Capacitor external expander

A technology for expanders and capacitors, applied in capacitors, electrical components, etc., to achieve the effects of good vacuum performance, convenient operation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

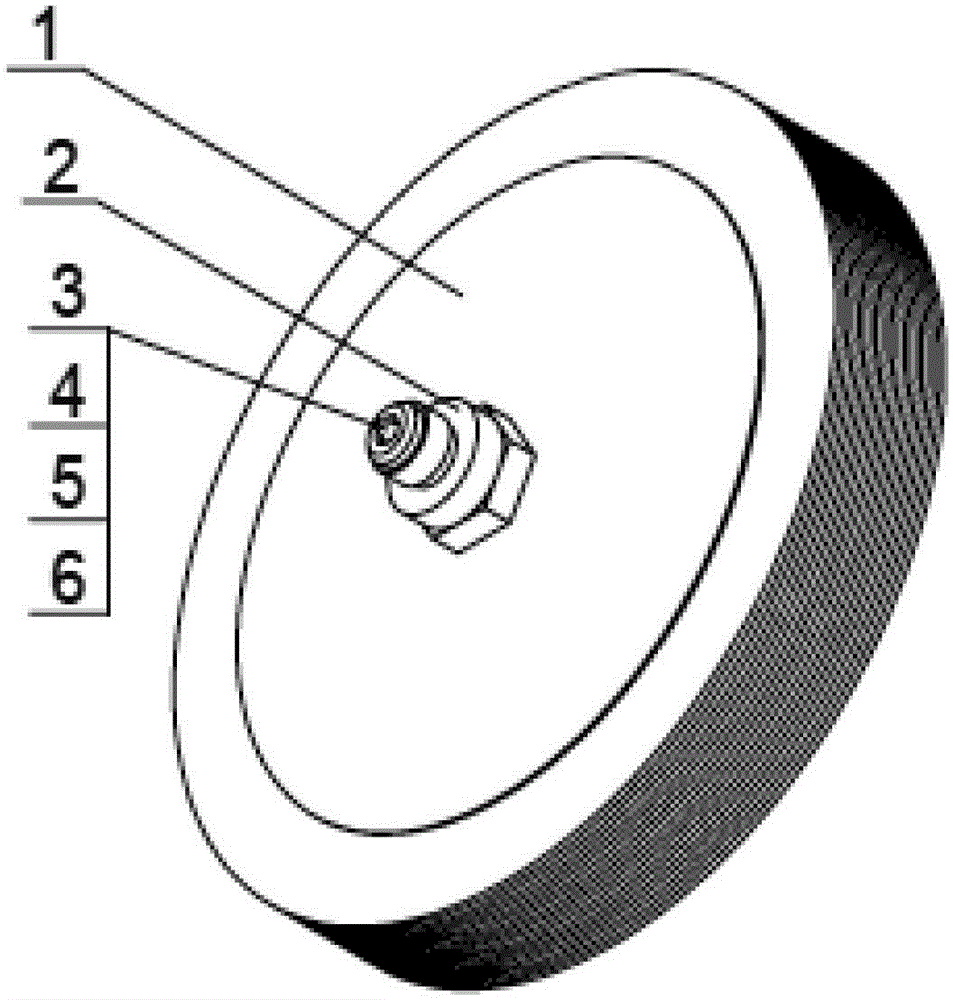

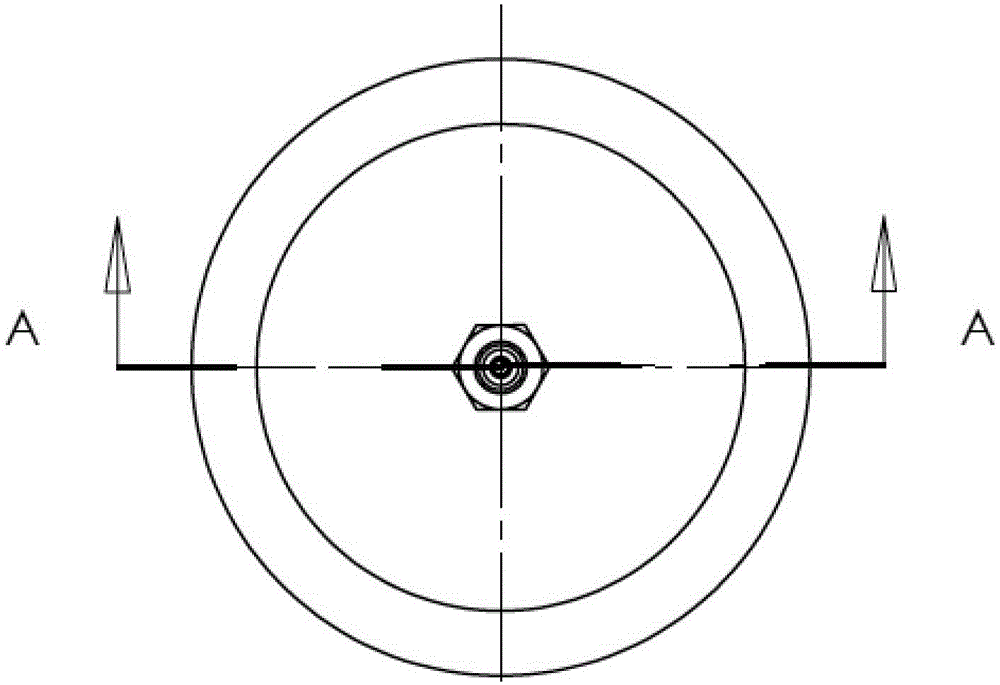

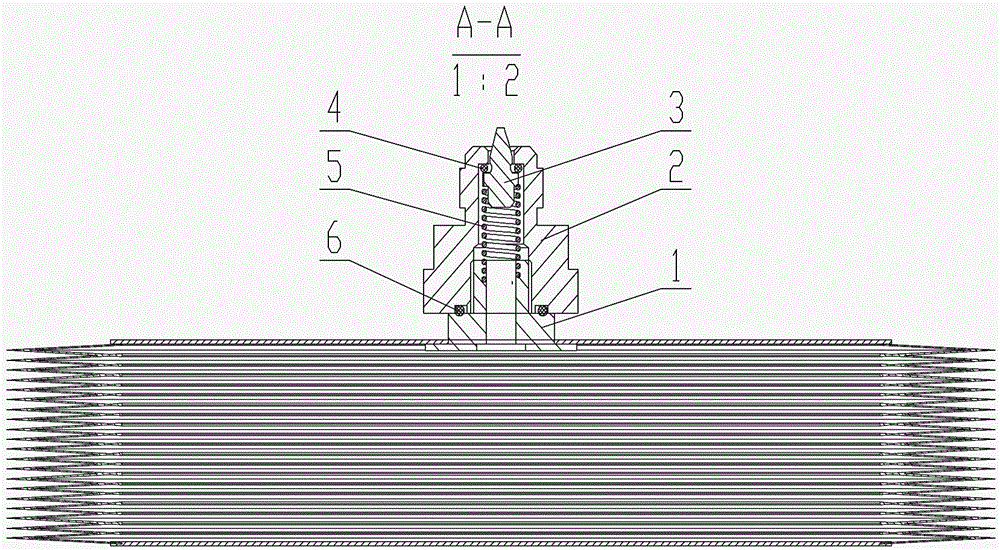

[0011] A capacitor external expander, such as figure 1 , figure 2 and image 3 As shown, it consists of expander body 1, connecting nut 2, oil drain valve 3, oil drain valve sealing ring 4, oil drain valve connecting spring 5 and expander sealing ring 6, wherein the expander body 1 and connecting nut 2 connection, an oil discharge valve 3 is provided on the expander body 1, an oil discharge valve connection spring 5 is provided on the oil discharge valve 3, and an oil discharge valve sealing ring 4 is provided between the connection nut 2 and the oil discharge valve 3 , An expander sealing ring 6 is provided between the expander body 1 and the connecting nut 2 . The compensation method and structure of the external expander are quite different from conventional expanders. The external expander adopts an internal oil-filled type, and the expander body is filled with oil in a vacuum state, and is tightly and sealed with connecting nuts and other components. Finally, it beco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com