Active element matrix substrate

An active element and matrix technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as the decrease of pixel aperture ratio and affect the brightness performance of LCD 100, so as to increase the aperture ratio, avoid light leakage, and improve the pixel aperture ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

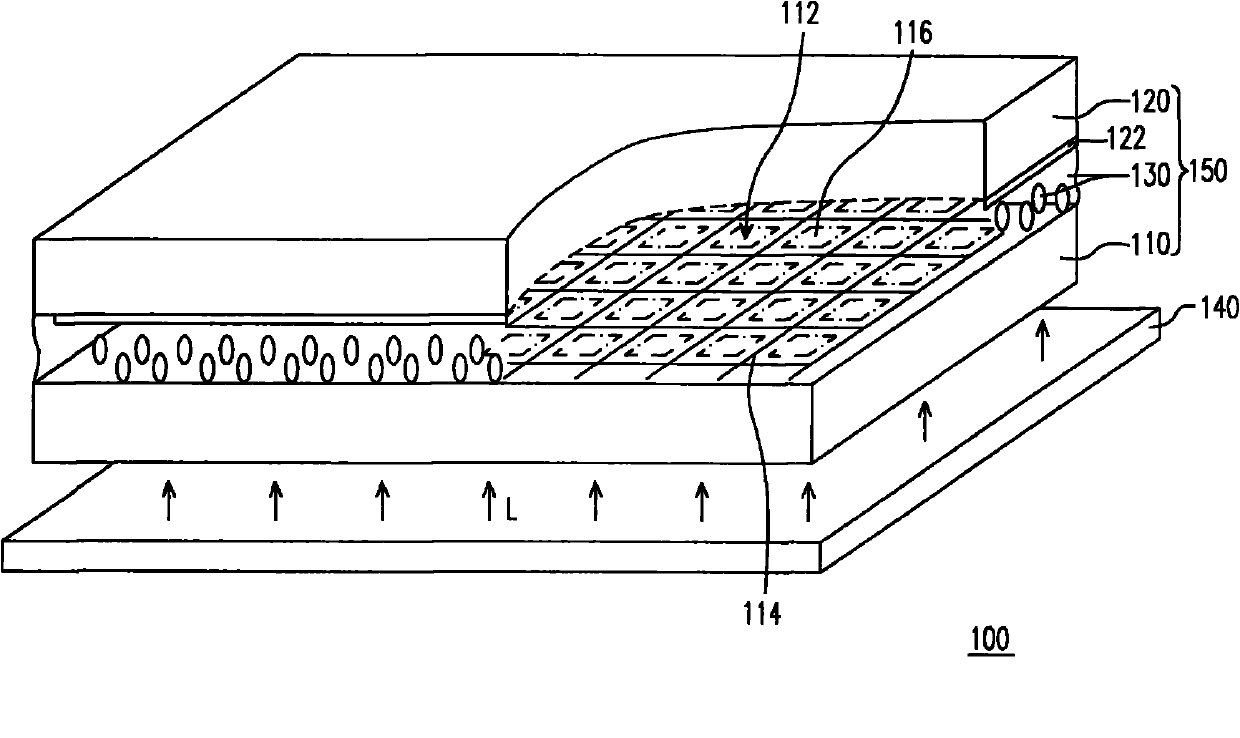

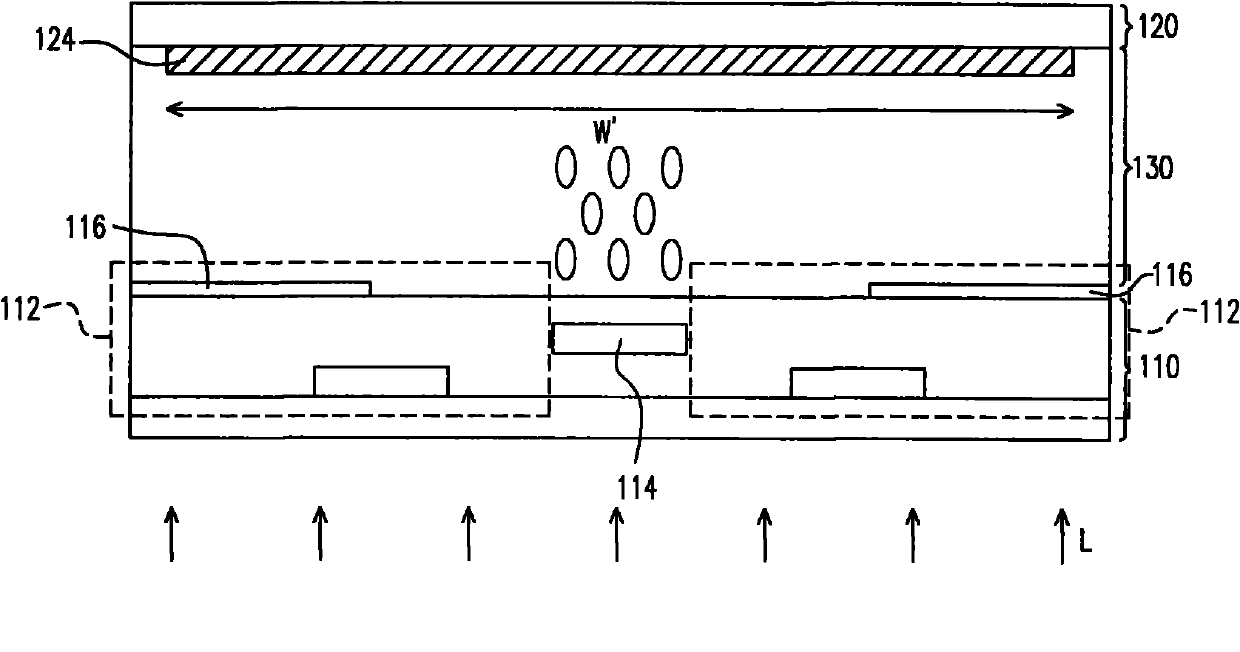

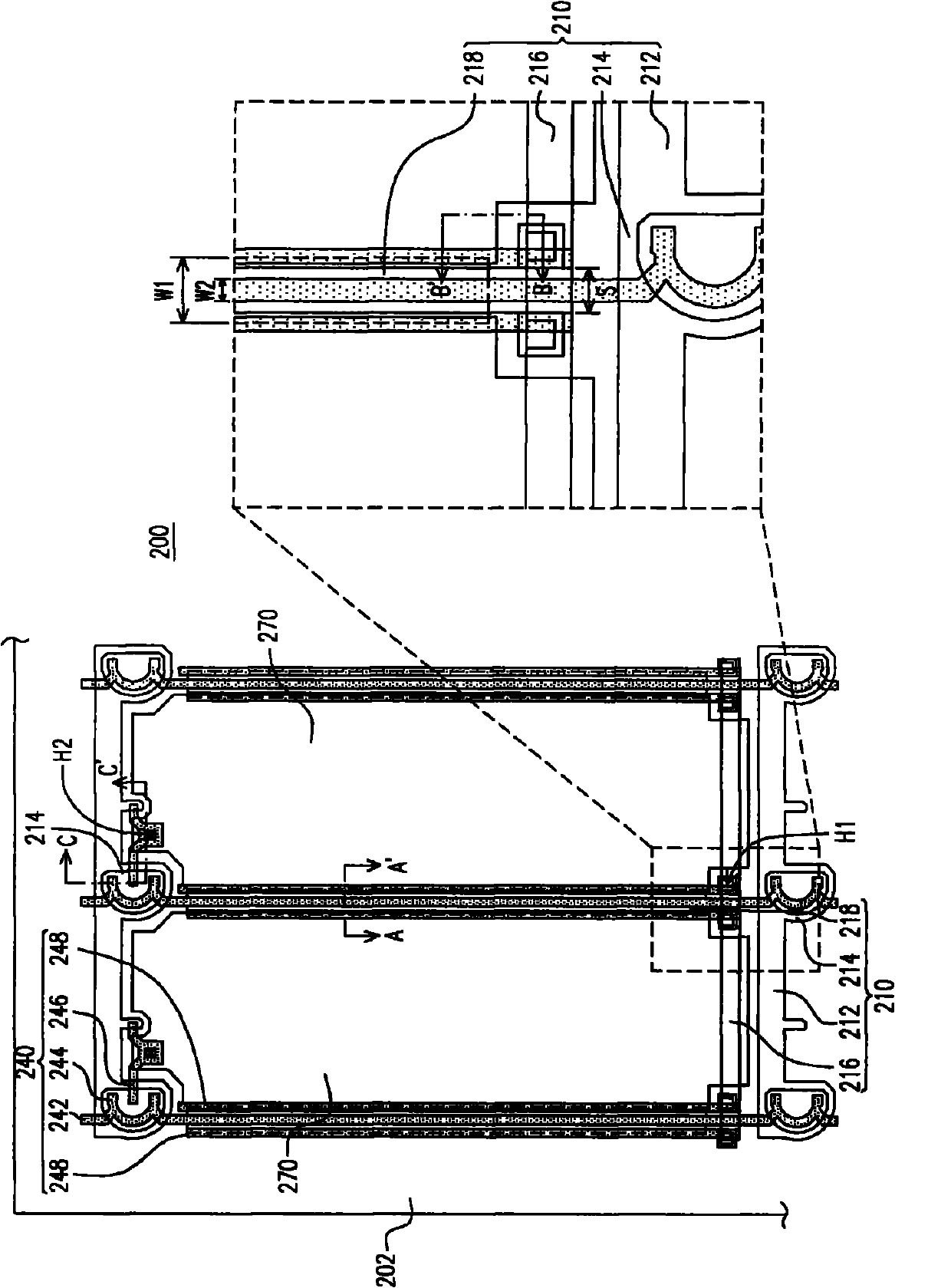

[0072] figure 2 It is a partial top view of an active element matrix substrate according to the first embodiment of the present invention, Figure 3A will be figure 2 The partial cross-sectional view of the active element matrix substrate applied to the liquid crystal display in Figure 3A The position of the mid-section is roughly along the figure 2 The