All solid polymer battery

A bulk polymer, polymer technology, applied in batteries with solid electrolytes, secondary batteries, battery electrodes, etc., can solve the problems of insufficient cycle characteristics, insufficient prevention of battery capacity reduction, and internal resistance increase, etc. Achieve excellent ionic conductivity, difficult to reduce battery capacity, and reduce interface resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0107] In the preparation process of the polymer electrolyte solution, a lithium salt is added to the organic solvent solution of the matrix polymer to prepare the polymer electrolyte solution. Here, the organic solvent is not particularly limited as long as it can dissolve the matrix polymer and is inactive with respect to the matrix polymer and the lithium salt, and known organic solvents can be used. Examples include nitriles such as acetonitrile.

[0108] In the step of forming a precursor membrane, the polymer electrolyte solution obtained in the previous step is applied to a substrate having a smooth surface and dried to form a precursor of a dry polymer electrolyte membrane. This step can be performed in the same manner as conventional polymer electrolyte membrane formation. As a drying method, vacuum drying is preferable. In addition, if a battery electrode is used as a base material, and a precursor of a dry polymer electrolyte membrane is formed on the surface of t...

no. 1 approach

[0139] The all-solid-state polymer battery of the present invention is equipped with the negative electrode active material selected from the first embodiment of the present invention, the dry polymer electrolyte of the second embodiment of the present invention, and the amorphous material in the negative electrode interface of the third embodiment of the present invention. It has the same configuration as the conventional all-solid-state polymer battery, except that it is one or more than one of the groups constituted by the arrangement of the solid lithium nitride layer. Preferably, any one of the first embodiment of the present invention, the second embodiment of the present invention, and the third embodiment of the present invention is provided.

