Method for blending and setting wood

A wood and bending technology, applied in the field of bending and shaping of wood, can solve the problems of high pressure requirements and long process time, and achieve the effects of high dimensional stability, simple process, and expansion of the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Taking Fraxinus mandshurica as an example, the bent and deformed foot of a chair was made, and the manufacturing method was as follows:

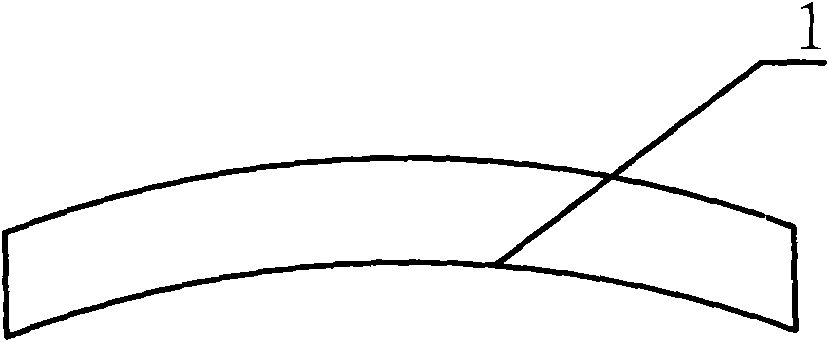

[0048] Such as figure 1 , figure 2 As shown, the size of the ash square timber is 950mm×47mm×32mm through the material production. Take the above-mentioned square material into a cooking tank, steam it with 100℃ steam for 140min, and set the pressure to 0.4Mpa; After softening the ash square material wool, immediately pressurize the ash with mold, steel belt, stopper, etc. Bend and deform as attached image 3 The curve shape shown; put the bent and deformed manchurian ash wool together with molds, steel strips, etc. into the integrated drying and ultra-high temperature heat treatment kiln for drying and ultra-high temperature heat treatment. The drying stage is when the dry bulb temperature is about 55 Begin at ℃, and then gradually increase the temperature to about 125℃. The temperature difference between the dry and wet bul...

Embodiment 2

[0052] Example 2: Taking Chinese fir as an example, the bent and deformed back foot of a chair is made, and the manufacturing method is as follows:

[0053] Through timber making, the size of Chinese fir square timber is 950mm×47mm×32mm. Take the above-mentioned square material into a cooking pot and boil it in hot water at 80°C for 130 minutes; after the fir wool is softened, immediately use a mold, steel belt, stopper, etc. to press and bend the ash to form a curved shape; The bent and deformed fir wool, together with molds, steel strips, etc., are put into the integrated drying and ultra-high temperature heat treatment kiln for drying and ultra-high temperature heat treatment. The drying stage is that the dry bulb temperature starts from about 45°C, and then the temperature is raised to about 115℃, the temperature difference between the dry and wet bulbs gradually expanded to 25℃, reducing the moisture content of the wood to 4%~5%, and then the dry bulb was quickly heated to 1...

Embodiment 3

[0055] Example 3: Taking yellow rattan as an example, the bent and deformed back foot of a chair is made, and the manufacturing method is as follows:

[0056] Through lumber making, the specifications of yellow rattan square lumber are 8000mm long and 70mm in diameter. Take the above round wood into a cooking tank, steam it with 100℃ steam for 20 minutes, and set the pressure to 0.5Mpa; After the yellow vine round wood wool is softened, immediately press the yellow vine with mold, steel belt, stopper, etc. Bending and deforming into a curved shape; Put the bent and deformed yellow rattan wool together with molds, steel strips, etc. into the integrated drying and ultra-high temperature heat treatment kiln for drying and ultra-high temperature heat treatment. The drying stage is when the dry bulb temperature is about 55°C At the beginning, the temperature was raised to about 125°C in stages, and the temperature difference between the dry and wet bulbs was gradually expanded to 25°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com