corresponding position of the active element matrix substrate 200 of the cross-section line AA' in the middle. Please also refer to figure 2 and Figure 3A The active device matrix substrate 200 of this embodiment includes a substrate 202 , a first patterned conductor layer 210 , a dielectric layer 230 , a second patterned conductor layer 240 , a protection layer 260 and a plurality of pixel electrodes 270 .

[0073] Please also refer to figure 2 and Figure 3A , the first patterned conductor layer 210 is disposed on the substrate 202, the first patterned conductor layer 210 includes a plurality of scanning lines 2...

no. 2 example

[0086] Figure 4 It is a partial top view of an active element matrix substrate according to the second embodiment of the present invention, please refer to Figure 4 The active element matrix substrate 400 of this embodiment is similar to the active element matrix substrate 200 of the first embodiment. In the pixel unit of the active element matrix substrate 400 of this embodiment, the storage capacitor is in the form of a storage capacitor on the scanning line 212 type (Cst on scan line). For clarity, the same components in this embodiment and the first embodiment are denoted by the same symbols.

[0087] Figure 5 for Figure 4 Schematic cross-section along the section line BB'. Please refer to Figure 5 , in this embodiment, the position of the first contact opening H1 of the dielectric layer 230 is opened above the scan line 212 , in other words, the first contact opening H1 respectively exposes a part of the scan line 212 . Moreover, each strip capacitor electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com