Cold contraction intermediate joint and preparation method thereof

A technology of intermediate joints and intermediate layers, which is applied in the direction of cable joints, chemical instruments and methods, and other household appliances, and can solve the problems of high production costs of cold-shrinkable intermediate joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

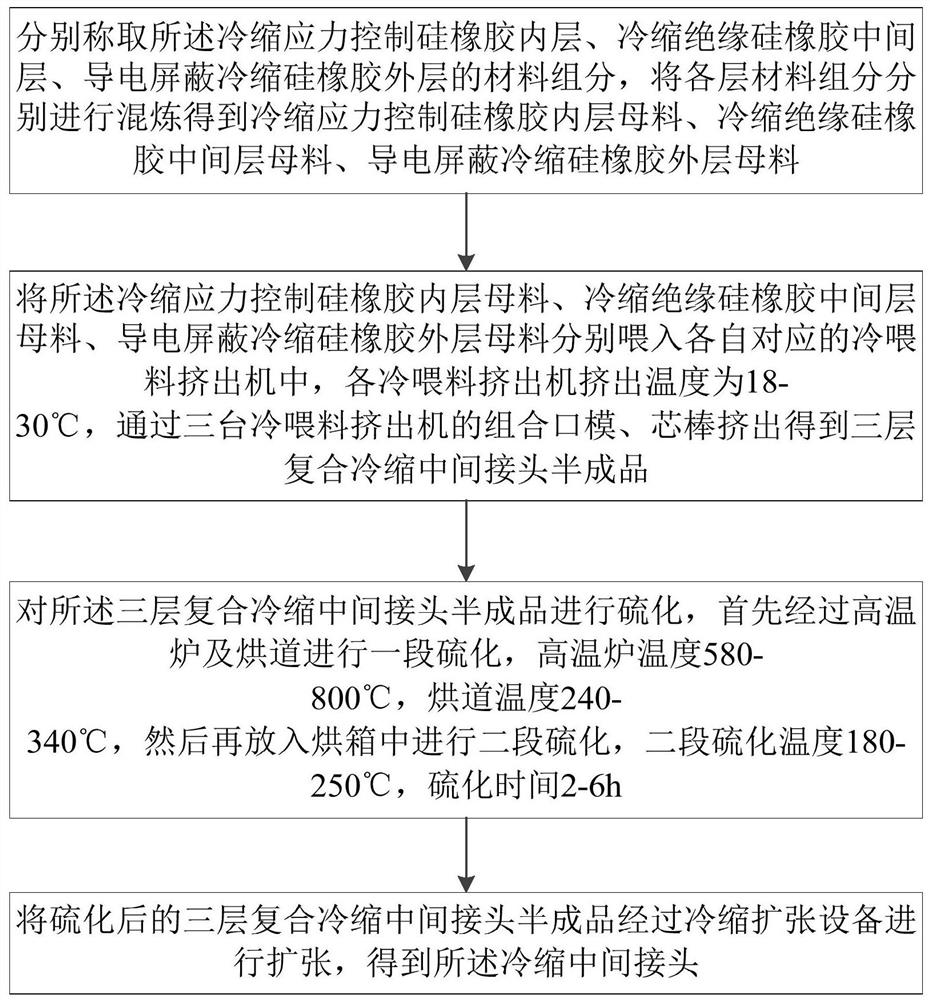

[0049] The present invention also proposes a method for preparing a cold-shrinkable intermediate joint. The cold-shrinkable intermediate joint includes an inner layer of cold-shrinkable stress-controlling silicone rubber, an intermediate layer of cold-shrinkable insulating silicone rubber, and an outer layer of conductive shielding cold-shrinkable silicone rubber. Please refer to figure 1 , the preparation method comprises:

[0050] Weigh the material components of the cold shrinkage stress control silicone rubber inner layer, the cold shrinkage insulating silicone rubber middle layer, and the conductive shielding cold shrinkable silicone rubber outer layer, and mix the material components of each layer separately to obtain the cold shrinkage stress control Silicone rubber inner layer masterbatch, cold shrink insulating silicone rubber middle layer masterbatch, conductive shielding cold shrinkable silicone rubber outer layer masterbatch;

[0051] The cold-shrinkage stress cont...

