Method for fast analyzing pesticide residue in fruits and vegetables

A technology with many pesticide residues and rapid analysis, applied in the field of food testing, can solve the problems of low sample preparation efficiency, restricting detection efficiency, time-consuming and labor-intensive problems, and achieve the effect of simple operation, less solvent consumption, and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

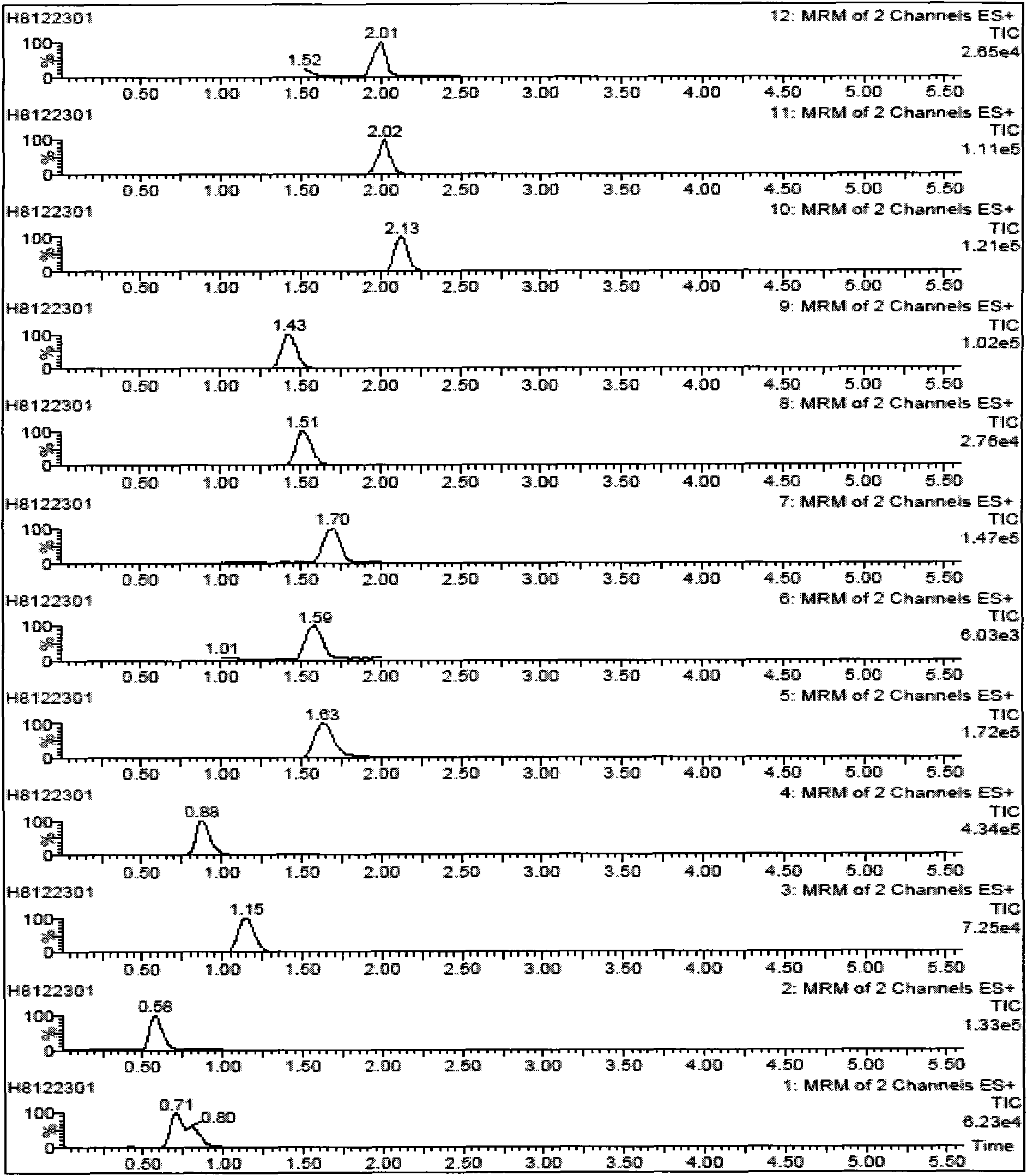

Image

Examples

Embodiment 1

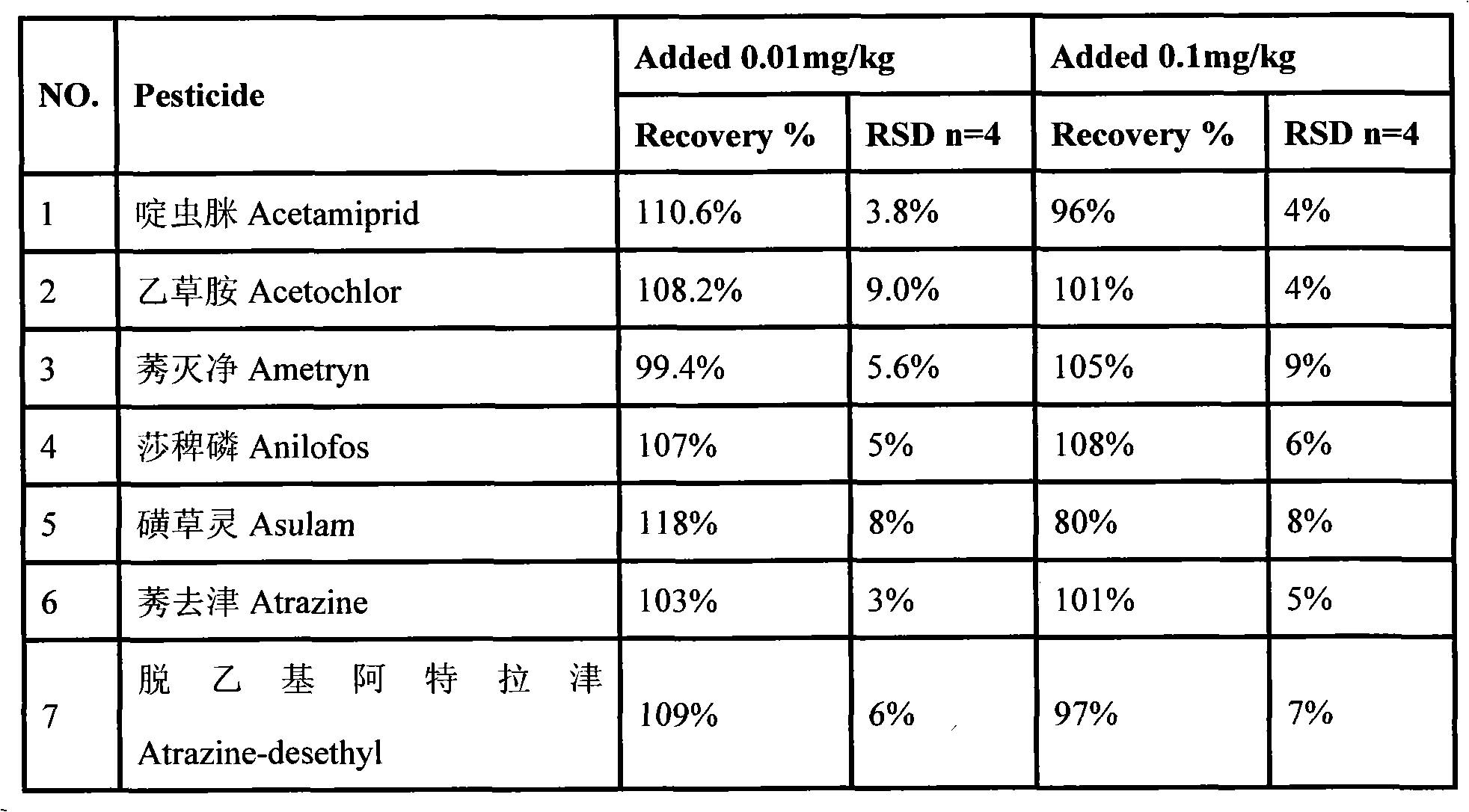

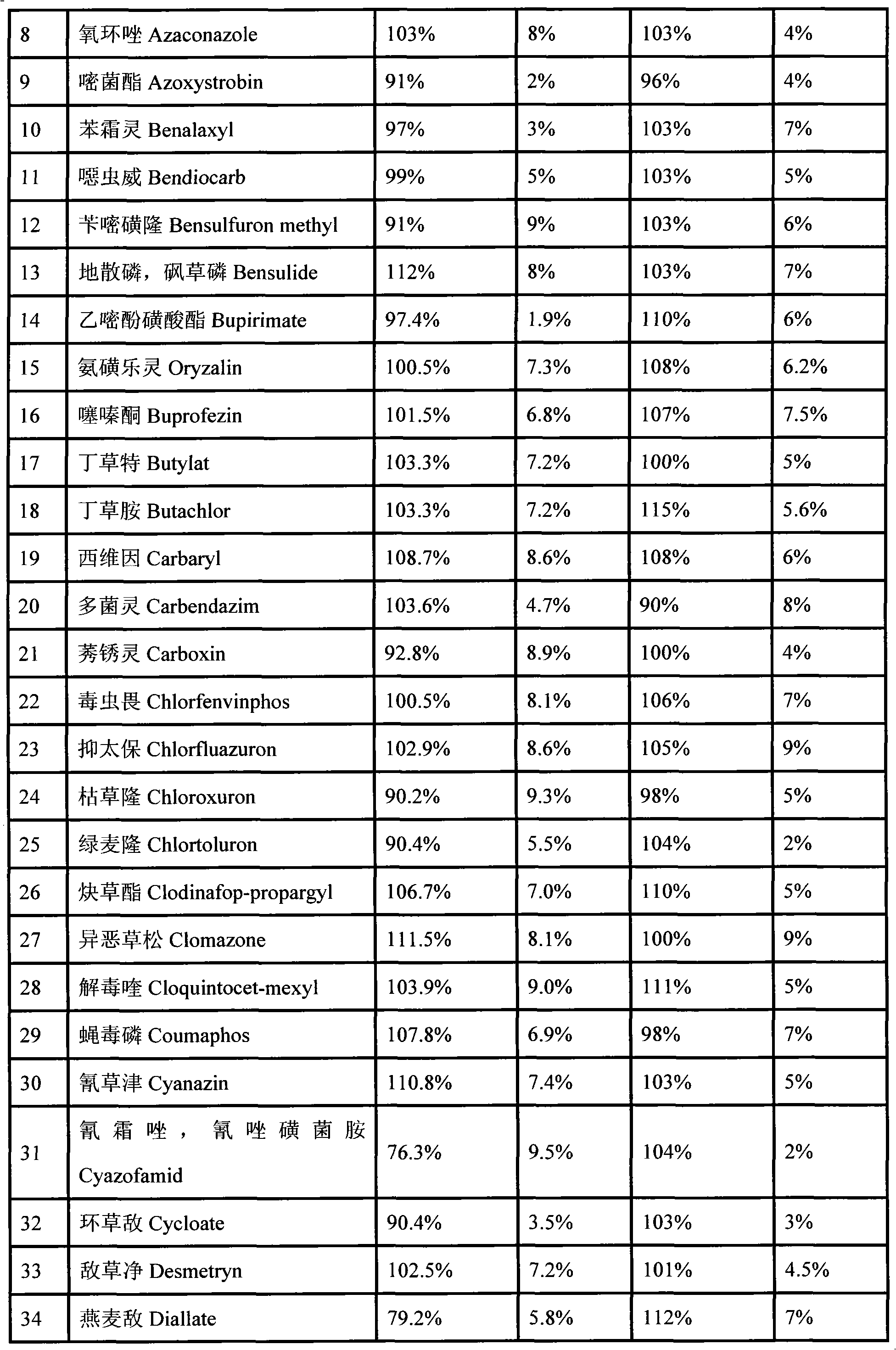

[0026] Example 1, a rapid analysis method for pesticide residues in fruits and vegetables, taking green asparagus as an example, preparing 130 kinds of pesticide mixed standard solutions, adding 0.01mg / kg and 0.1mg / kg pesticide standard substances for recovery, each Each content level was