Power frequency withstand voltage and partial discharge test terminal structure of medium-low voltage crosslinked cable

A terminal structure and cable work technology, applied in the direction of measuring electricity, measuring electrical variables, and testing dielectric strength, etc., can solve the problems of unsuitable, enlarged, and increased terminal installation difficulty of the test terminal, and achieve the improvement of partial discharge level and installation. Convenience and the effect of improving installation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

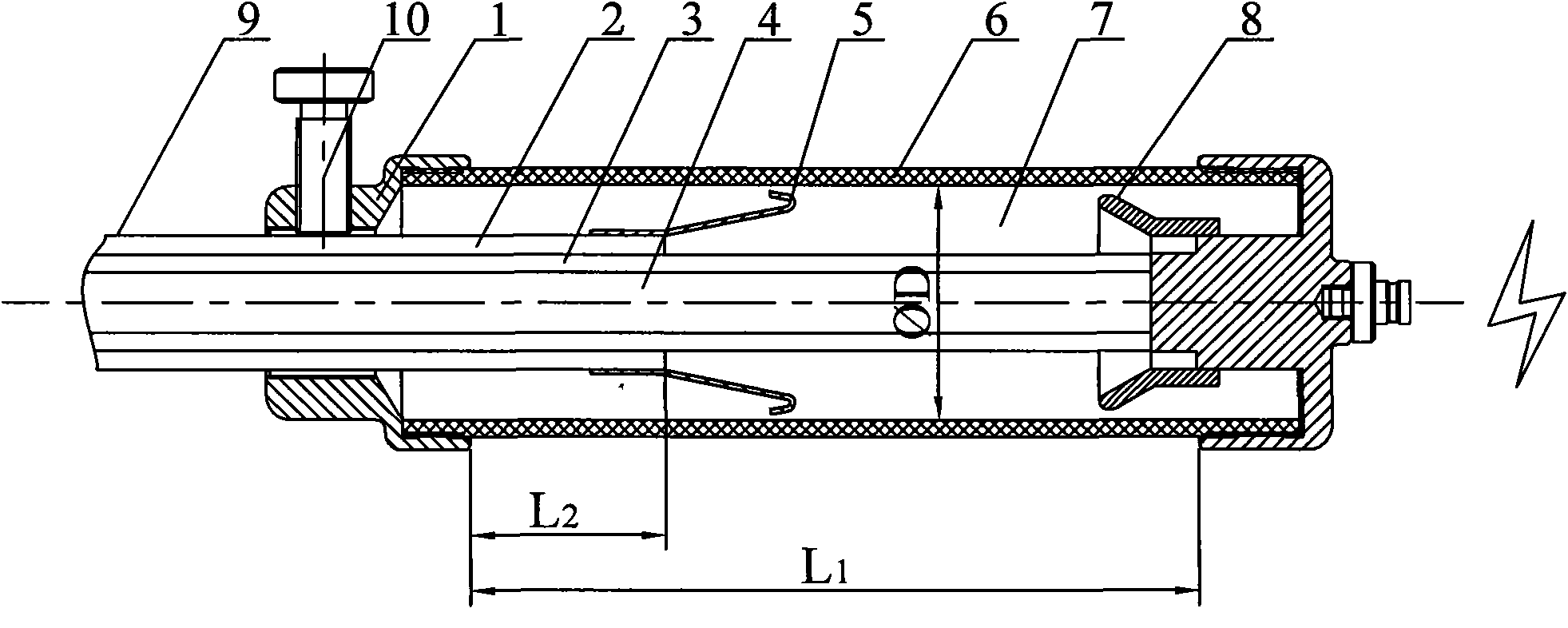

[0012] According to attached figure 1 The insulation shielding at both ends of the cable 9 is stripped to a certain length, and a metal stress cone 5 is set on the cable insulation shielding 2 at both ends of the cable 9, and then inserted into a plexiglass casing 6 equipped with a fluorocarbon compound 7 . The insulating medium adopts non-combustible fluorocarbons, which have very good insulating properties. The boiling point is 50-60 ° C. It is safe, reliable, cost-effective, and environmentally friendly. As long as the cable insulation and metal stress cones are completely immersed in the liquid, the localization of the cable can be carried out. Discharge, power frequency withstand voltage test.

