Optical engine

An optical engine, engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of uneven movement, restricted, restricted observation, etc., achieve good self-lubricating effect, reduce weight, and avoid adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

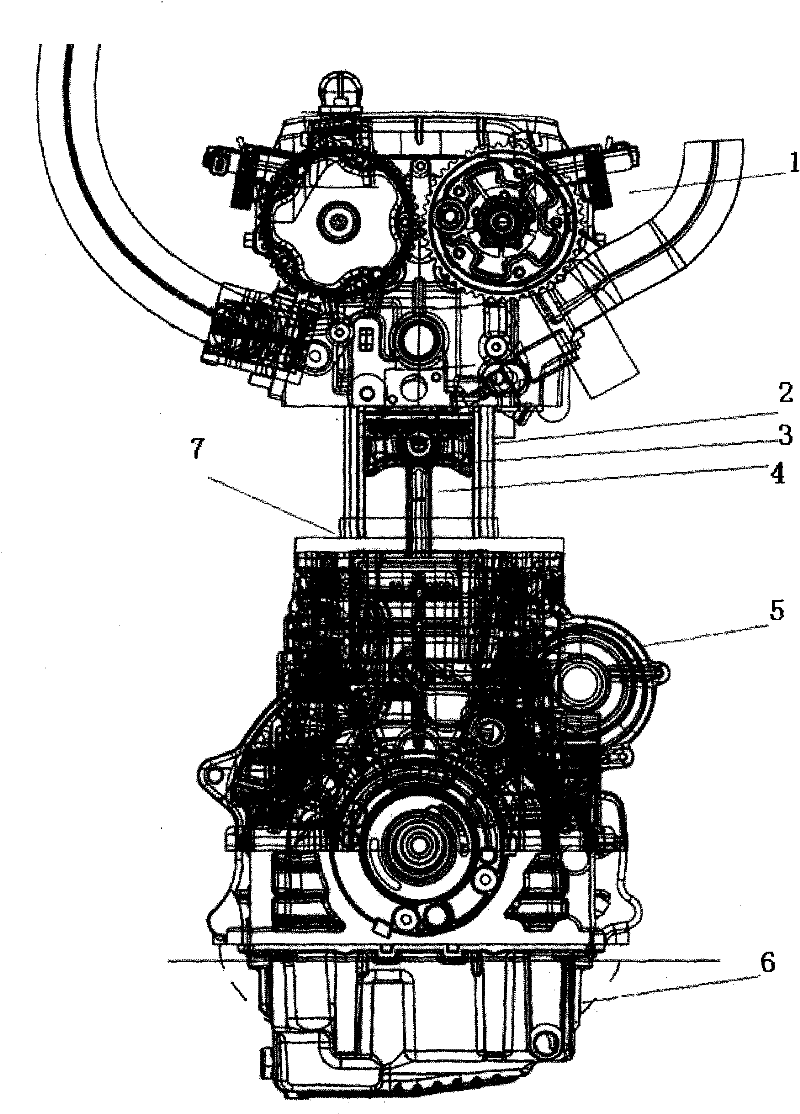

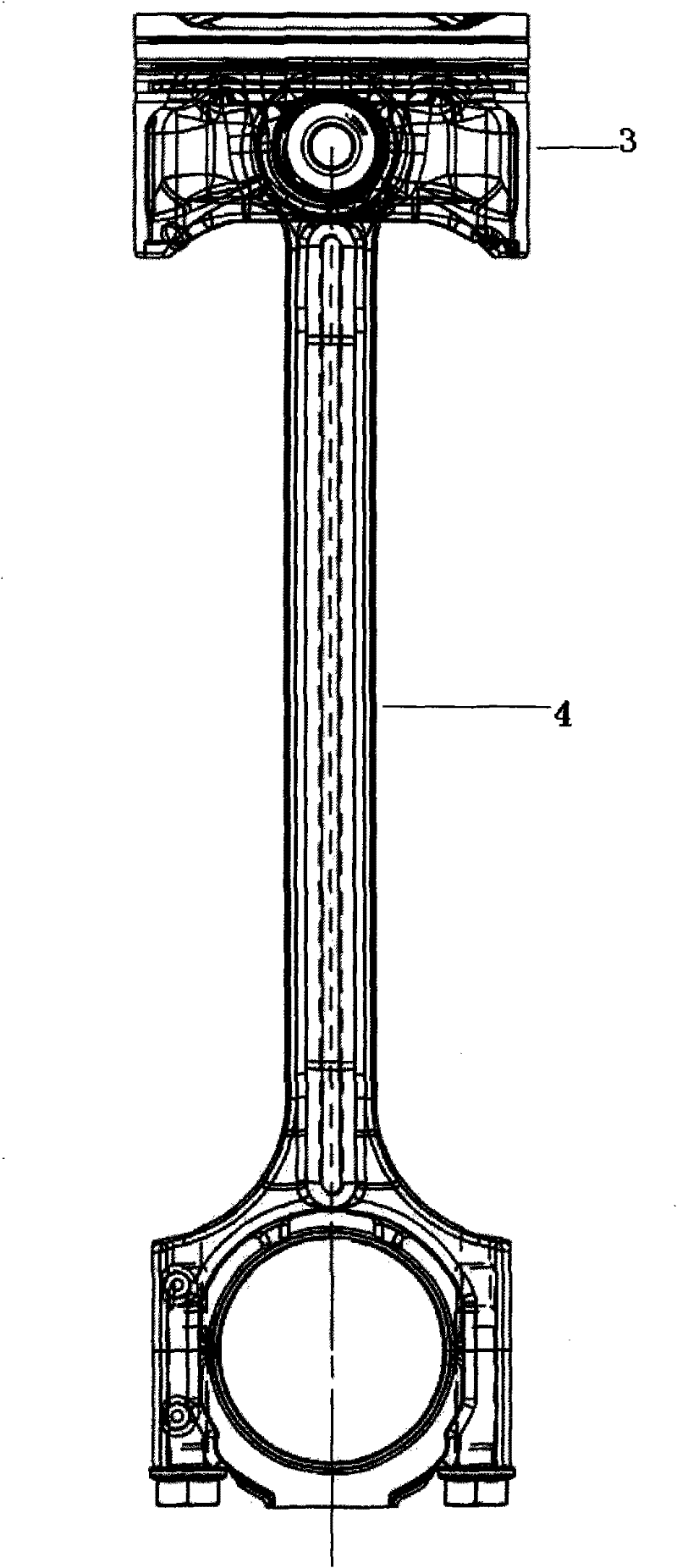

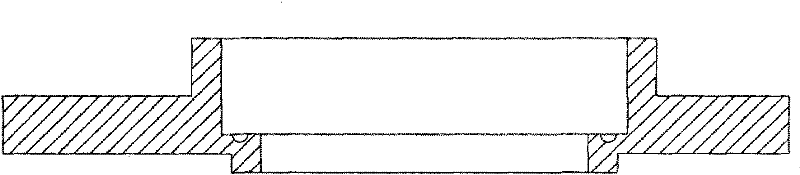

[0032] Such as figure 1 As shown, the optical engine is mainly modified on the multi-cylinder prototype. During the transformation process on the multi-cylinder prototype, the original engine cylinder head system, cylinder block, crankcase system, piston and other parts are kept unchanged. A transparent quartz glass cylinder liner is added between the cylinder block and the cylinder head, and the connection is fixed with bolts. The maximum operating speed of the modified optical engine is 2000r / min. It is mainly used to study the flow field in the engine cylinder, the formation of spray and mixed gas, etc. No research on in-cylinder combustion. The prototype piston is used to keep the shape of the top surface of the piston unchanged, so that the compression ratio of the optical engine c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com