Hydraulic damper for elevator

A technology of hydraulic shock absorber and hydraulic shock absorber, which is applied to liquid shock absorbers, elevators in buildings, shock absorbers, etc. Small depth dimension, the effect of reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

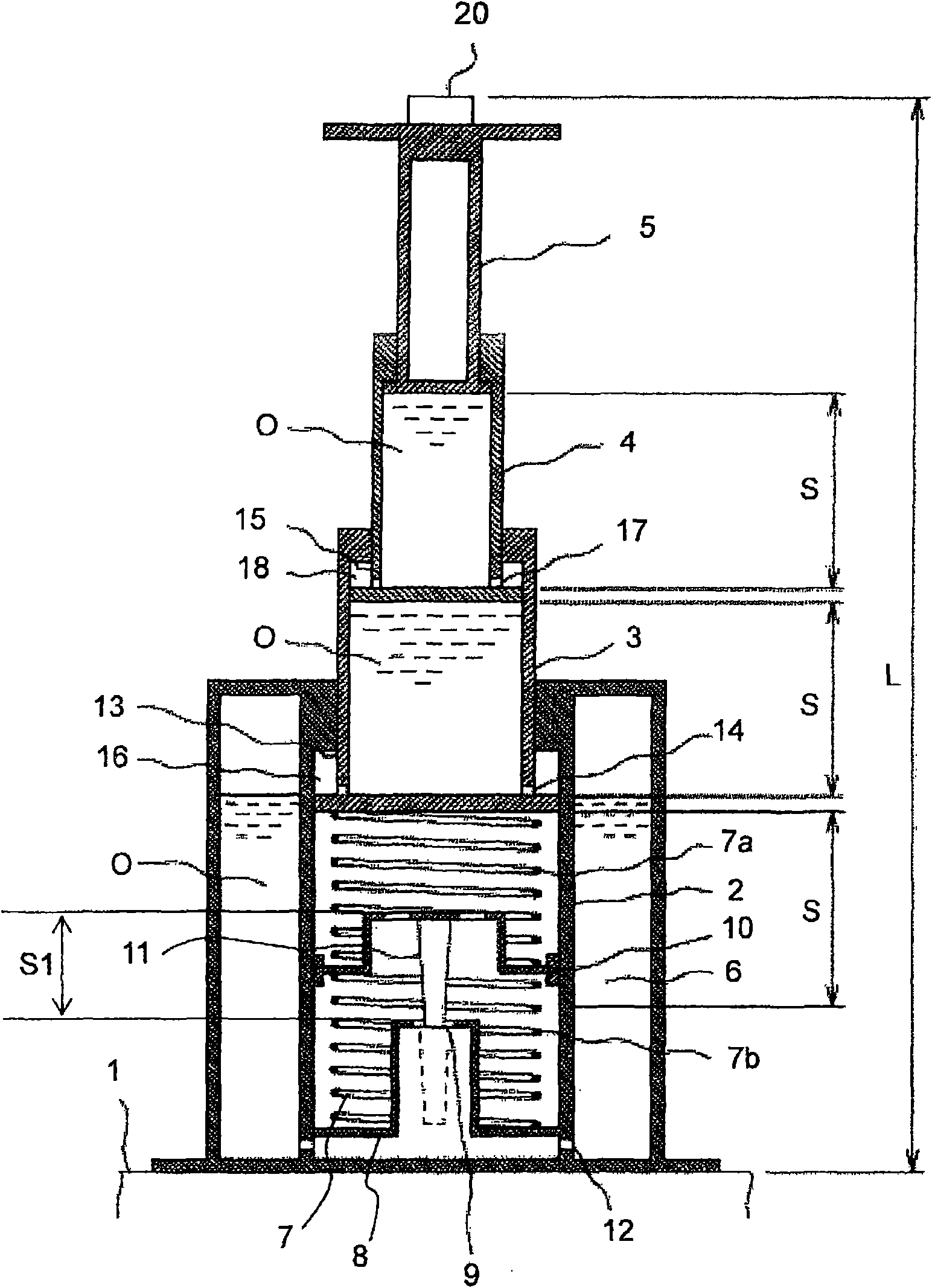

[0041] Embodiments of the hydraulic shock absorber for an elevator according to the present invention will be described below with reference to the drawings.

[0042] figure 1 It is a longitudinal sectional view showing one embodiment of the elevator hydraulic shock absorber according to the present invention, figure 2 is a schematic diagram showing the compression state of the hydraulic shock absorber.

[0043] Such as figure 1 As shown, the hydraulic shock absorber for an elevator in this embodiment is composed of a hydraulic cylinder 2 and a plurality of plungers. The plug 3, the second plunger 4 and the third plunger 5 are fitted in the hydraulic cylinder 2 in a manner that can expand and contract in the up and down direction, and the diameters of the plurality of plungers decrease sequentially from the outside to the inside, and they are stacked in a concentric manner.

[0044] The hydraulic cylinder 2 has: an oil tank 6, which is arranged on the outside of the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com