Process for stabilized zirconium triethanolamine complex and uses in oil field applications

一种三乙醇胺、络合物的技术,应用在钻孔的组合物、化学仪器和方法、周期表第4/14族元素的化合物等方向,能够解决络合物昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] method

[0044] Preparation of base gel

[0045] Fill the Waring mixer jar with 1 liter of distilled water. To this was added 2 g of a 50% aqueous solution of tetramethylammonium chloride clay stabilizer. Stirring was started and 3.6 g of carboxymethylhydroxypropyl guar (CMHPG) was sprayed into the vortex of the stirred solution. The pH of the resulting slurry was adjusted to 6 with sodium diacetate and stirring was continued for 30 minutes. The pH was then adjusted to 10.3 with 10% sodium hydroxide solution. Stirring was stopped and the gel was allowed to stand for 30 minutes or more before use.

[0046] Viscosity determination of zirconate-crosslinked substrate gels

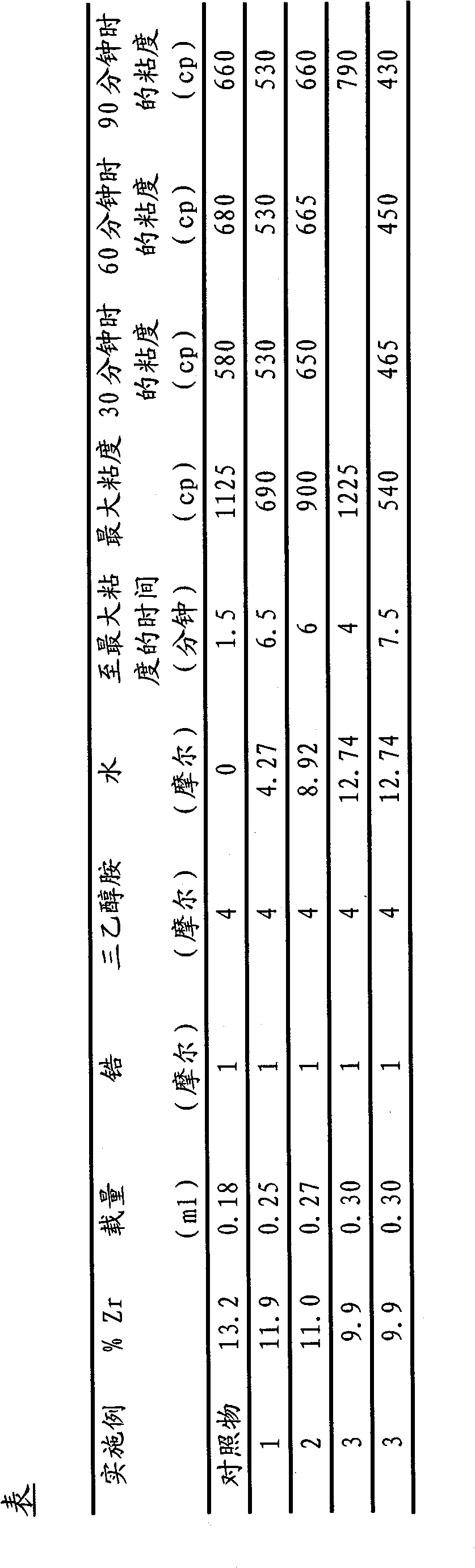

[0047] To a 250 mL sample of vigorously stirred base gel in a Waring mixer jar was added 0.00032 moles of zirconium (0.2-1.0 mL, depending on the percentage of zirconium in the solution of crosslinker - hereinafter referred to as standard packing density). Stir continuously for about 15-180 seco...

Embodiment 1

[0054] In the 250mL flask, add 180g tetrakis (triethanolamine) zirconium ( TEAZ organozirconate available from E.I.E.I. du Pont de Nemours and Company, Wilmington, DE). Stirring was started and 20 g of water was slowly added. The mixture was heated to 80° C. and kept at this temperature for 4 hours to obtain 200 g of a pale yellow solution containing 11.9% Zr. The product is stable for at least six months.

Embodiment 2

[0056] In 250mL flask, add 167g tetrakis (triethanolamine) zirconium ( TEAZ organic zirconate). Stirring was started and 33 g of water were slowly added. The mixture was heated to 80° C. and kept at this temperature for 4 hours to obtain 200 g of a pale yellow solution containing 11.0% Zr. The product is stable for at least six months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com