Method and device for measuring three-dimensional topography of surface of moving object

A technology of moving objects and measurement methods, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve high precision, eliminate measurement errors, and prevent distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

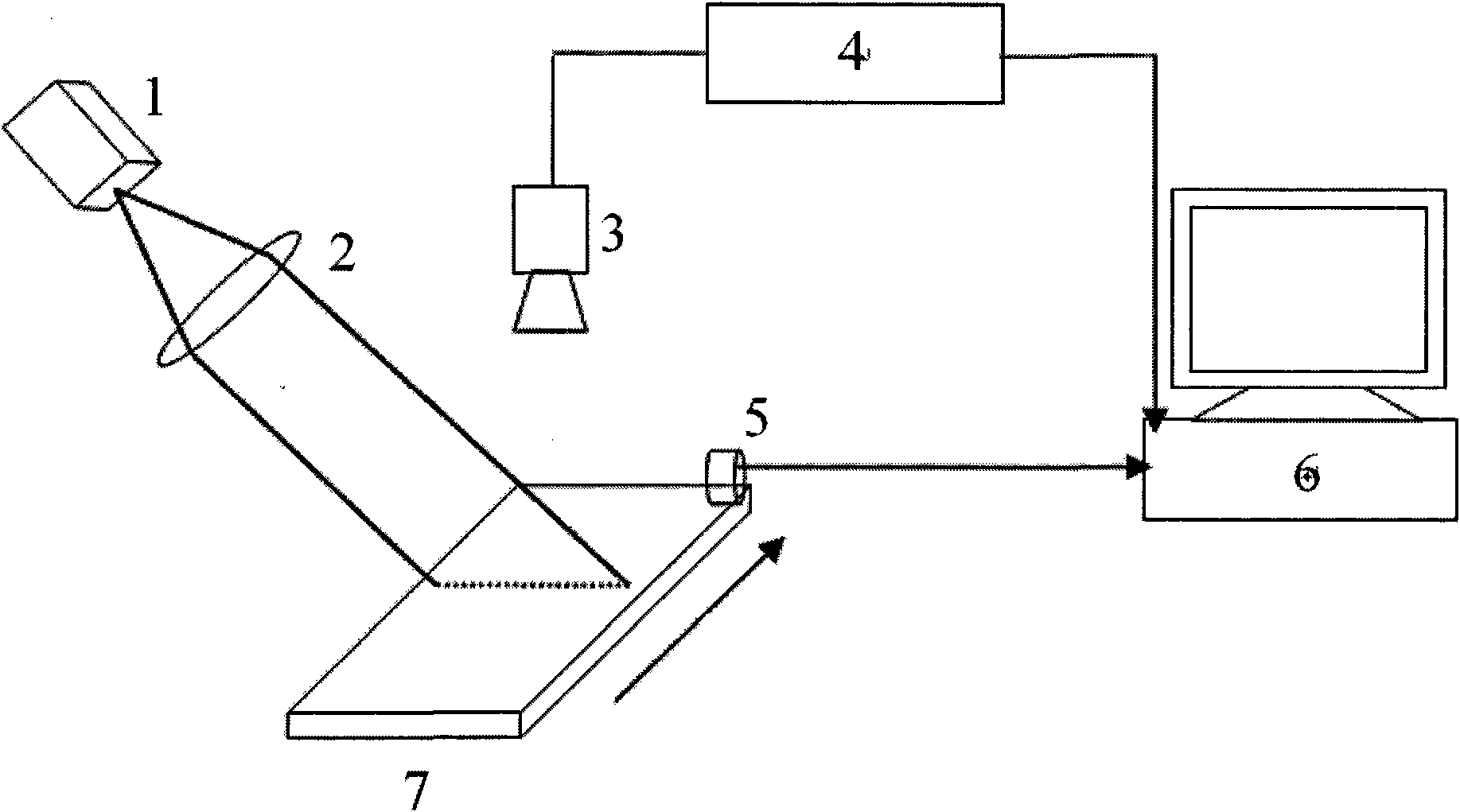

[0012] figure 1 It is a structural schematic diagram of an embodiment of a three-dimensional measuring device for the surface topography of a moving object in the present invention. The measuring device is composed of an optical projector 1, a lens 2, a line scan camera 3, an image acquisition card 4, a rotational speed encoder 5 and a computer 6.

