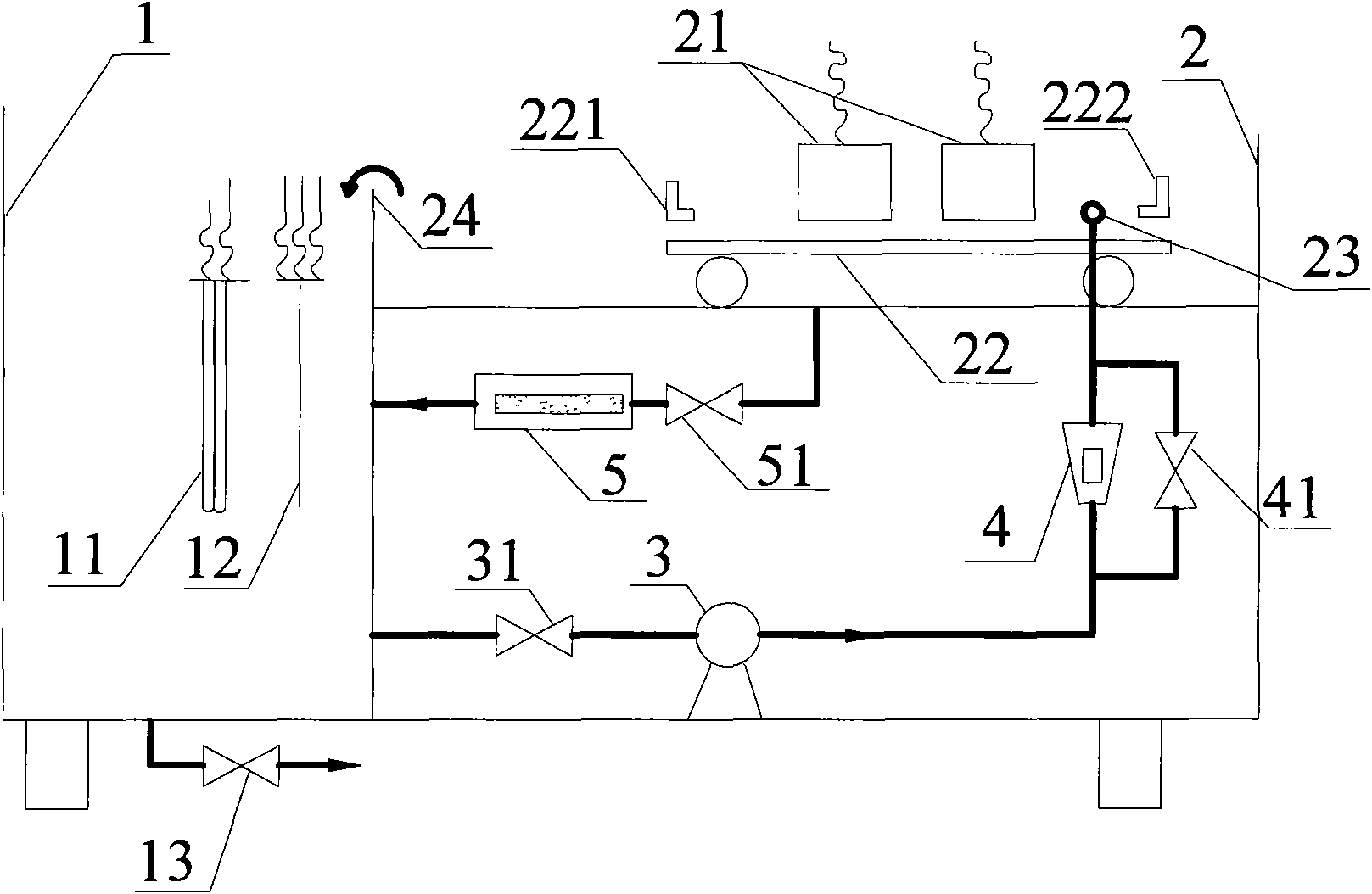

Electrolysis apparatus and electrolysis method used in aluminum substrate performance detection

An electrolysis device and electrolysis method technology are applied in the field of detection of electrolytic performance of aluminum substrates for printing, which can solve the problems of lagging performance detection methods, affecting the production process of aluminum substrates for printing, and inability to detect the electrolytic corrosion performance of aluminum substrates for printing in time. , to achieve the effect of improving lag and fast performance detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0030] The purpose of electrolytic sand treatment is to carry out AC electrolysis in the electrolytic corrosion medium. The principle is: under the action of current, when the aluminum substrate for printing is used as the cathode, the hydrogen ions in the electrolytic corrosion medium accept electrons on the aluminum plate to generate hydrogen gas and escape. 2H + +2e→H 2 ↑; Because it is alternating current, when the positive and negative electrodes are exchanged and the aluminum substrate for printing is used as the anode, the aluminum substrate releases electrons and generates aluminum ions that enter the electrolyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com