Embodiment 2

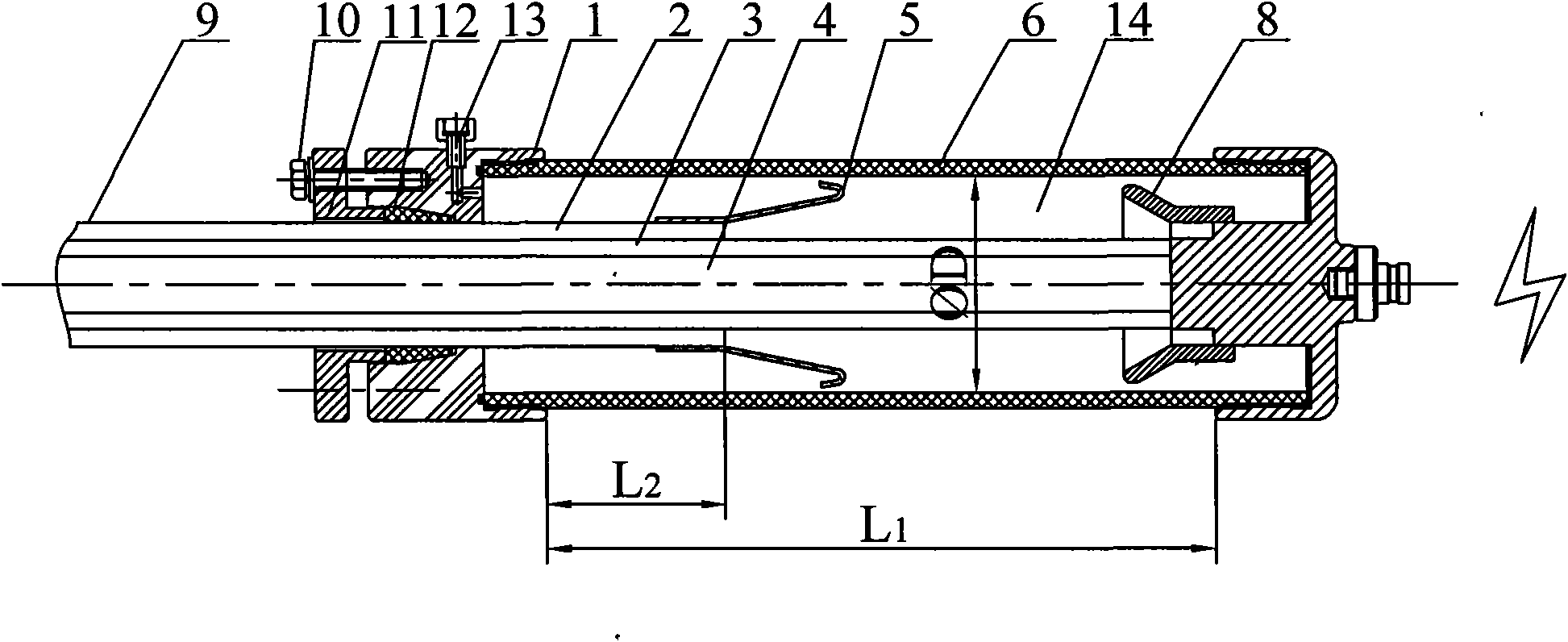

[0014] Sulfur hexafluoride 14 is used as the insulating medium, and a tapered sealing ring 12, a cover plate 11 and a hexagon head bolt 10 are added outside the metal cover 1 at the left end of the plexiglass sleeve 6, and the tapered sealing ring strengthens the gap between the metal cover and the outer diameter of the cable Sealing solves the short-term sealing problem at the left end, and the partial discharge and power frequency withstand voltage test of the cable can be carried out.

[0015] The present invention replaces the rubber prefabricated stress cone with the metal stress cone 5, the inner diameter of the metal stress cone is larger than the outer diameter of the cable insulation shield, and is fixed on the cable insulation shield 2, the cable insulation shield can be processed by the installation process of the Freon test terminal, and the installation convenience can be improved. continue.

[0016] According to the withstand voltage level and partial discharge r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com