Method for measuring material nonlinearity based on phase object single-pulse reflection

A phase object and reflection measurement technology, applied in the field of nonlinear properties, can solve the problems of low transmittance, increase the difficulty of measurement, and inapplicability of optical nonlinearity, and achieve the effect of high sensitivity and simple optical path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

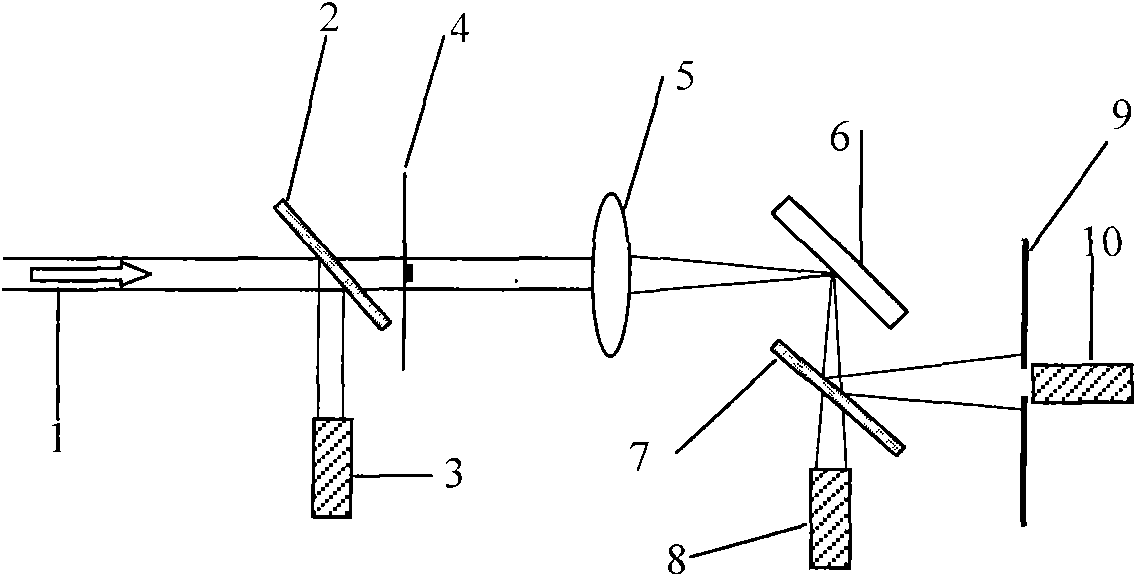

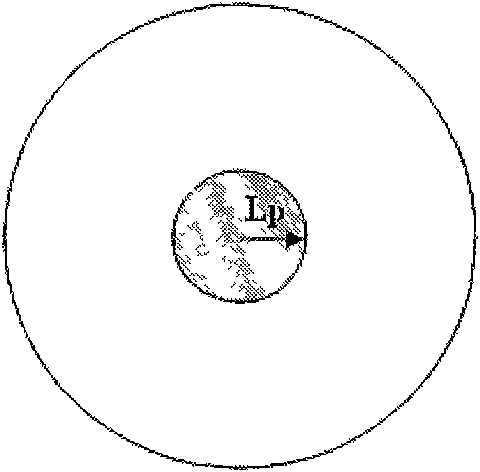

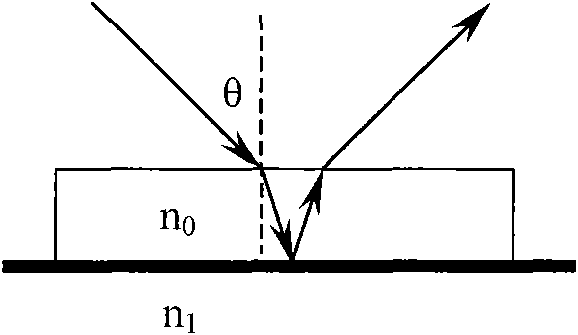

[0025] See attached Figure 1~3 As shown, a method for measuring material nonlinearity based on single-pulse reflection of a phase object, the incident laser light 1 is divided into two beams by the first beam splitter 2, one beam is the monitoring light, which is recorded by the first detector 3, and the other beam After passing through the phase object 4, it is focused on the sample 6 by the lens 5, and the pulsed light reflected by the surface of the sample 6 is divided into two paths by the second beam splitter 7, one path is directly recorded by the second detector 8, and the other path passes through the A small hole diaphragm 9 whose center coincides with the optical axis enters the third detector 10;

[0026] The specific detection steps are:

[0027] (1) The sample 6 to be tested is placed near the lens 5, and the second detector 8 and the third detector 10 are used to measure the energy of the aperture and the aperture diaphragm 9 respectively, while the first detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com