Inrush current limiter

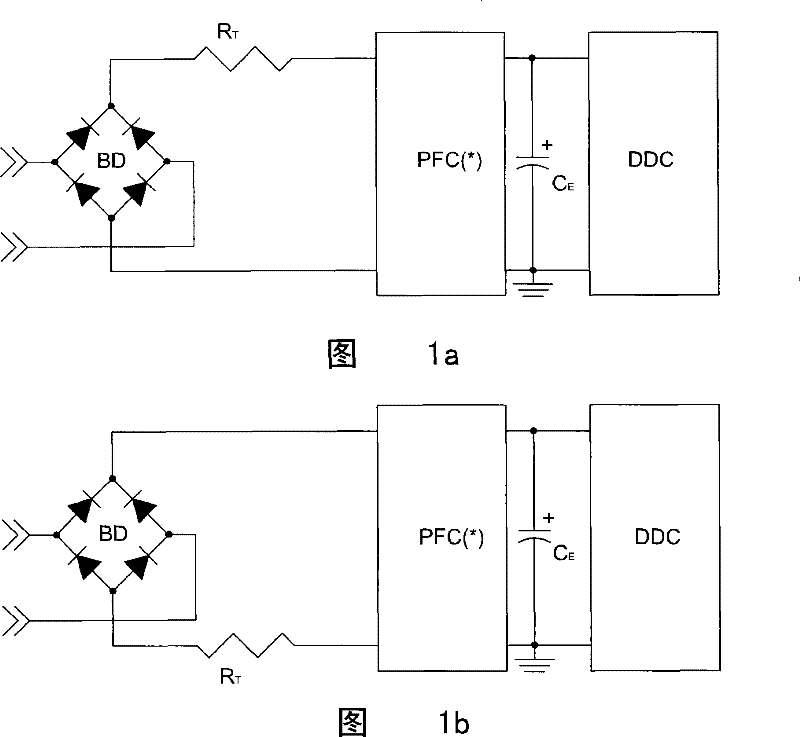

An inrush current and limiter technology, applied in electrical components, circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve the problem that the thermistor cannot simultaneously reduce the inrush current, increase, cannot Satisfaction etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

