Portable fruit picking machine capable of automatic gripping and cutting

A portable, picking machine technology, applied in the direction of picking machine, harvester, computer control, etc., can solve the problems of increased energy consumption, difficult rack replacement, low practicability, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

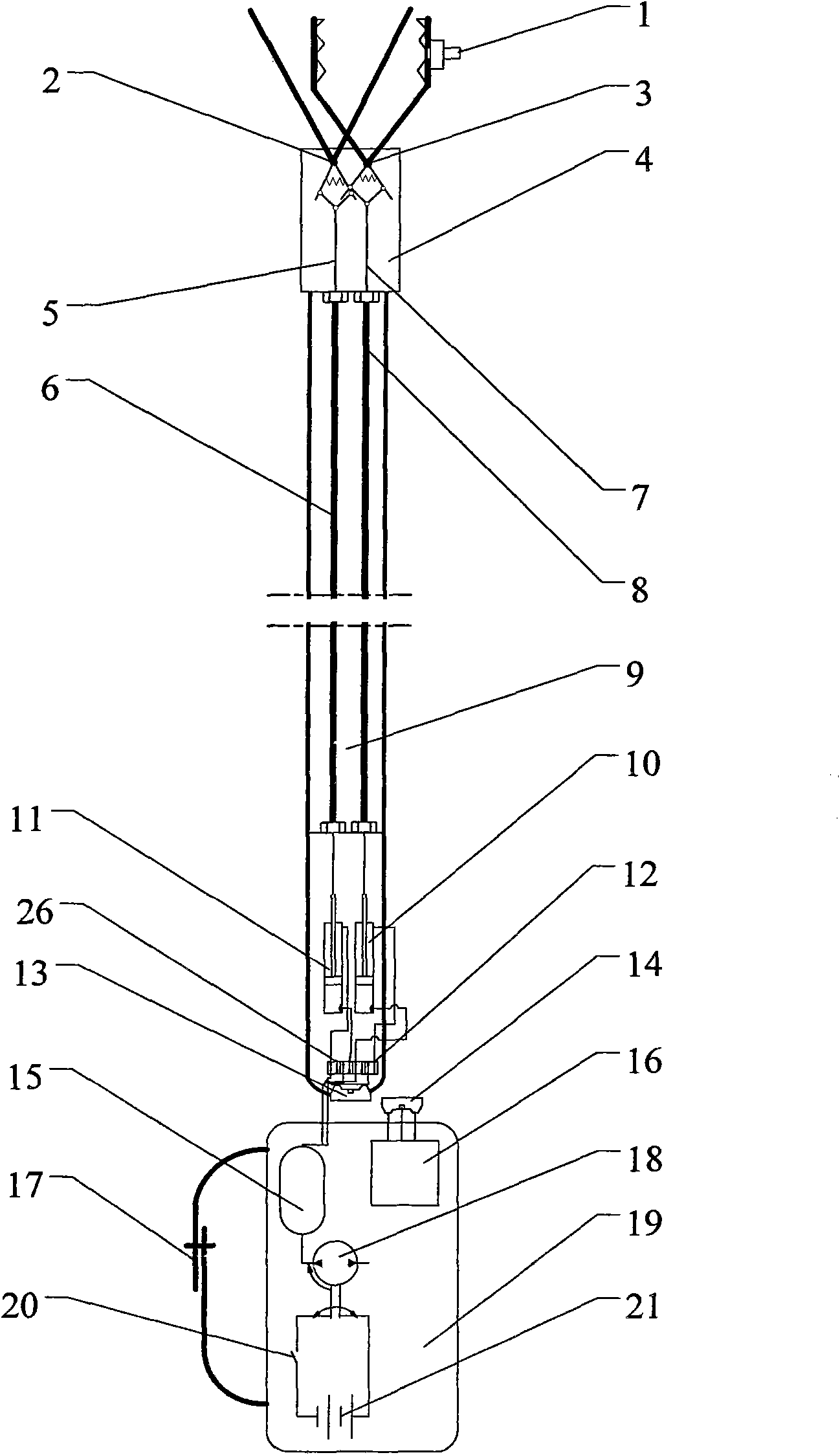

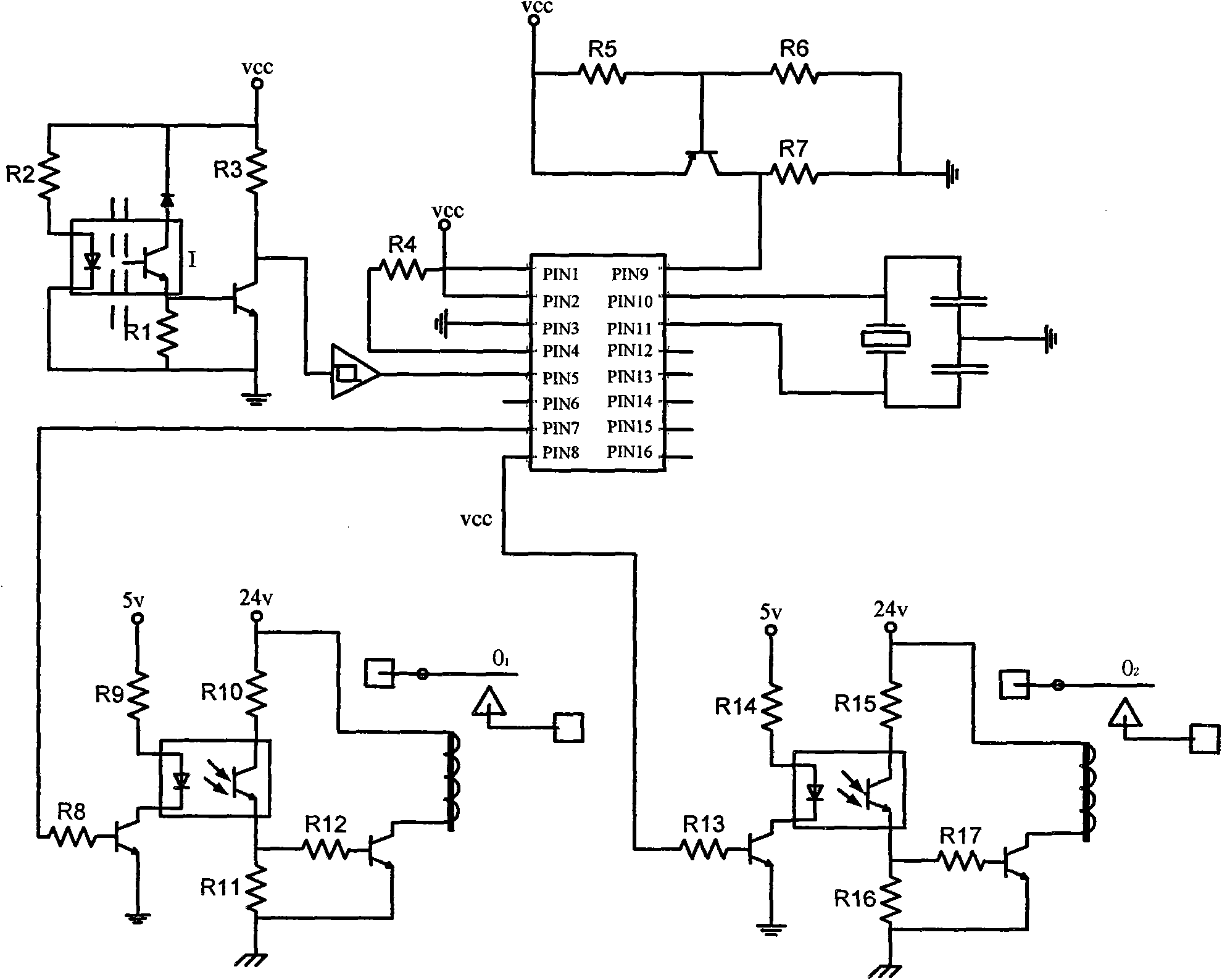

[0025] A kind of portable automatic clamping and cutting fruit picking machine of present embodiment, as figure 1 As shown, it includes a picking mechanism, a transmission mechanism and a driving mechanism connected in sequence, wherein the picking mechanism is provided with a stem detector 1, and the driving mechanism