Oscillating damper

A shock absorber and outer cylinder technology, applied in the field of machinery, can solve the problems of difficult installation, inconvenient replacement and maintenance, and difficult manufacturing of external circulation oil pipes, and achieve easy stepless linear adjustment, improved convenience, and cost-effectiveness. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

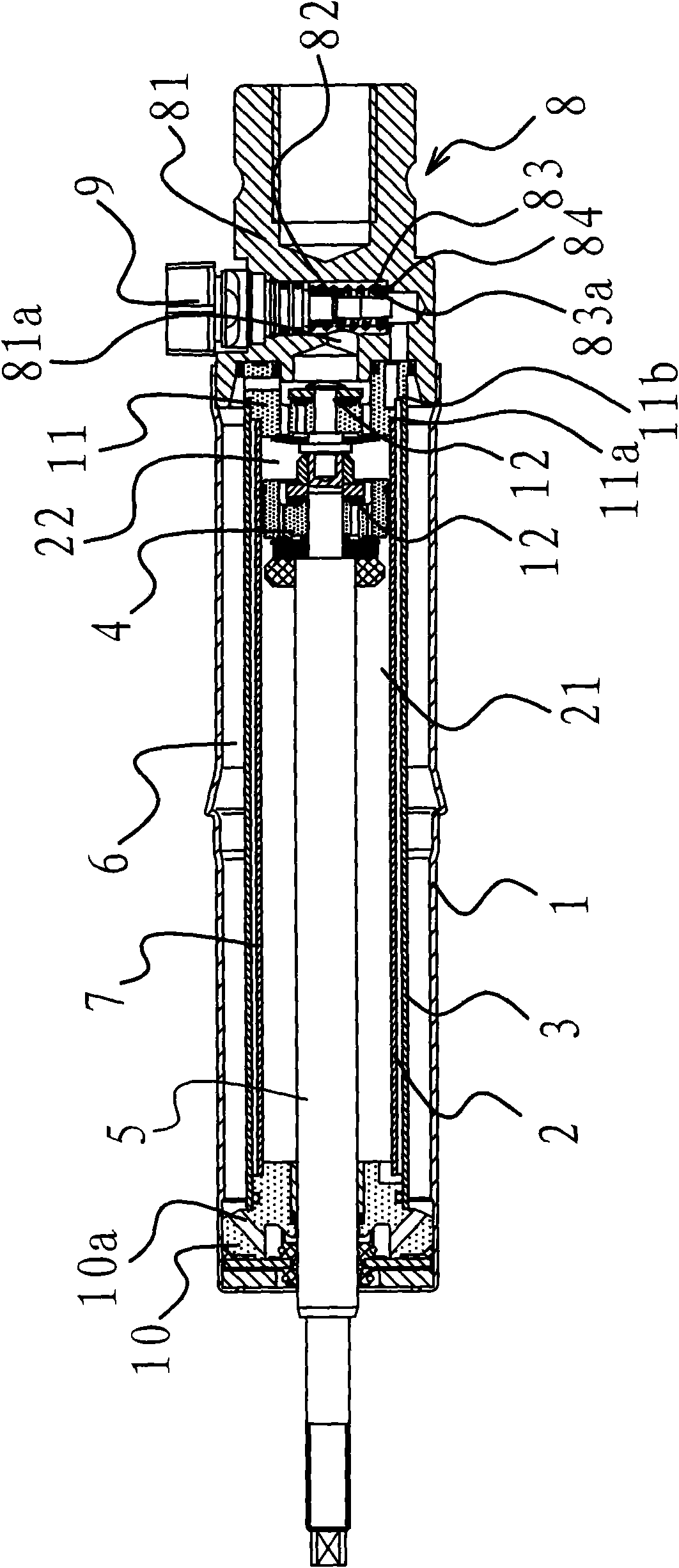

[0024] Such as figure 1 As shown, the shock absorber includes parts such as an outer cylinder 1, a cylinder 2, an intermediate cylinder 3, a piston 4, a piston rod 5, a regulating valve 8, and a guide 10.

