Synthesis method of 2-chromium picolinate

A kind of technology of chromium picolinate and synthesis method, applied in the direction of organic chemistry and the like, can solve the problems of high price of potassium permanganate, low yield per pass, many side reactions, etc., and achieves good product quality, high reaction yield, synthesis Simple route effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

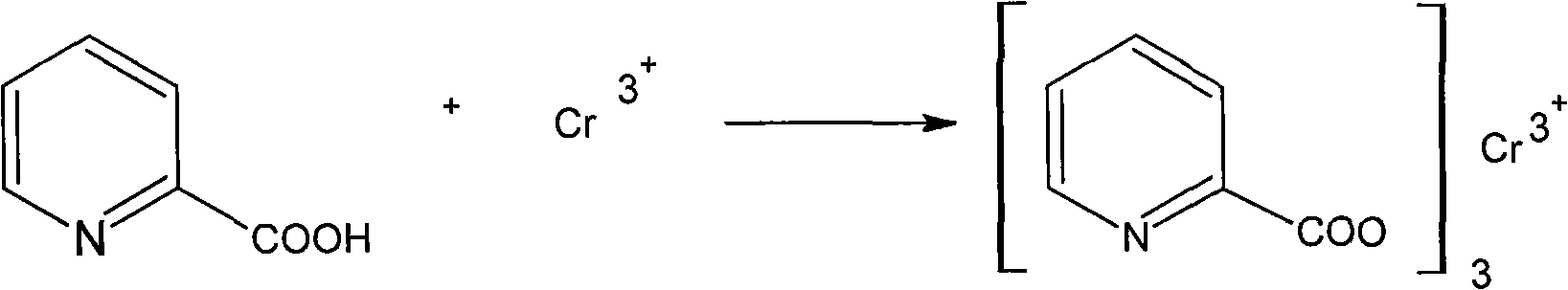

Image

Examples

Embodiment 1

[0018] (1) Synthetic aqueous solution of 2-pyridinecarboxylic acid:

[0019] In a 200ml three-necked flask, add 40g of deionized water, then add 20g of 2-cyanopyridine, start stirring, heat up to 70°C, add 26g of 30% sodium hydroxide in the flask, after the addition, Continue to raise the temperature, keep the reaction at 70°C for 6 hours, then cool to 30°C, add 30% hydrochloric acid, adjust the pH value of the reaction solution at 5.5, and maintain the temperature of the reaction solution at 50°C for use;

[0020] (2) Complexation reaction:

[0021] Add the prepared 20% chromium trichloride aqueous solution dropwise in the above 200ml three-necked flask, the amount of dropwise addition is 51.8g, after the addition, stir the complexation reaction for 1 hour, then cool to 20°C, and discharge, After draining, the filter cake was washed with 100 g of ion-free water for 4 times, then filtered and dried to obtain about 26.53 g of chromium 2-picolinate, with a yield of 99.0%. The q...

Embodiment 2

[0023] (1) Synthetic aqueous solution of 2-pyridinecarboxylic acid:

[0024] In a 200ml three-necked flask, add 40g of deionized water, then add 20g of 2-cyanopyridine, start stirring, heat up to 70°C, add 26g of 30% sodium hydroxide in the flask, after the addition, Continue to heat up, keep the temperature at 70°C for 6 hours, then cool to 30°C, add 30% hydrochloric acid, adjust the pH value of the reaction solution to 4.5, and maintain the temperature of the reaction solution at 50°C for use;

[0025] (2) Complexation reaction:

[0026] Add the prepared 20% chromium trichloride aqueous solution dropwise in the above 200ml three-necked flask, the amount of dropwise addition is 51.8g, after the addition, stir the complexation reaction for 1 hour, then cool to 20°C, and discharge, After draining, the filter cake was washed with 200g of ion-free water for 4 times, then filtered and dried to obtain about 26.20g of chromium 2-picolinate, with a yield of 97.8%. The quality index ...

Embodiment 3

[0028] (1) Synthetic aqueous solution of 2-pyridinecarboxylic acid:

[0029] In a 200ml three-necked flask, add 40g of deionized water, then add 20g of 2-cyanopyridine, start stirring, heat up to 50°C, add 30g of 30% sodium hydroxide in the flask, after the addition, Continue to heat up, keep the temperature at 60°C for 10 hours, then cool to 30°C, add 30% hydrochloric acid, adjust the pH value of the reaction solution to 5.5, and wait for the temperature of the reaction solution to drop to 45°C before use;

[0030] (2) Complexation reaction:

[0031] Add the prepared 20% chromium trichloride aqueous solution dropwise in the above 200ml three-necked flask, the amount of dropwise addition is 53.8g, and then stir the complexation reaction for 1 hour after adding, then cool to 20°C, and discharge, After draining, the filter cake was washed with 200 g of ion-free water for 4 times, then filtered and dried to obtain about 26.40 g of chromium 2-picolinate, with a yield of 98.5%. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com