is provided with a corresponding measurement and control circuit 16; the driving mechanism is a pneumatic driving mechanism, including cutting Cylinder 11 and clamping cylinder 10, cutting cylinder 11, clamping cylinder 10 are connected successively with gas tank 15, air pump 18 through corresponding cutting solenoid valve 26, clamping solenoid valve 12 respectively; Cutting cylinder 11 and clamping cylinder 10 are located at The handle end of picking rod body 9, air tank 15, air pump 18 and measurement and control circuit 16 are located in picking body 19.

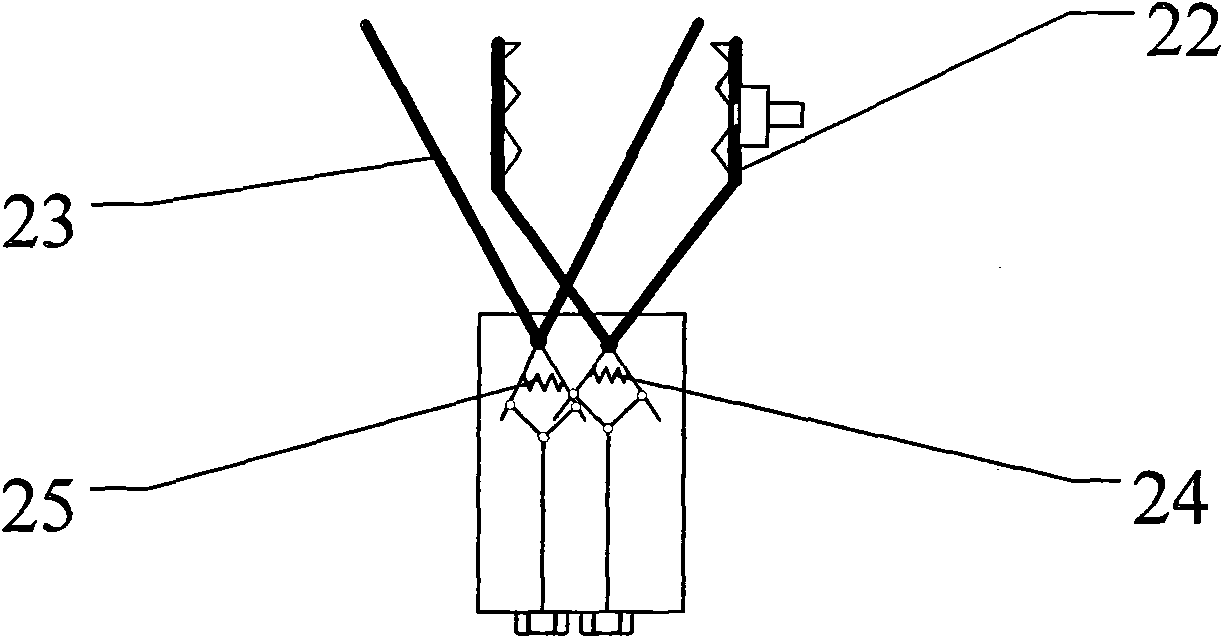

[0026] The picking mechanism includes a clamping assembly 3 and a cutting assembly 2 that are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com