Sludge concentration method and filtering separation device thereof

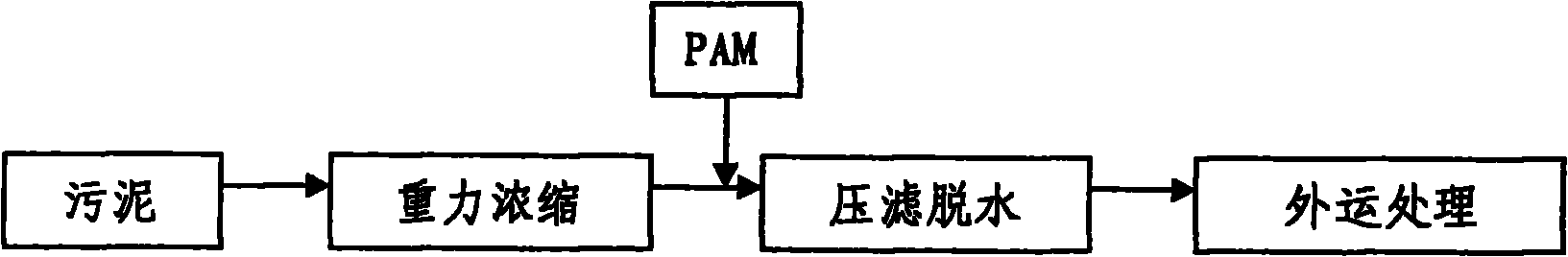

A filtration separation and sludge concentration technology, which is applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve the problems of high investment and operation costs, power consumption, high moisture content of concentrated sludge, etc., and achieve investment cost reduction and operation cost Low, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