repeated 4 times, then extracted, and 15.0 g of uniformly prepared samples were weighed, added to a 50 mL centrifuge tube containing 1.5 g of anhydrous sodium acetate and 6 g of anhydrous magnesium sulfate, and then added with 15 mL of 1% acetic acid acetonitrile solution, vigorously Shake for 1min, after ultrasonic extraction for 15min, centrifuge at 5000r / min for 1min; purify, transfer 10mL of acetonitrile extract to a 15mL centrifuge tube filled with mixed fillers in different proportions, the filler is 500mg PSA and graphitized carbon in a mass ratio of 1:1, Shake for 1min, centrifuge at 5000r / min for 1min, absorb 5mL of purified solution, concentrate and evaporate to dryness, and make up ...

Embodiment 2

[0038] Example 2, a rapid analysis method for multiple residues of pesticides in fruits and vegetables, taking edamame as an example, preparing 28 kinds of pesticide mixed standard solutions, adding and recovering at a level of 0.02 mg / kg, repeating 4 times for each content level, and then extracting , Weigh 15.0g of the uniformly prepared sample, add it to a 50mL centrifuge tube containing 1.5g of anhydrous sodium acetate and 6g of anhydrous magnesium sulfate, then add 15mL of 1% acetic acid acetonitrile solution, shake vigorously for 1min, and after ultrasonic extraction for 15min, 5000r / min centrifugation for 1min; purification, transfer 10mL of acetonitrile extract to a 15mL centrifuge tube equipped with mixed fillers in different proportions, the filler is 500mg of graphitized carbon, PSA, C18 mixed in a mass ratio of 1:2:2, shake for 1min, 5000r / min centrifuged for 1min, draw 5mL of purified solution, concentrated and evaporated to dryness, the volume ratio of acetonitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com