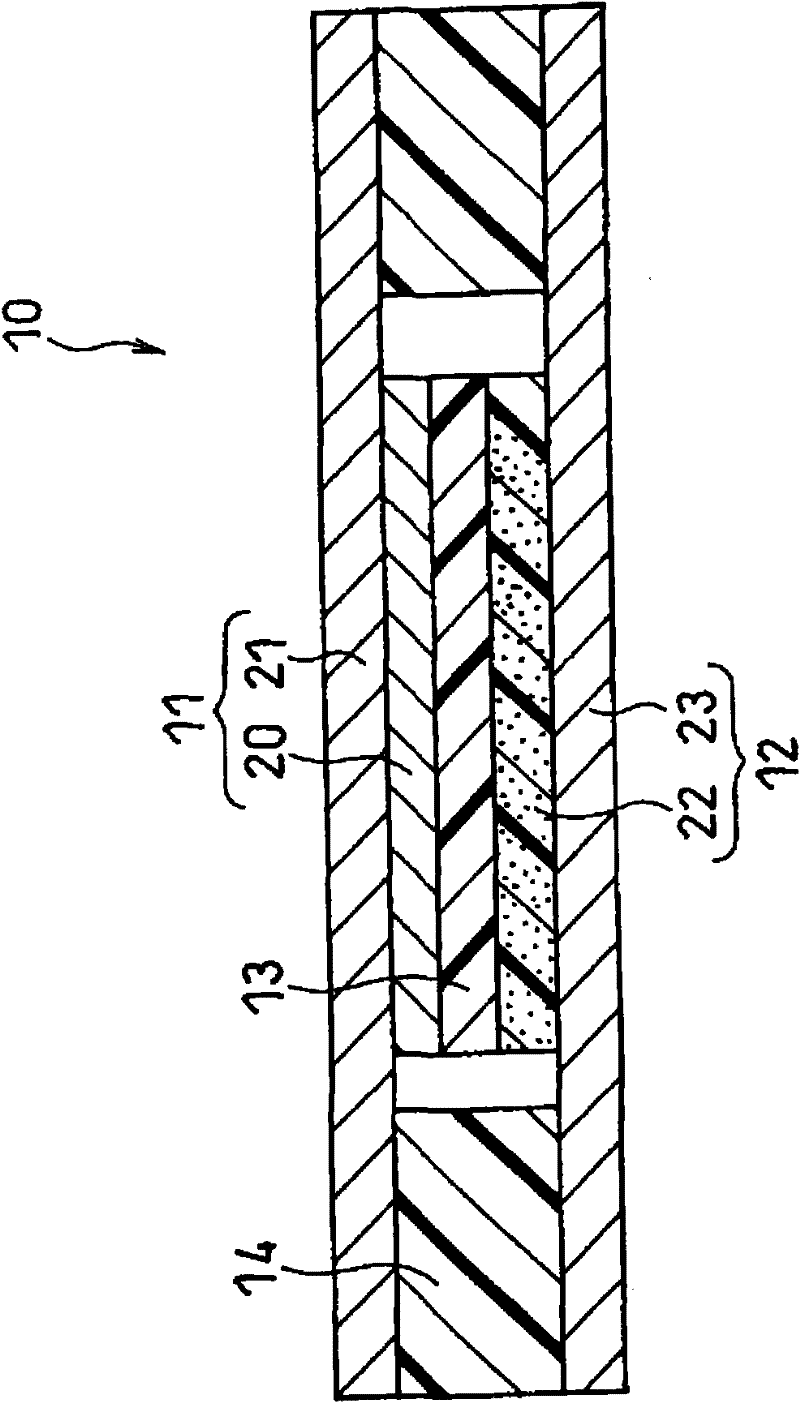

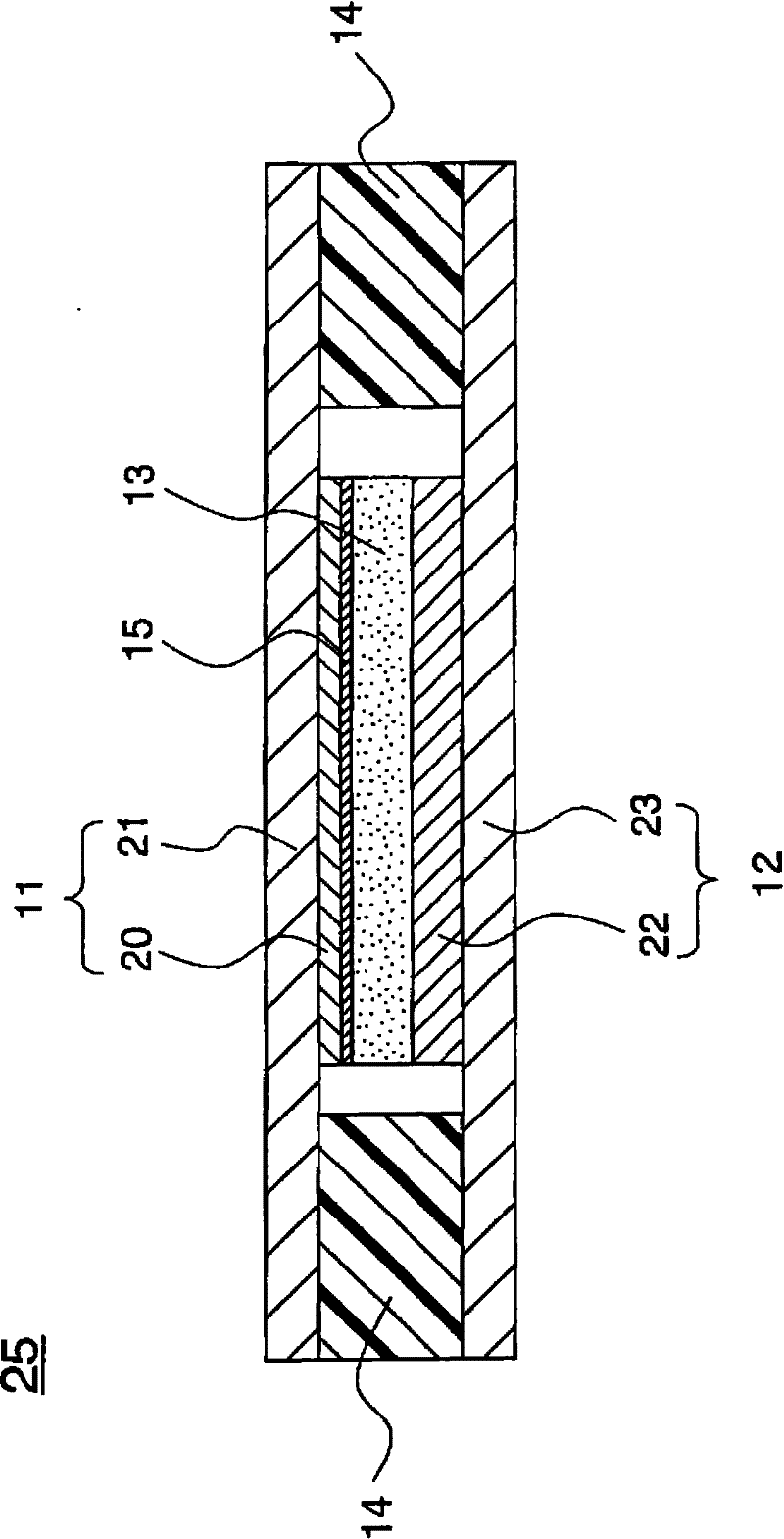

[0140] figure 2 It is a vertical cross-sectional view schematically showing the configuration of the all-solid-state polymer battery 10 of the present invention. All solid polymer battery 10 includes negative electrode 11 , po...

Embodiment 1 and comparative example 1

[0182] (1) Production of negative electrode active material and production of negative electrodes 1 to 14 and comparative negative electrodes 1 to 3

[0183] In an argon atmosphere, a lithium-based active material foil having a thickness of 300 μm was produced by an extrusion molding machine, and heated to 200° C. to melt it. The lithium-based active material in a molten state was placed on a heated copper foil having a thickness of 20 μm, and the copper foil was cooled to room temperature at the cooling rate described in Table 1.

[0184] Next, after a guide (10 mm in diameter) of a predetermined size is placed on the surface of the copper foil on which the lithium-based active material is provided, the lithium-based active material is pressed and rolled to a thickness of about 100 μm, and is aligned with the guide. The same size, and crimped to the copper foil as the negative electrode current collector. The lithium-based active material foil obtained by rolling was heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com