Wet flue gas desulfurization method

A wet flue gas desulfurization and flue gas technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of long desulfurization absorption liquid treatment process, inability to be recycled, and large consumption of compressed air. Achieve the effect of saving equipment investment and operating costs, reducing processing costs, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

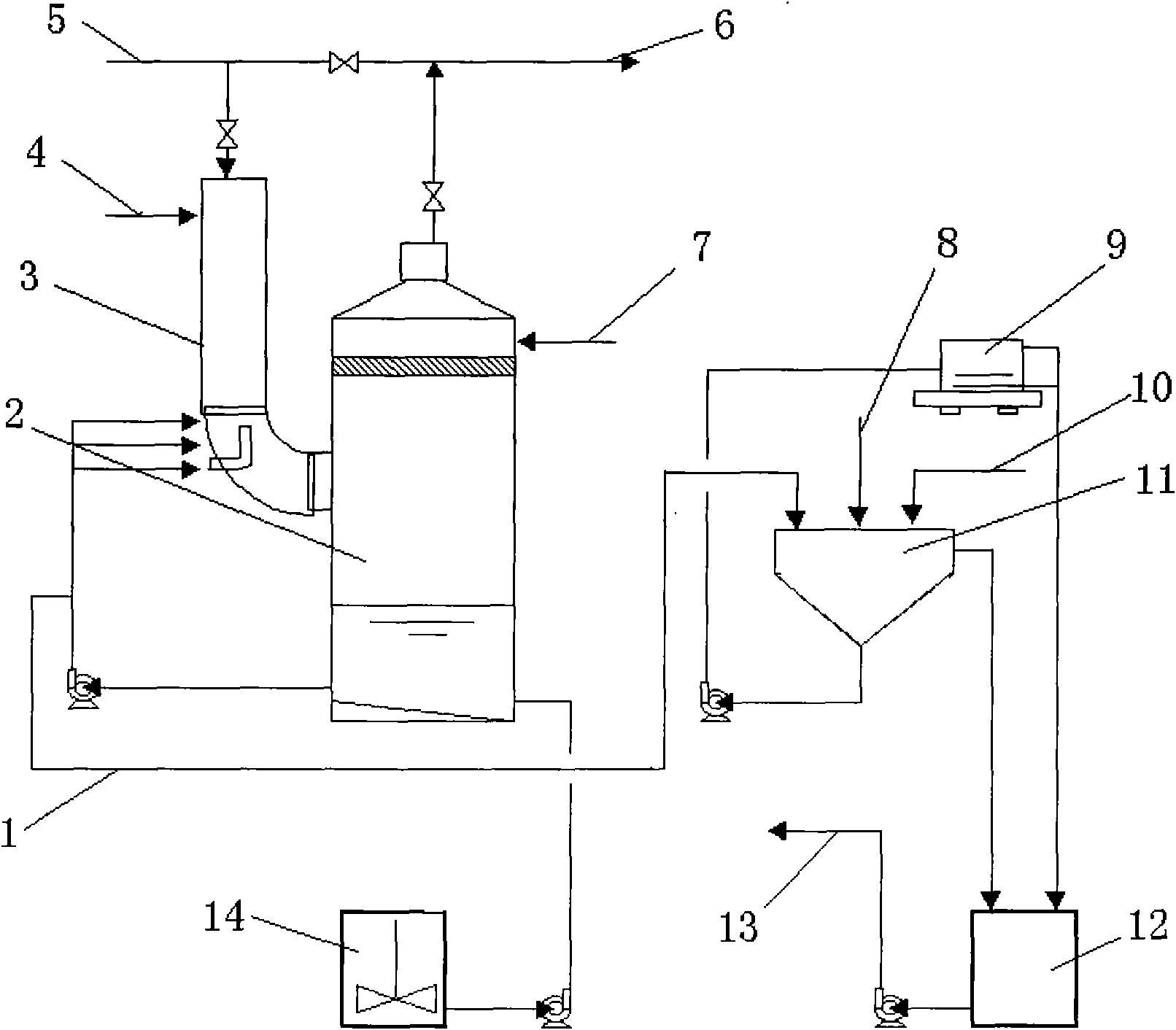

[0008] Such as figure 1 As shown, the absorption liquid in the absorption tower 2 is supplemented by the storage tank 14. The flue gas from the pipeline 5 is in contact with the circulating absorption liquid from the absorption tower 2 in the reverse nozzle 3, and the SO in the flue gas 2 React with the absorption liquid, the generated sulfite is dissolved or suspended in the absorption liquid, the dust in the flue gas is washed by the absorption liquid, and suspended in the absorption liquid; the flue gas after desulfurization and dust removal is discharged to the tail gas from the pipe 5 to the chimney , the purified water required by the reverse nozzle 3 is transported by the pipeline 4, and the pipeline 7 transports the flushing water to the absorption tower 2. A part of the circulating absorption liquid in the absorption tower 2 is sent to the purification settling tank 11 in the acid system through the pipeline 1 to react with the waste acid containing 5-15% sulfuric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com