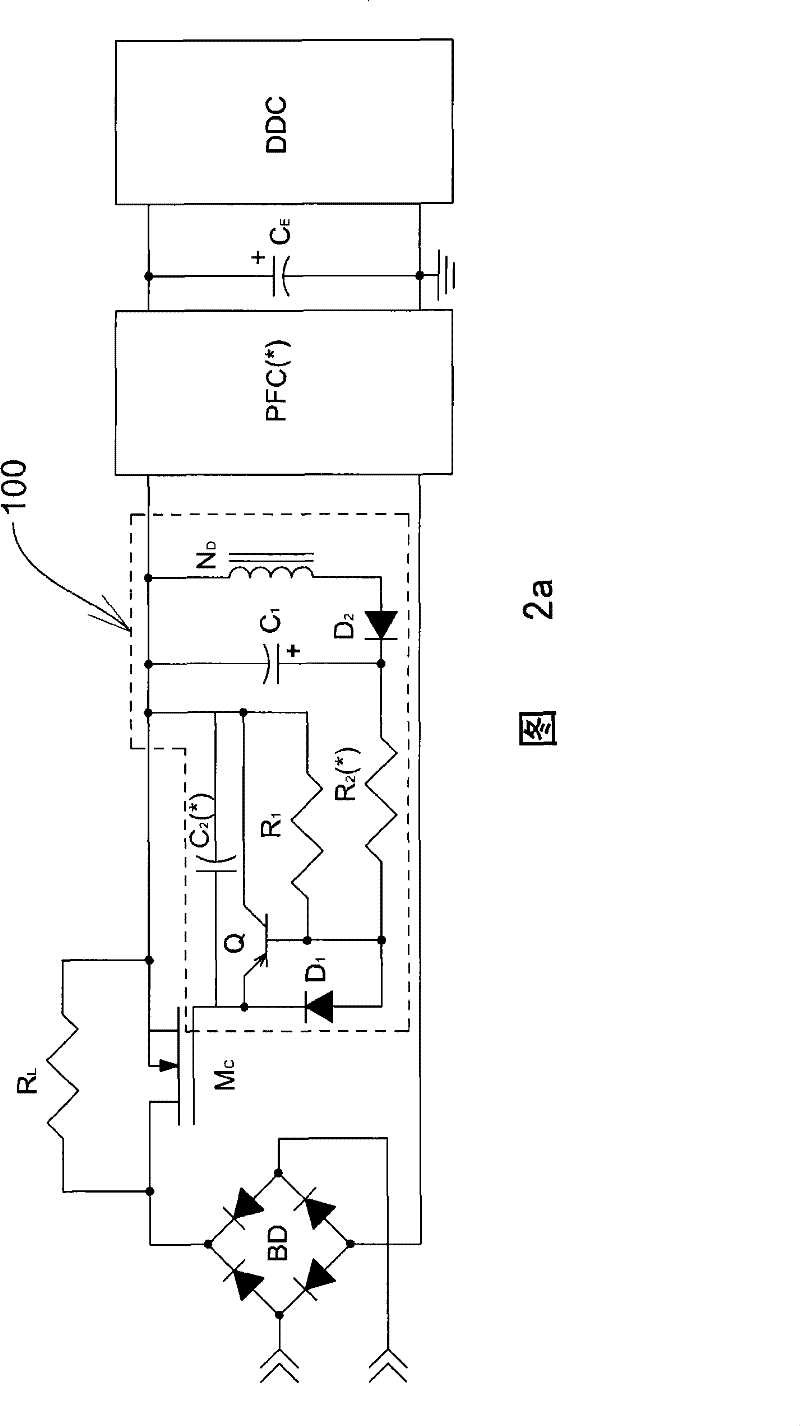

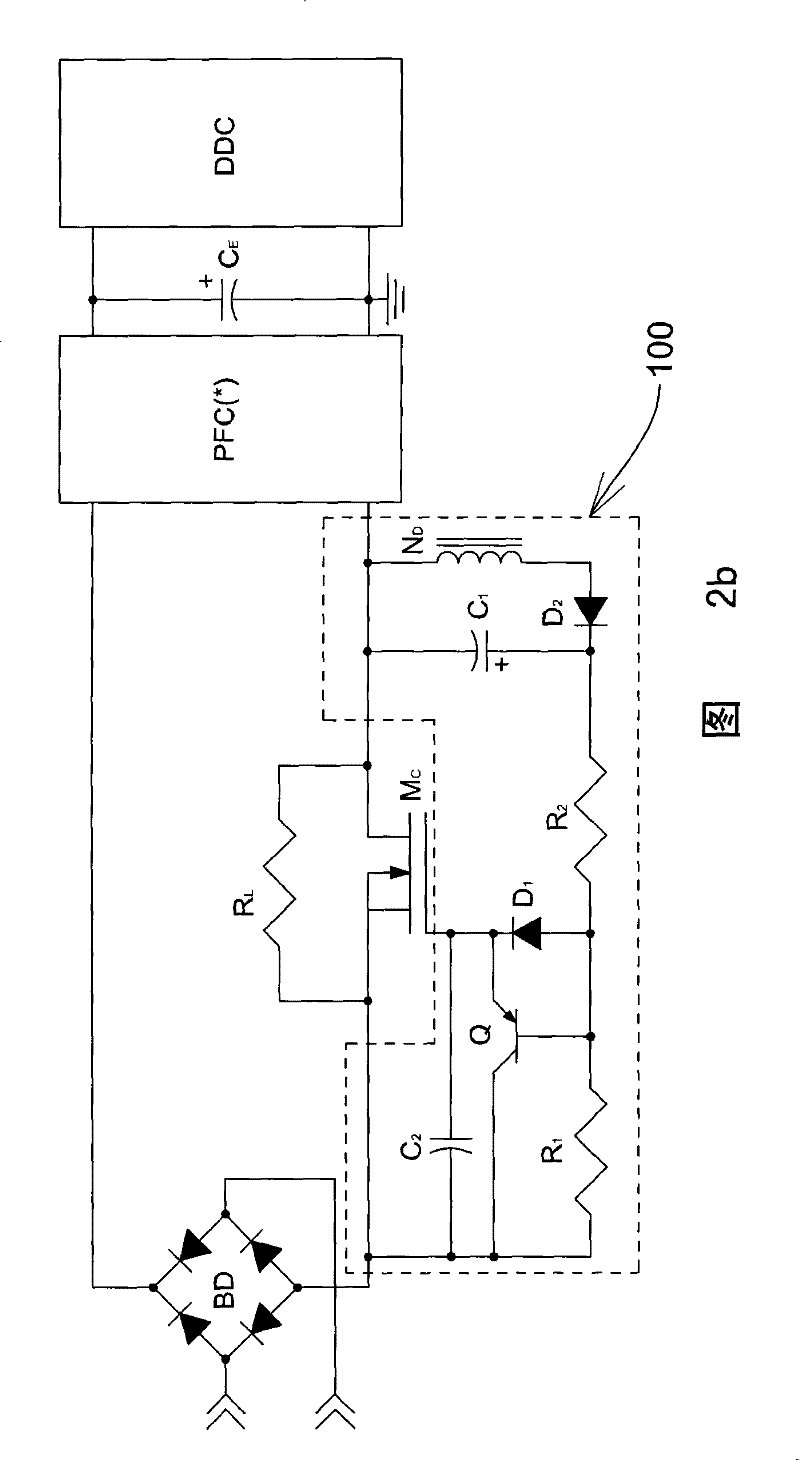

[0021] The basic circuit diagrams of the high-voltage side inrush current limiter and the low-voltage side inrush current limiter disclosed in the present invention are shown in Figure 2a and Figure 2b , the current limiting resistor R L Connected to an N-channel metal-oxide-semiconductor field-effect transistor (NMOSFET) M C Between the receiving end (drain) and the discharging end (source), the gate driver 100 is connected to M C between the gate and source. The gate driver consists of a transistor Q connected to the M C The gate and source of Q are realized by PNP bipolar transistors in the embodiment. The second capacitance C 2 The positive and negative poles of Q are connected to the emitter and collector of Q respectively. first diode D 1 The anode and cathode of the resistor are respectively connected to the base and emitter of Q, and the first resistor R 1 Connect the collector and base of Q. The first capacitance C 1 The negative pole and positive pole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com