Adjustable pressurization system of serial-parallel boilers of big and small turbochargers

A turbocharger and turbine technology, applied in the field of supercharging systems, can solve the problems of limited adaptability and insufficient variation range of diesel engines, and achieve the effect of optimal matching and wide variation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

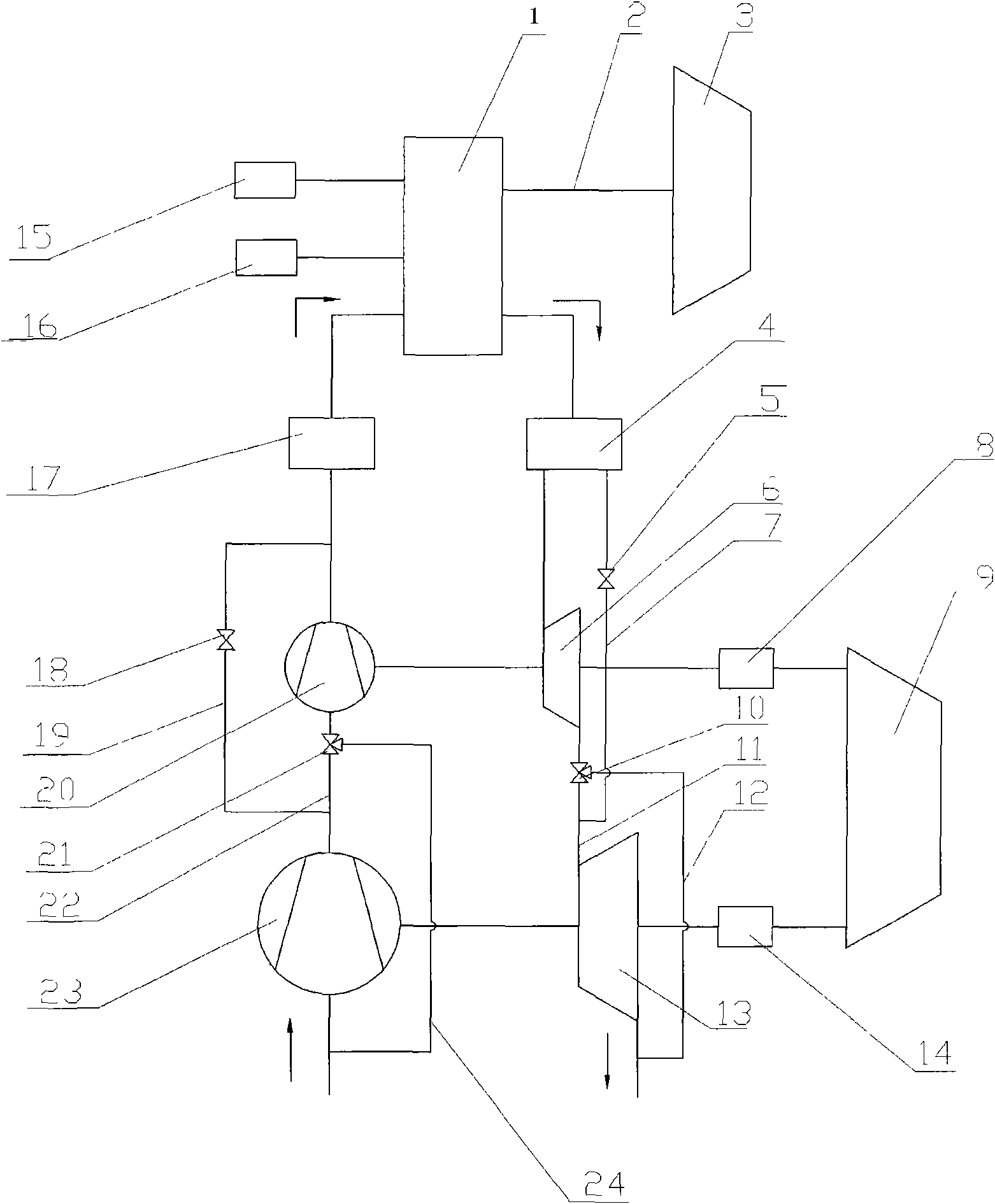

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0016] like figure 1 As shown, the present invention includes: a boiler 1, a steam output piping system 2, a main steam turbine 3, a flue gas purification device 4, a high-pressure turbine bypass pipeline bypass valve 5, a high-pressure turbine 6, and a high-pressure turbine bypass pipeline 7. No. 1 transmission mechanism 8. Auxiliary steam turbine 9. High and low pressure turbine connection pipeline flow switching control valve 10. High and low pressure turbine connection pipeline 11. Low pressure turbine bypass pipeline 12. Low pressure turbine 13. No. 2 speed change mechanism 14. Fuel supply system 15. Boiler water supply mechanism 16. Air conditioning baffle 17. High pressure compressor bypass pipeline bypass valve 18. High pressure compressor bypass pipeline 19. High pressure compressor 20. High and low pressure compressors The flow switch control valve 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com