Embodiment 1

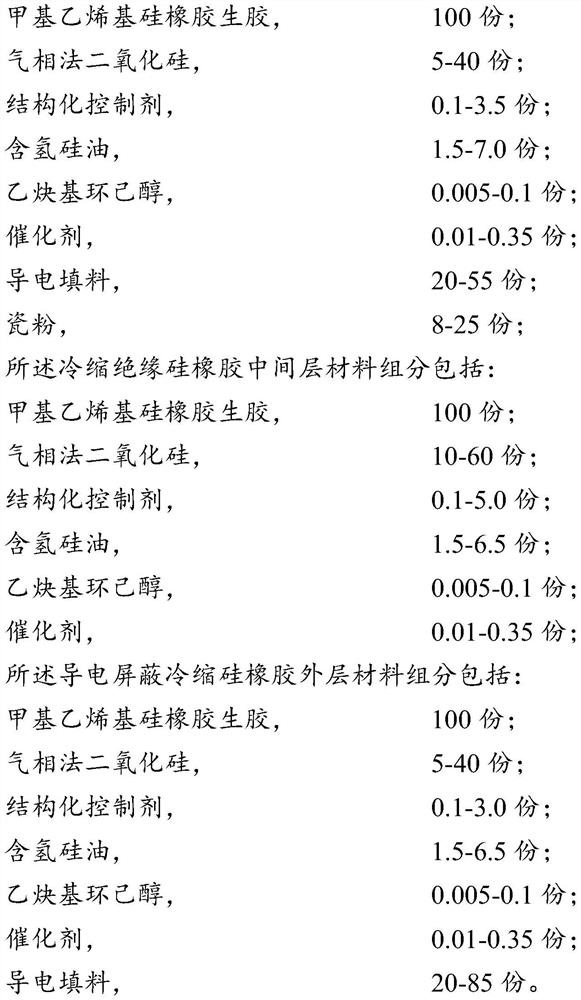

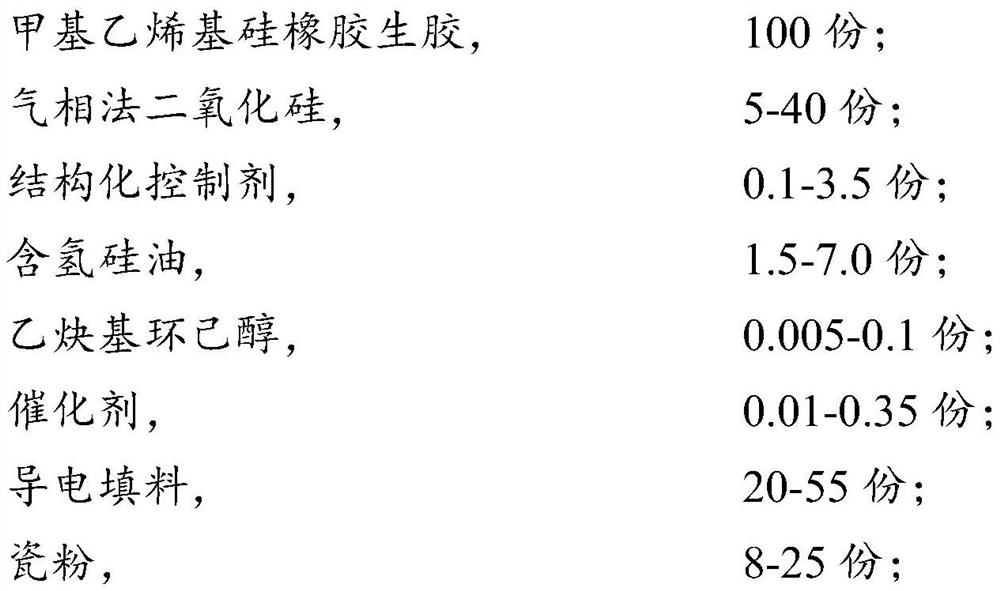

[0060] The cold-shrinkage stress control silicone rubber inner layer material components of the cold-shrinkable intermediate joint of Example 1 include: 100 parts of methyl vinyl silicone rubber raw rubber, 20 parts of fumed silica, 3 parts of hydroxy silicone oil, 40 parts of conductive carbon black, 25 parts of barium titanate, 2.0 parts of hydrogen-containing silicone oil, 0.006 parts of ethynyl cyclohexanol, and 0.02 parts of platinum catalyst.

[0061] The material components of the cold-shrinkable insulating silicone rubber intermediate layer of the cold-shrinkable intermediate joint in Example 1 include by weight: 100 parts of methyl vinyl silicone rubber raw rubber, 30 parts of fumed silica, hexamethyldisilazide 5.0 parts of alkanes, 2.0 parts of hydrogen-containing silicone oil, 0.006 parts of ethynyl cyclohexanol, and 0.03 parts of platinum catalyst.

[0062] The conductive shielding cold-shrinkable silicone rubber outer layer material components of the cold-shrinkab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com