Compact type self-resonant diaphragm filter

A self-resonant, compact technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problems of difficult to reduce the center frequency of the passband, difficult to realize narrow-band filters, etc., and achieve volume reduction and good out-of-band suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

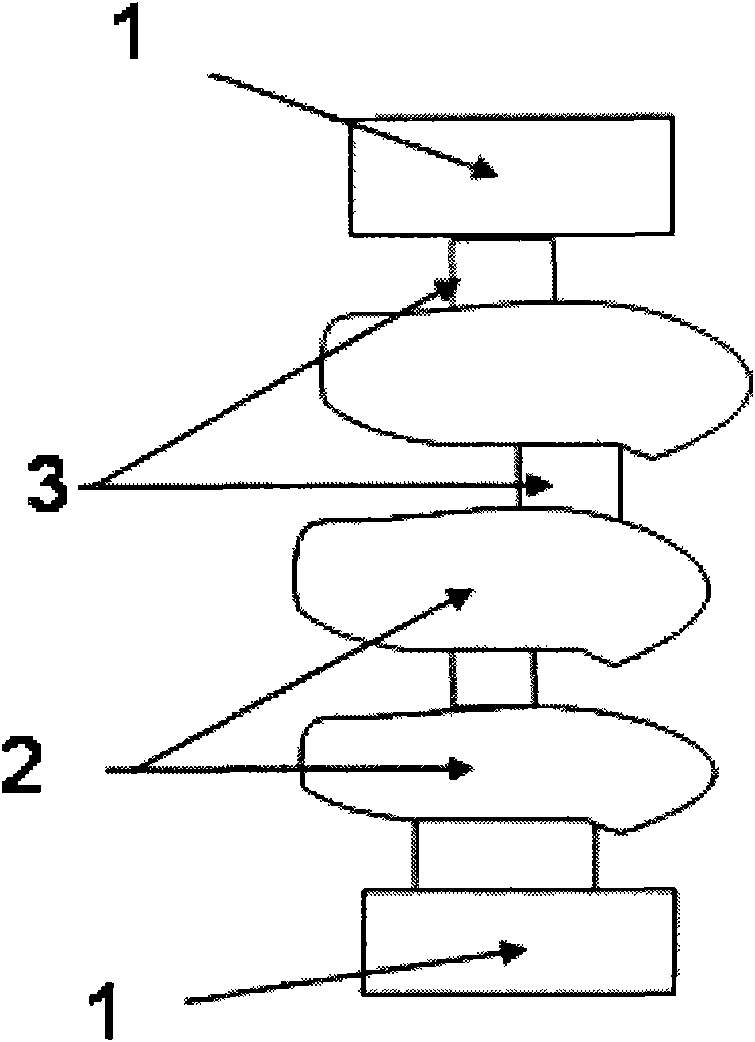

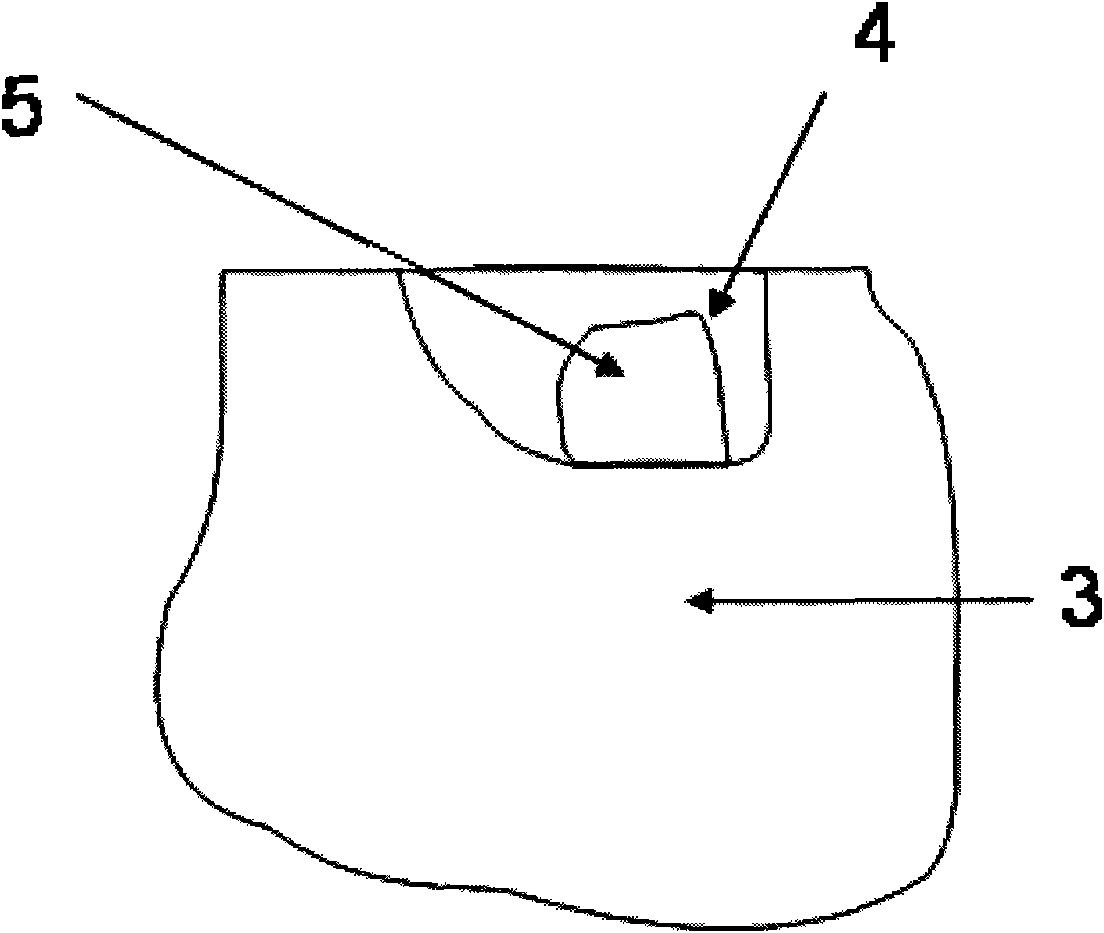

[0029] Such as figure 1 , figure 2 As shown, the compact self-resonant diaphragm filter is composed of an input-output structure 1, a resonant cavity 2 and a self-resonant diaphragm 3, and a coupling hole 4 communicating with the resonant cavity 2 is provided on the self-resonant diaphragm 3; the coupling hole 4 is provided with at least one metal boss 5 inside, and the bottom of the metal boss 5 is connected with the bottom of the coupling hole 4 . The upper surface of the coupling hole 4 is located in the same plane as the upper surface of the resonant cavity 2, and its lower surface is not in the same plane as the lower surface of the resonant cavity 2; At least one pair of side faces on the right side is not in the same plane; the length of the resonant cavity 2 along the filter axis is 0.1 mm smaller than one-fifth of the waveguide wavelength determined by the width of the resonant cavity at the highest frequency of the passband of the filter.

[0030] The resonant cav...

