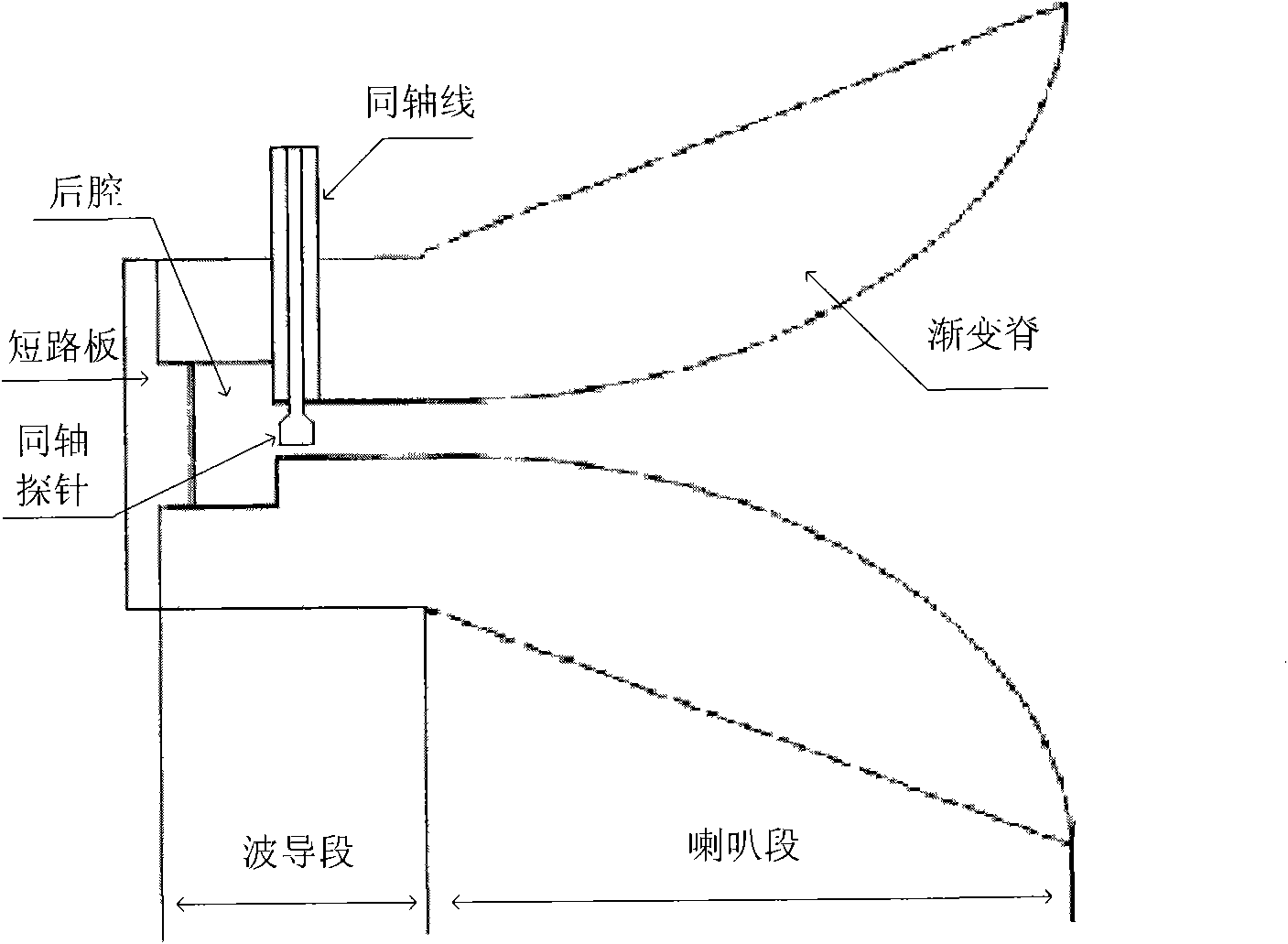

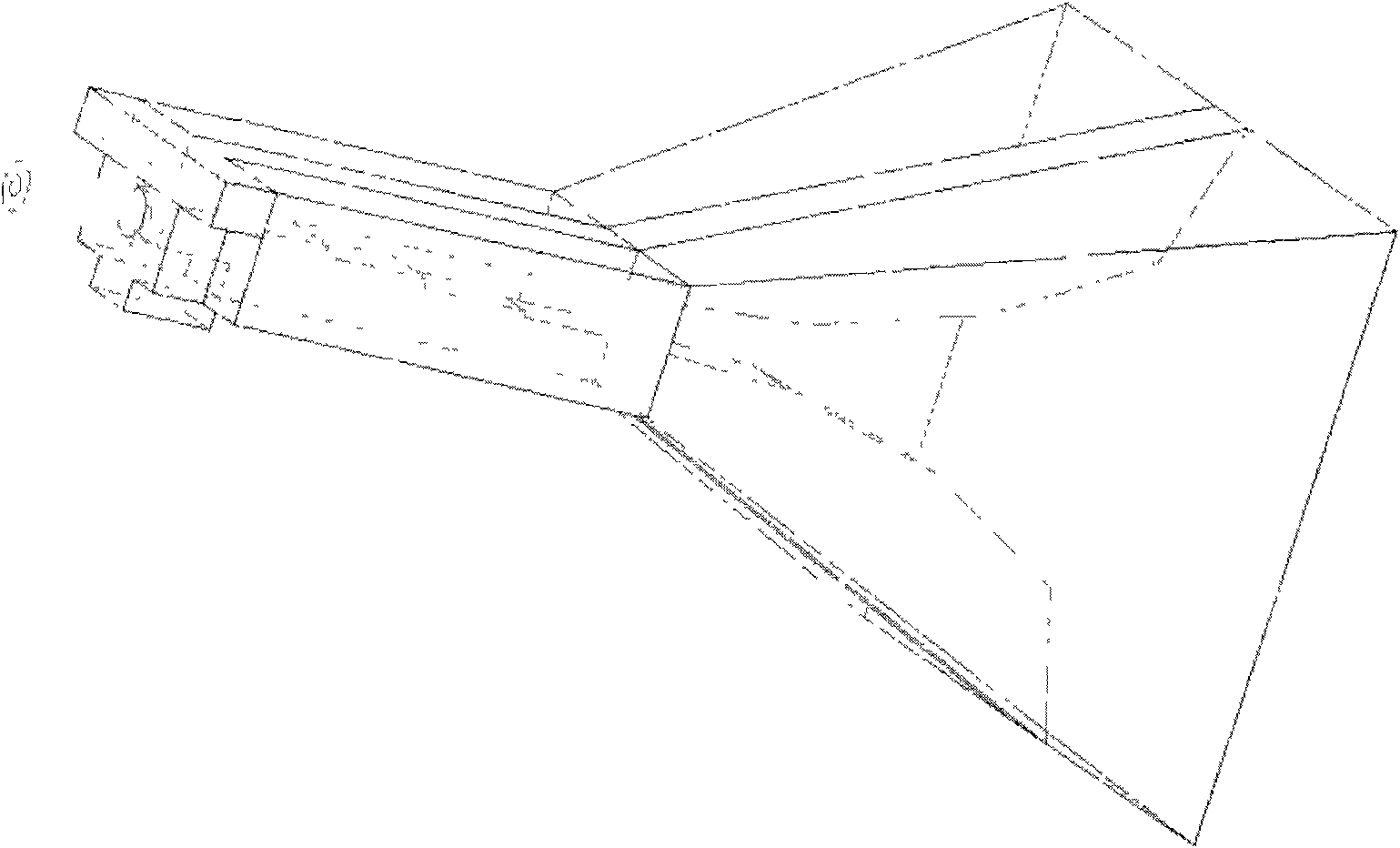

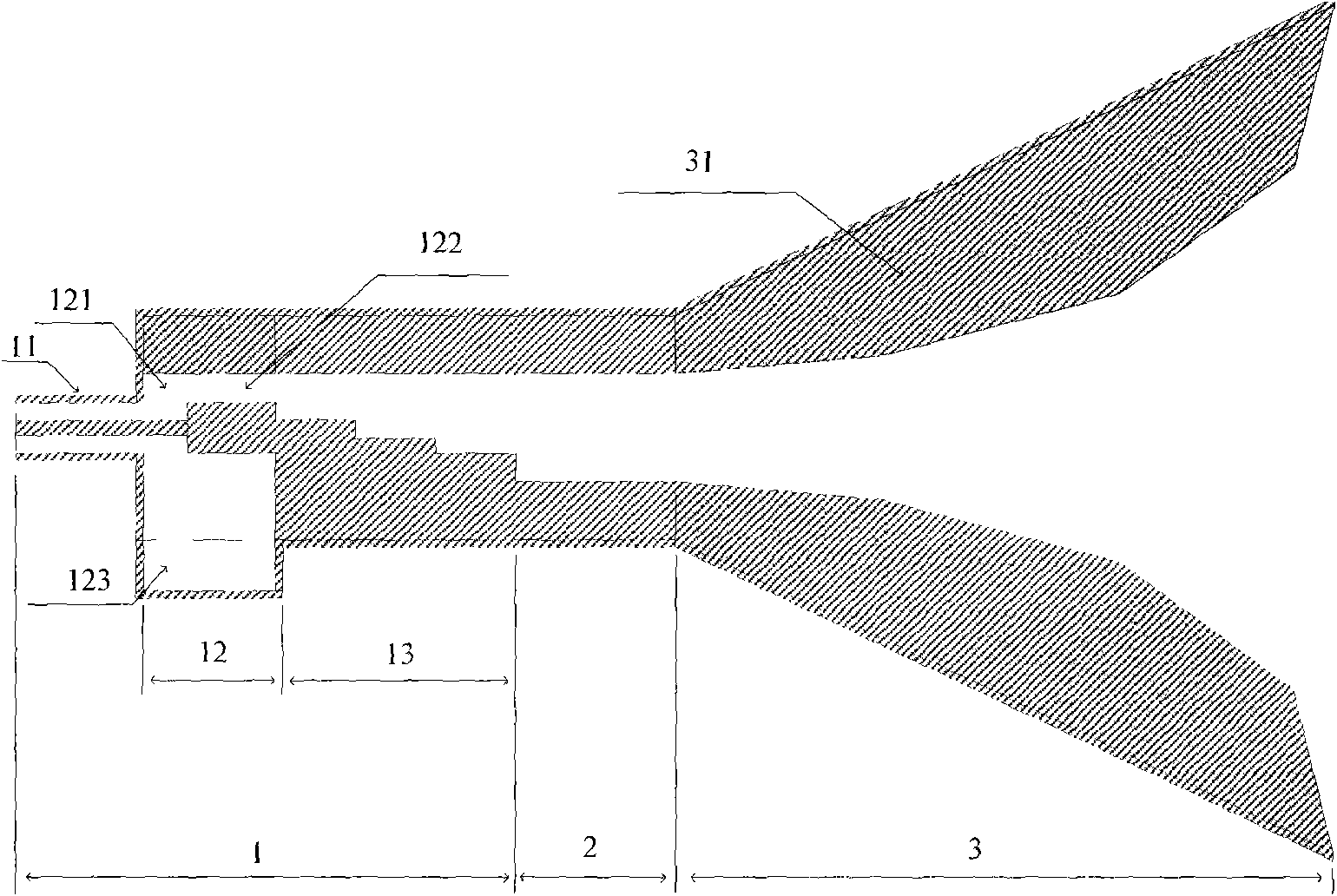

[0018] A feed-back millimeter-wave broadband double-ridge horn antenna, such as figure 1 As shown, it includes three parts: a coaxial line excitation part 1 , which includes a coaxial line 11 , a mode conversion part 12 and an impedance matching part 13 . The coaxial joint of the coaxial line 11 can be a 2.4 type or a 2.92 type coaxial joint, and its inner conductor is inserted into the inner conductor of the ridge side coaxial line 122 through the coupling hole, and glued firmly with conductive glue. The total length of the mode conversion part 12 is a quarter wavelength of the center frequency, and is divided into two parts: the former part is a shielded flat line 121 with a ridge, and the latter part is a ridged coaxial line 122, both of which are The TEM wave transmission line structure is designed with a characteristic impedance of 50Ω, and a rectangular groove, namely the ridge 123, is opened on the metal wall below the mode conversion part. The step impedance matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com