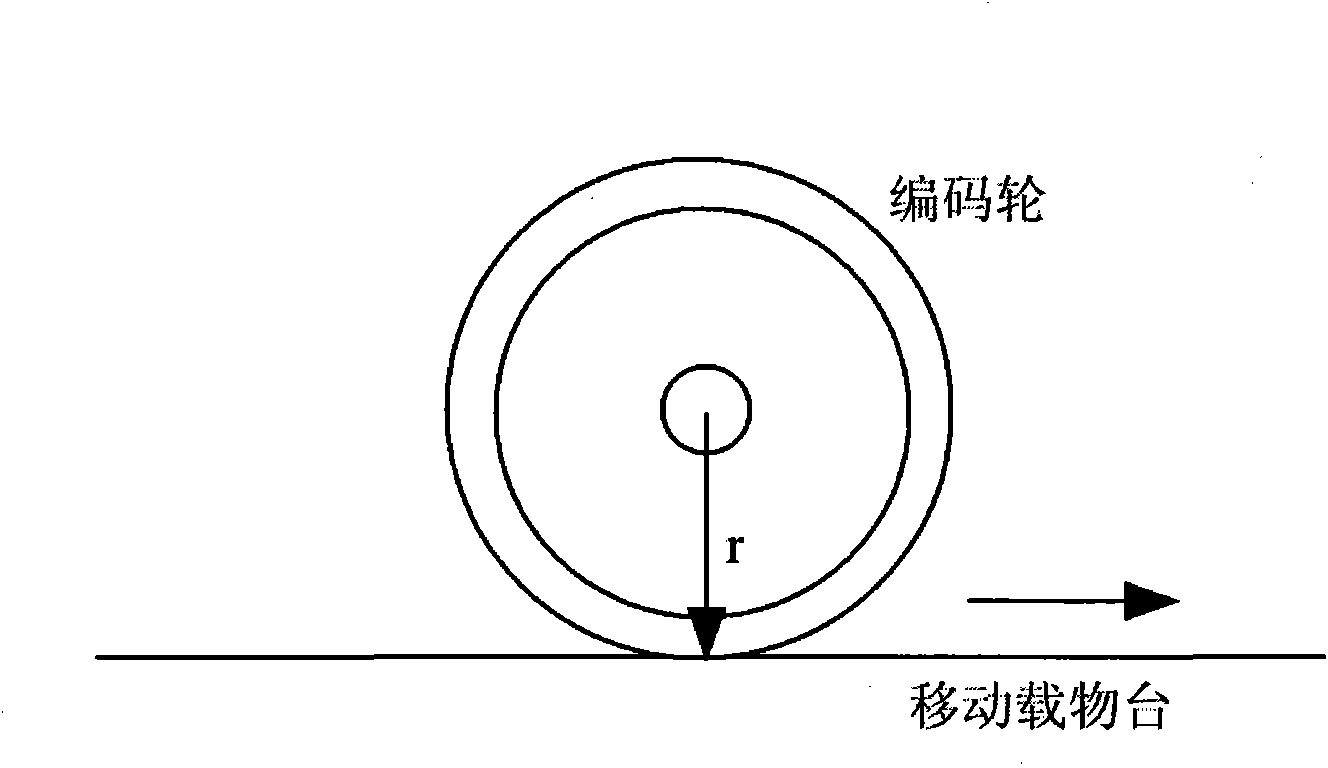

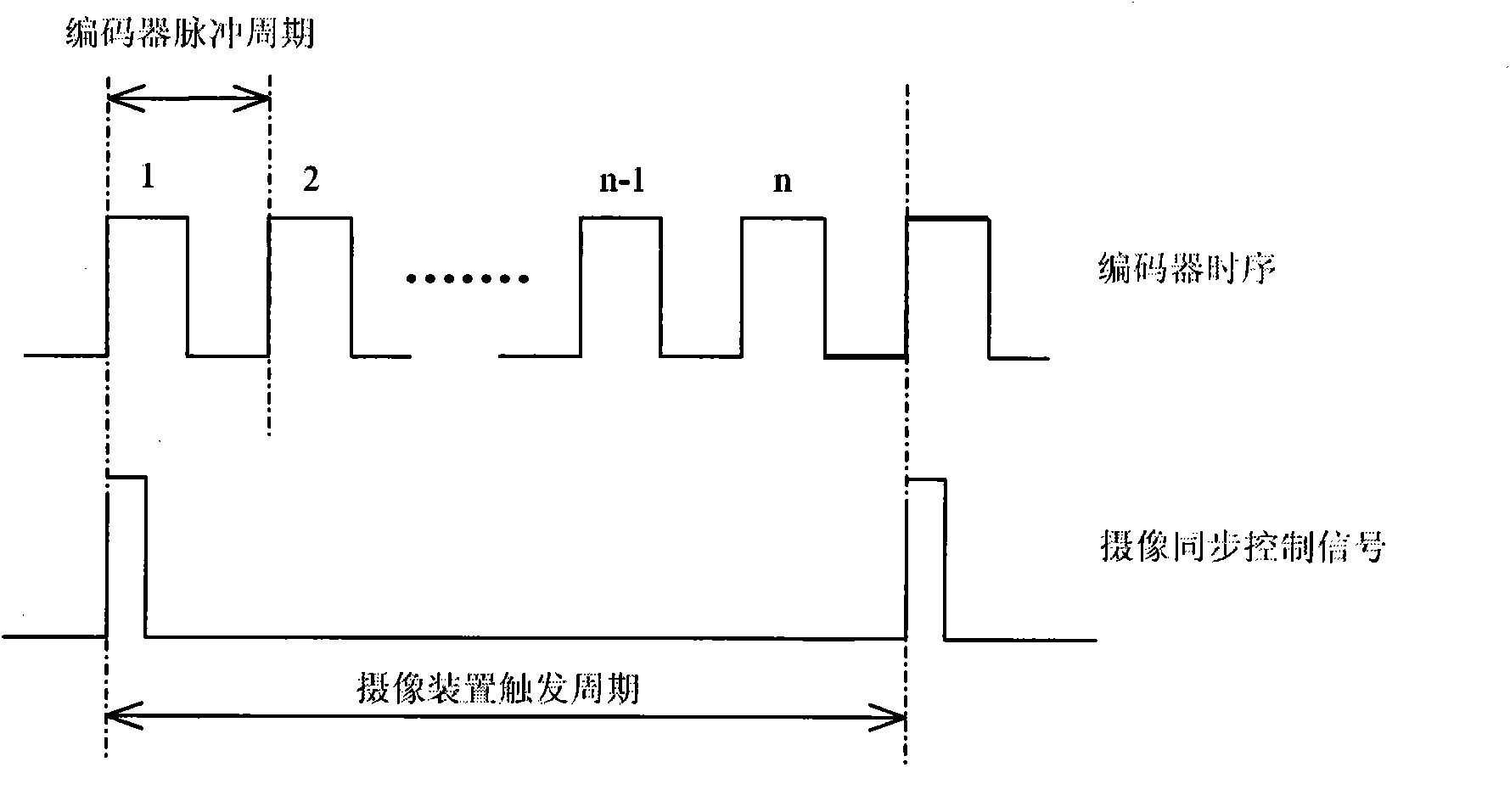

[0013] The digital cosine light emitted by the projector 1 enters the lens 2, and the parallel digital cosine grating emerges from the lens 2 to reach the surface of the object 7 to be measured, and the projection angle is 30 degrees. The line scan CCD camera 3 is used to take pictures of deformed fringe patterns, and its optical axis is perpendicular to the surface of the object 7 to be measured. When the object moves relative to the measuring system, a rolling wheel is installed on the shaft of the encoder 5, and the rotational speed of the rolling wheel is guaranteed to be the same as the moving speed of the object through frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com