Primordium control method during pleurotus eryngiu factory production.

A technology of production process and control method, applied in horticultural methods, botany equipment and methods, gardening tools/equipment, etc., can solve problems such as bacterial pollution, achieve high commodity value, reduce enterprise labor costs and management costs, and provide excellent quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

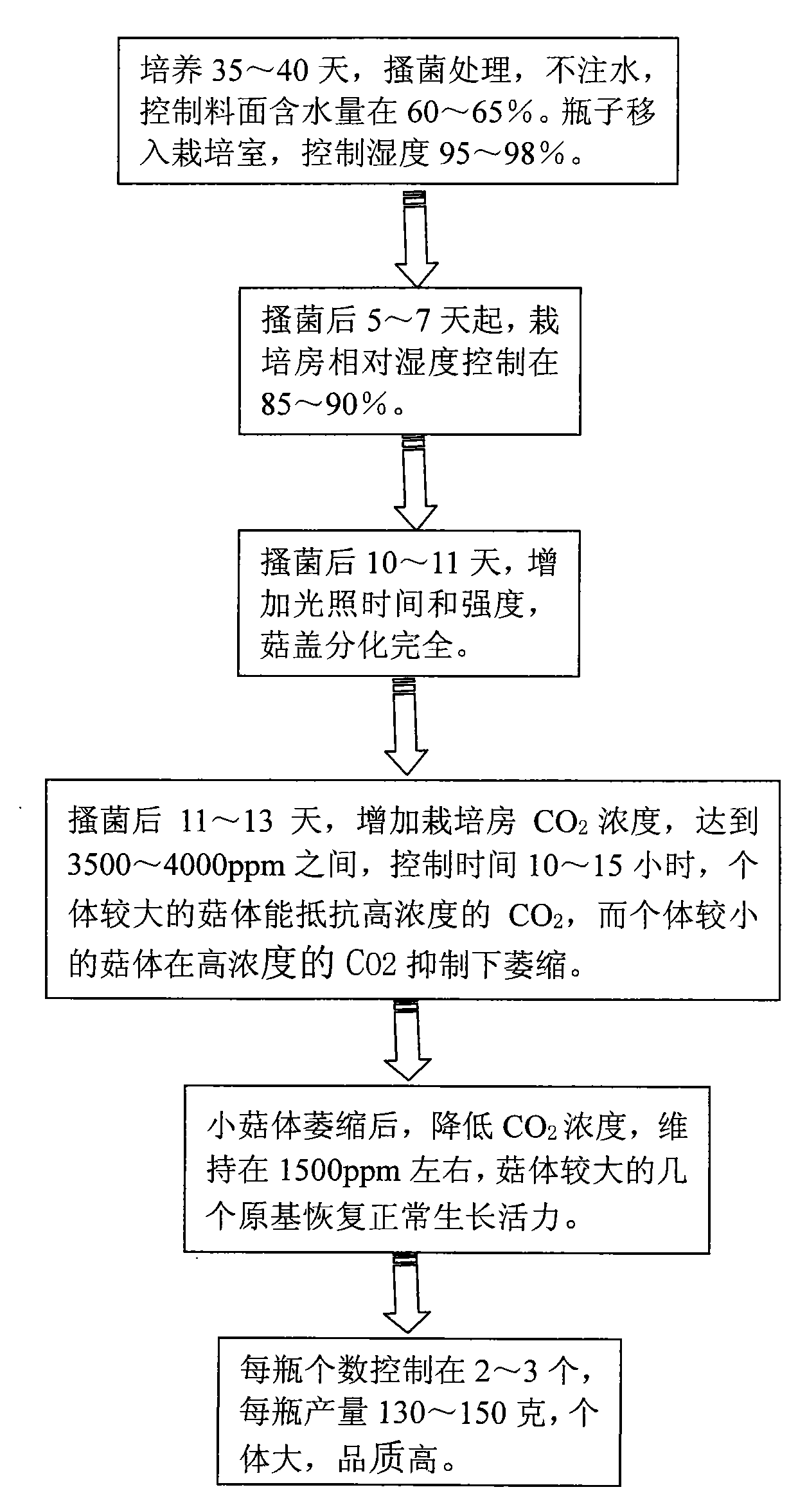

Method used

Image

Examples

Embodiment 1

[0012] 1. Raw material mixing

[0013] The raw materials required for cultivation are sawdust, corn cob powder, rice bran, bran, and corn flour. The mass percentage of each component is 40% of wood chips, 30% of corn cob flour, 13% of rice bran, 13% of bran, and 4% of corn flour. The water content of the above materials after mixing is 65%.

[0014] 2. Bottling

[0015] Using a fully automatic bottling machine requires uniform bottling and moderate compactness. 1100 plastic bottles charge 850 to 900 grams (including the weight of the plastic bottle).

[0016] 3. Sterilization

[0017] Generally, high-pressure sterilization is used, and the temperature is kept at 118-121°C for 90 minutes to kill all microorganisms and spores in the raw materials.

[0018] 4. Cooling

[0019] After the sterilization is finished, the sterilizing cart is pushed into the cooling room, and the temperature of the cooling room is set at 20°C. The cooling chamber is treated with air purification....

Embodiment 2

[0035] 1. Raw material mixing

[0036]The raw materials required for cultivation are sawdust, corn cob flour, rice bran, bran, and corn flour. The mass percentage of each component is 35% of sawdust, 32% of corn cob flour, 14% of rice bran, 14% of bran, and 5% of corn flour. The moisture content of the mixed material was 65%.

[0037] 2. Bottling

[0038] Using a fully automatic bottling machine requires uniform bottling and moderate compactness. 1100 plastic bottles charge 850 to 900 grams (including the weight of the plastic bottle).

[0039] 3. Sterilization

[0040] Generally, high-pressure sterilization is used, and the temperature is kept at 118-121°C for 90 minutes to kill all microorganisms and spores in the raw materials.

[0041] 4. Cooling

[0042] After the sterilization is finished, the sterilizing cart is pushed into the cooling room, and the temperature of the cooling room is set at 20°C. The cooling chamber is treated with air purification.

[0043] 5. V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com