[0025] The cylinder 2 is arranged in the outer cylinder 1, and the outer cylinder 1 is also provided with an intermediate cylinder 3 which is sleeved outside the cylinder 2. There is an annular cavity 6 between the outer cylinder 1 and the intermediate cylinder 3. In the middle There is an annular chamber 2 7 between the barrel body 3 and the cylinder barrel 2 . The cylinder 2 is provided with a piston 4 and a piston rod 5 fixedly connected with the piston 4 , the piston 4 divides the cylinder 2 into an upper chamber 21 and a lower chamber 22 , and the outer end of the piston rod 5 extends out of the outer cylinder 1 . A regulating valve 8 is provided at the bottom of the outer cylinder 1 . The piston rod 5 in this embodiment is thinner.

[0026] In this embodiment, the ...

Embodiment 2

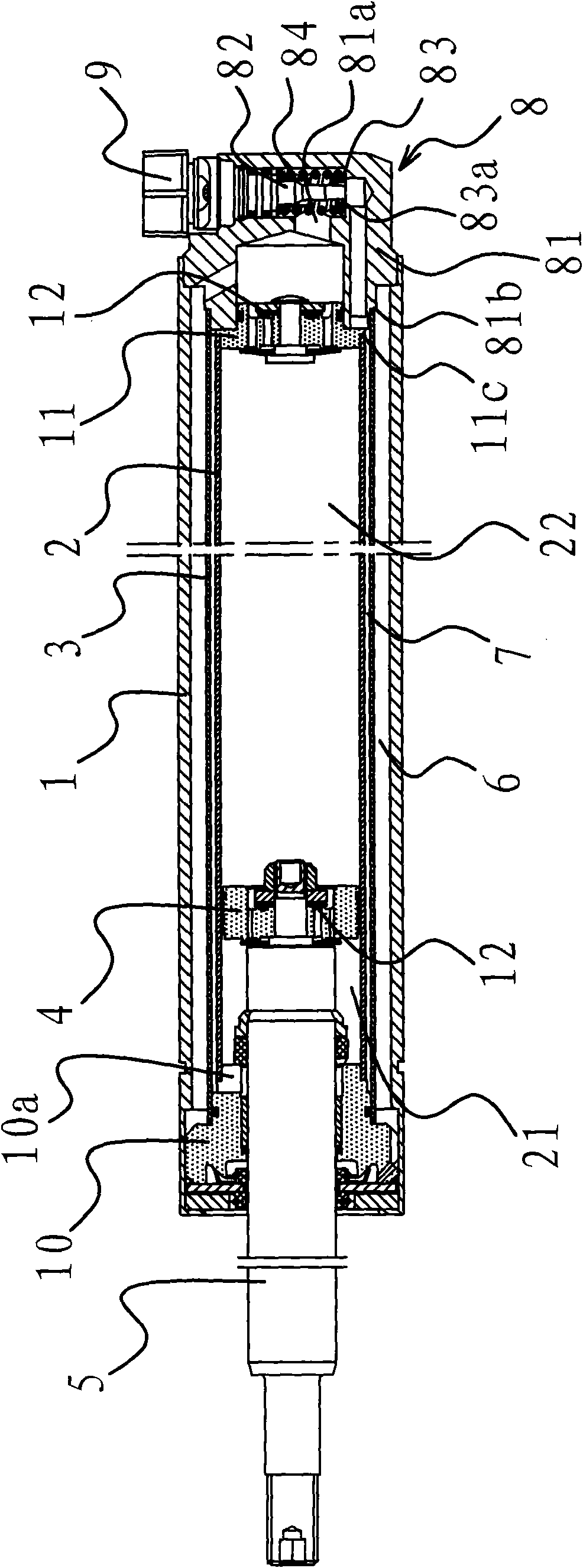

[0030] Such as figure 2 As shown, in this embodiment, the compression valve seat 11 is provided with an annular step 3 11c, the regulating valve 81 is provided with an annular step 4 81b, one end of the cylinder 2 is against the annular step 3 11c, and the middle cylinder One end of the body 3 leans against the annular step 4 81b. The piston rod 5 in this embodiment is relatively thick. The rest are similar to those in Example 1, and will not be described in detail herein.

Embodiment 3

[0032] In this embodiment, the first annular chamber 6 is an oil circulation chamber, and the second annular chamber 7 is an oil storage chamber. Since the positions of the oil storage chamber and the oil circulation chamber in this implementation are different from those in Embodiment 1 and Embodiment 2, the structure of the rest of the shock absorber, such as guides, regulating valves, and compression valves, should also be adjusted accordingly. The rest are similar to Embodiment 1 or Embodiment 2, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com