Embodiment 2

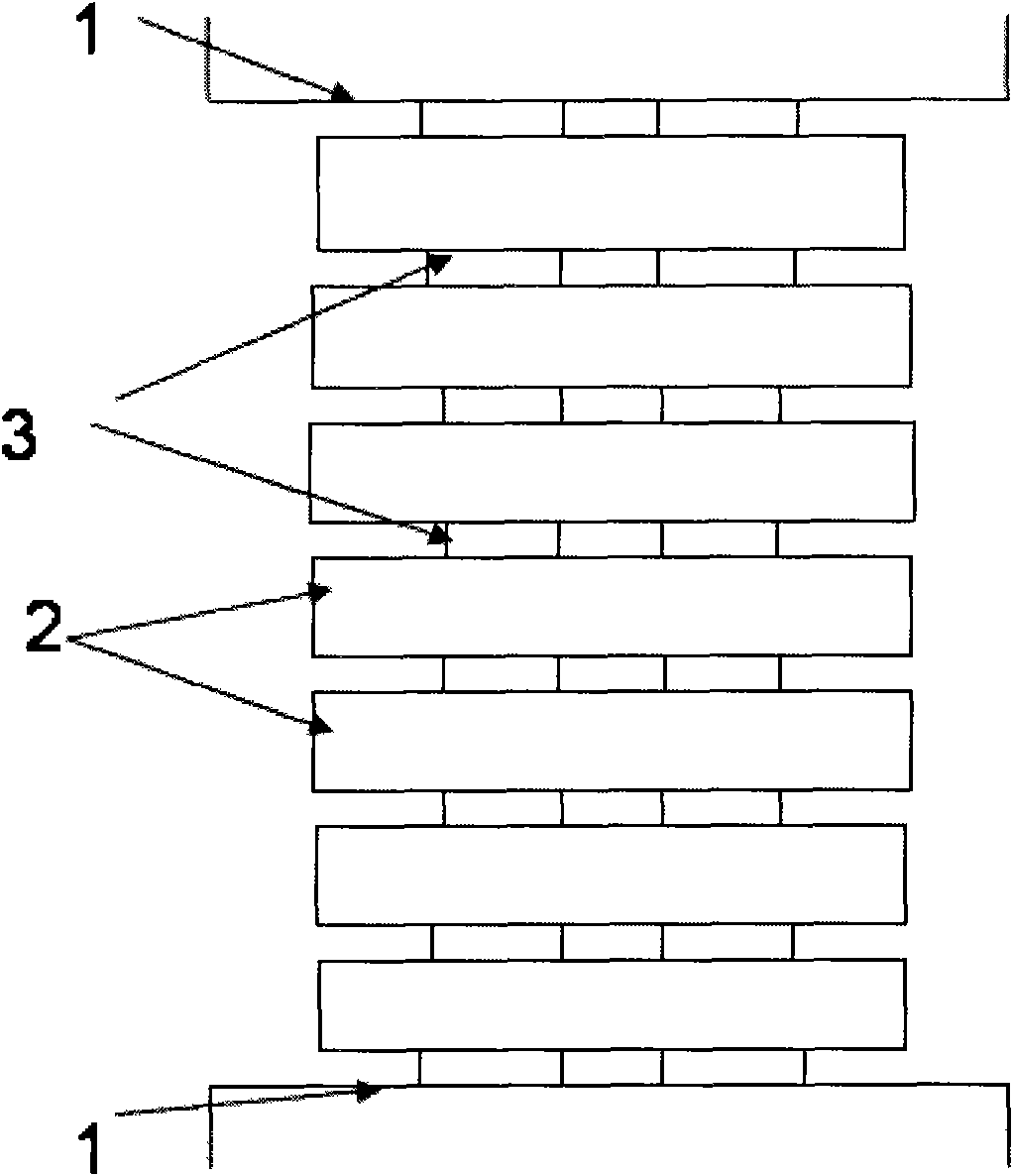

[0032] The difference between this embodiment and Embodiment 1 is that a self-resonant diaphragm 3 is provided between two adjacent resonant cavities 2 in this embodiment, and a self-resonant membrane is also provided between the resonant cavity 2 and the input-output structure 1. Sheet 3, and resonant cavity 2, self-resonant diaphragm 3, coupling hole 4 and metal boss 5 are all rectangular.

[0033] Based on embodiment 2, the tables of three different structural parameters are enumerated below, and correspondingly obtained as attached Figure 5 , attached Figure 6 , attached Figure 7 The scattering matrix curve is shown.

[0034] variable

size

(mm)

variable description

variable

size

(mm)

variable description

a0

22.9

Input and output port width

h1=h8

9.7

The height of the 1st and 8th coupling holes

b0

10.2

Input and output port height

h2=h7

9.8

The heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com