Dispatching method applied to multi-enterable complex manufacturing system

A technology for manufacturing systems and scheduling methods, applied in the general control system, control/regulation system, adaptive control, etc., to achieve the effects of improving calculation efficiency, simple concept, and fast convergence speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

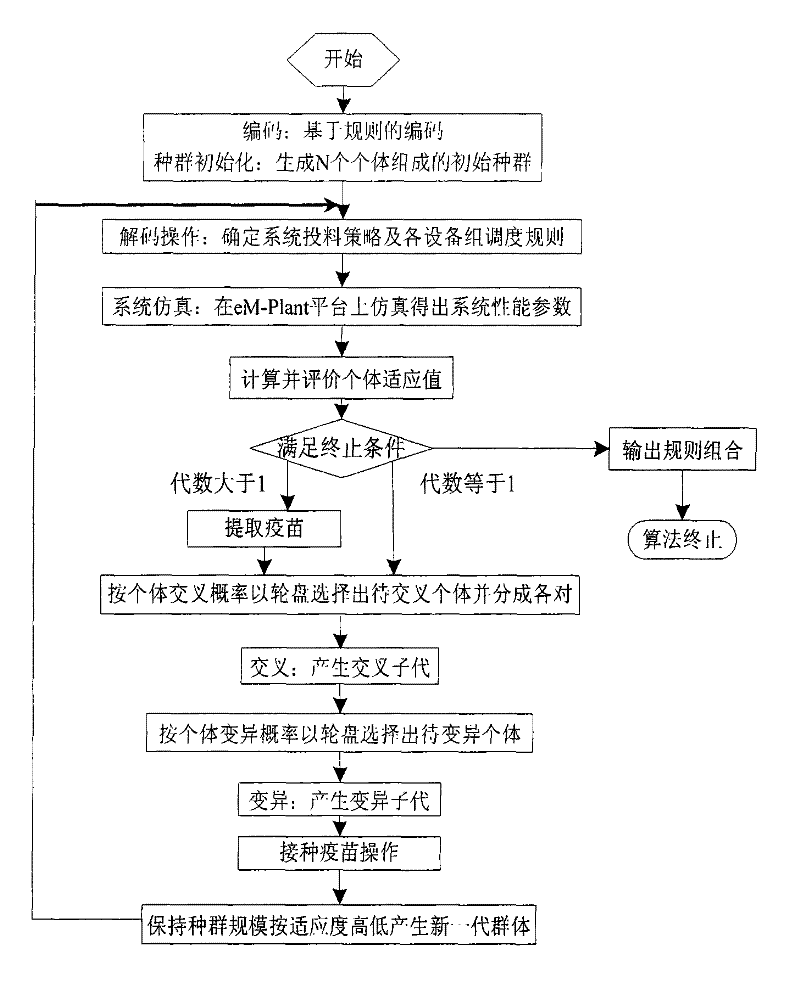

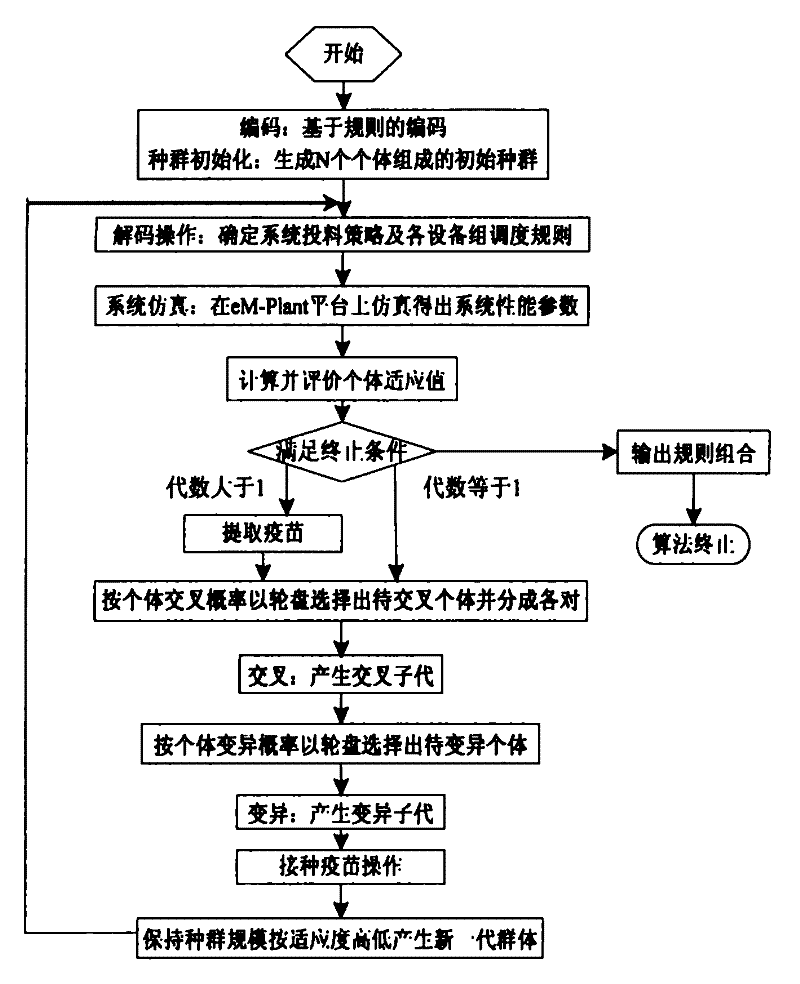

Method used

Image

Examples

Embodiment Construction

[0041] Provide following embodiment in conjunction with content of the present invention:

[0042] Taking Minifab, a simplified model of a semiconductor production line, as an example for analysis, Minifab produces 3 types of workpieces, consisting of 3 equipment groups and 5 equipment, including 2 batch processing equipment and 3 single-piece processing equipment. The process flow of the workpiece A total of six processes are included.

[0043] (1) Chromosomal coding

[0044] According to the characteristics of semiconductor production line scheduling, the immune algorithm coding adopts the coding method based on scheduling rules, combined with the feeding strategy. Chromosomes in this paper have four types of genes: g l , g m , g d and g b , respectively represent the feeding rules, workpiece selection equipment rules, single-chip processing rules and multi-batch processing rules. where g l =(a, b), a, b represent feeding rules UNIF and CONWIP respectively; g m =(c, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com