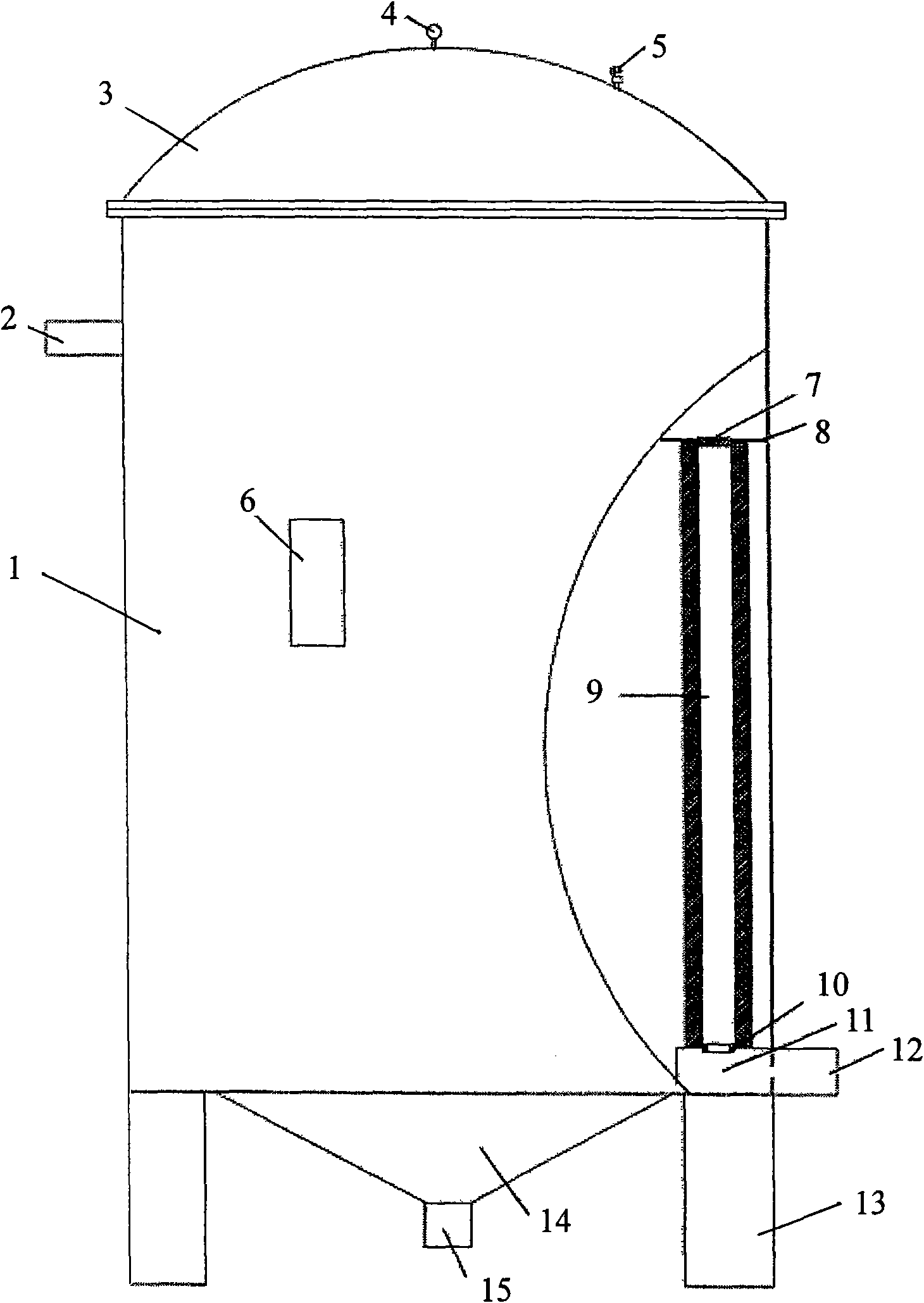

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the above-mentioned drawings.

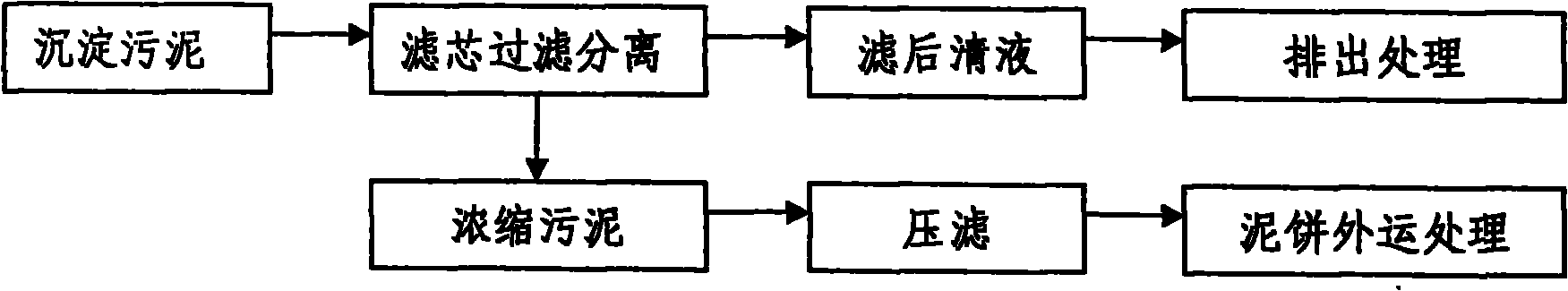

[0032] A sludge thickening method, the method combines figure 2 Include the following steps:

[0033] ① Filtration and separation: on the filtration and separation device, a tubular filter element made of filter element material is used to filter and separate gravity sedimentation sludge into concentrated sludge, and the filtered clear liquid is discharged for treatment;

[0034] ②Filter press treatment: The concentrated sludge separated by filtration is dehydrated by filter press on a filter press to form a mud cake for export.

[0035] In the sludge thickening process, in order to ensure the recovery of the filtering function of the tubular filter element made of ceramic or PP filter element material, the tubular filter element in the filtration separation device must be backwashed regularly. The air inlet and water inlet enter the tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com