Method for manufacturing palm-bamboo charcoal mattress

A manufacturing method and technology of mangosteen, which are applied in mattresses, spring mattresses, stuffed mattresses, etc., can solve the problems of single function effect, weakened elasticity, and easy to harden, and can improve sleep quality, adjust dry humidity, Fatigue relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

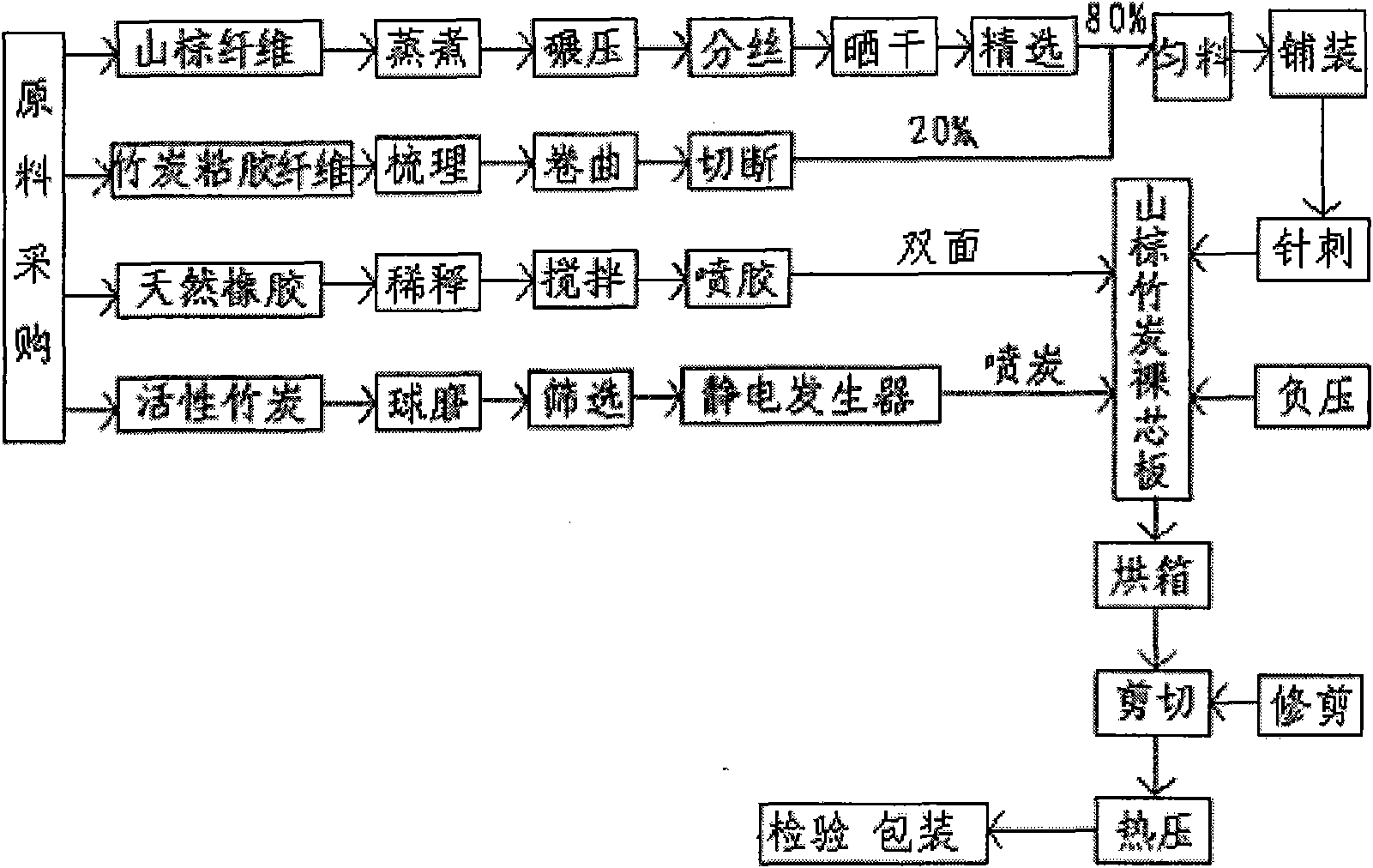

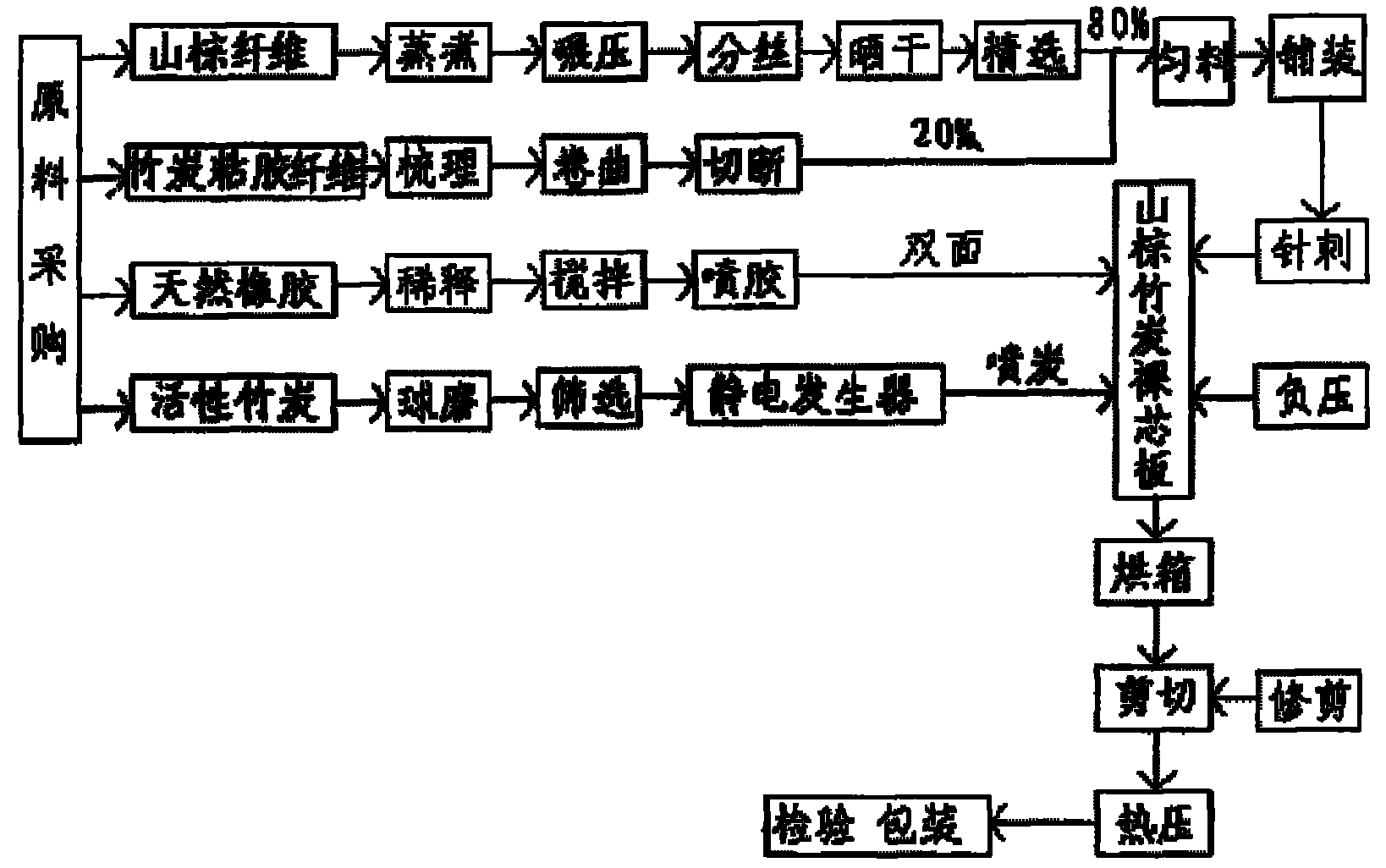

[0010] Below in conjunction with this accompanying drawing and embodiment the present invention will be further described, in accompanying drawing

[0011] 1. Raw material procurement: it is the main raw material for producing the mountain palm bamboo charcoal mattress core of the present invention,

[0012] (1) palm fiber sheet, select the palm sheet of the mature palm leaf tip more than three years for use, and remove moth-eaten, rotten, rotten parts;

[0013] (2) Bamboo charcoal viscose fiber, which is a functional non-woven material recently developed and produced, is made of wood, cotton, plant leaf stem fiber and activated bamboo charcoal, and is made after yellow acidification, which itself has activated bamboo charcoal For the excellent effect, ordinary strong wire with a diameter of 0.45-0.65 mm should be selected to maintain better elasticity. It is more green and environmentally friendly than bamboo charcoal polyester fiber and bamboo charcoal polypropylene fiber; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com