Screw applied to composite material

A composite material and screw technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve problems such as low locking force, toppled partition walls, unsatisfactory combination of self-tapping screws and metal plates, etc., to achieve locking The effect of fast speed and improved safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following, the structural composition and the effect that can be produced by the screw applied to the composite material of the present invention are described in detail as follows with preferred embodiments in conjunction with the accompanying drawings:

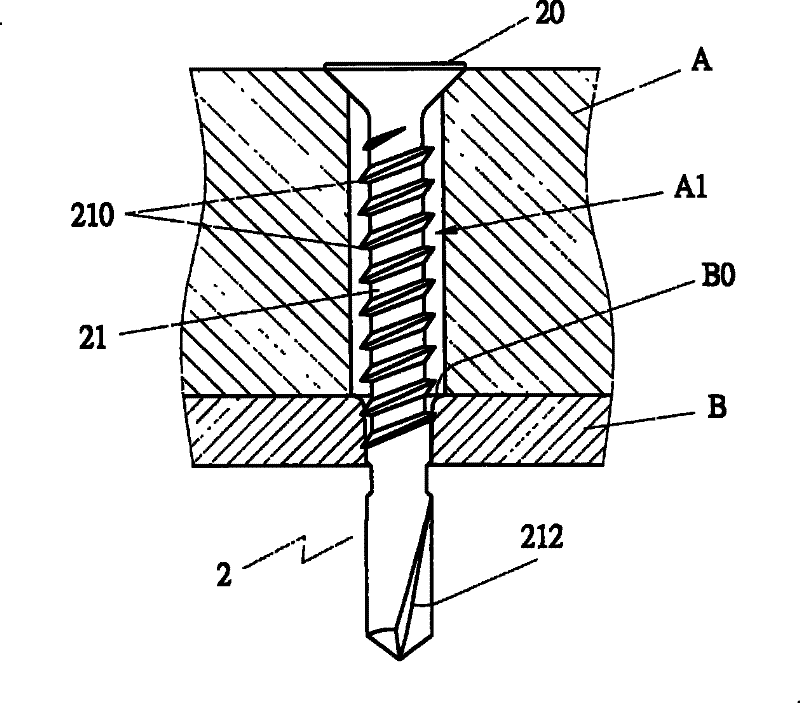

[0044] Such as Figure 6-10 Shown is a view and a cross-sectional view of Embodiment 1 of the present invention. Embodiment 1 of the present invention is applied to a screw 3 made of composite materials, including a cap 30 , a stem 31 and a cutting wing 34 .

[0045] The cap portion 30 is disposed on the top of the rod portion 31, and the cap portion 30 can be in any shape, and can cooperate with various locking tools. A plurality of cutting surfaces 301 are provided on one side 300 of the cap 30 , and the composite material can be cut by using the cutting surfaces 301 and the cap 30 can enter the composite material.

[0046] The rod portion 31 is provided with a thread section 310. The shape of the thread sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com