Rounded corner cutting belt machine

A tape cutting machine and rounded corner technology, applied in the field of cutting machines, can solve the problems of high probability of error and damage, high cost of tape cutting machine, high control precision requirements, etc., and achieve the effect of convenient operation, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

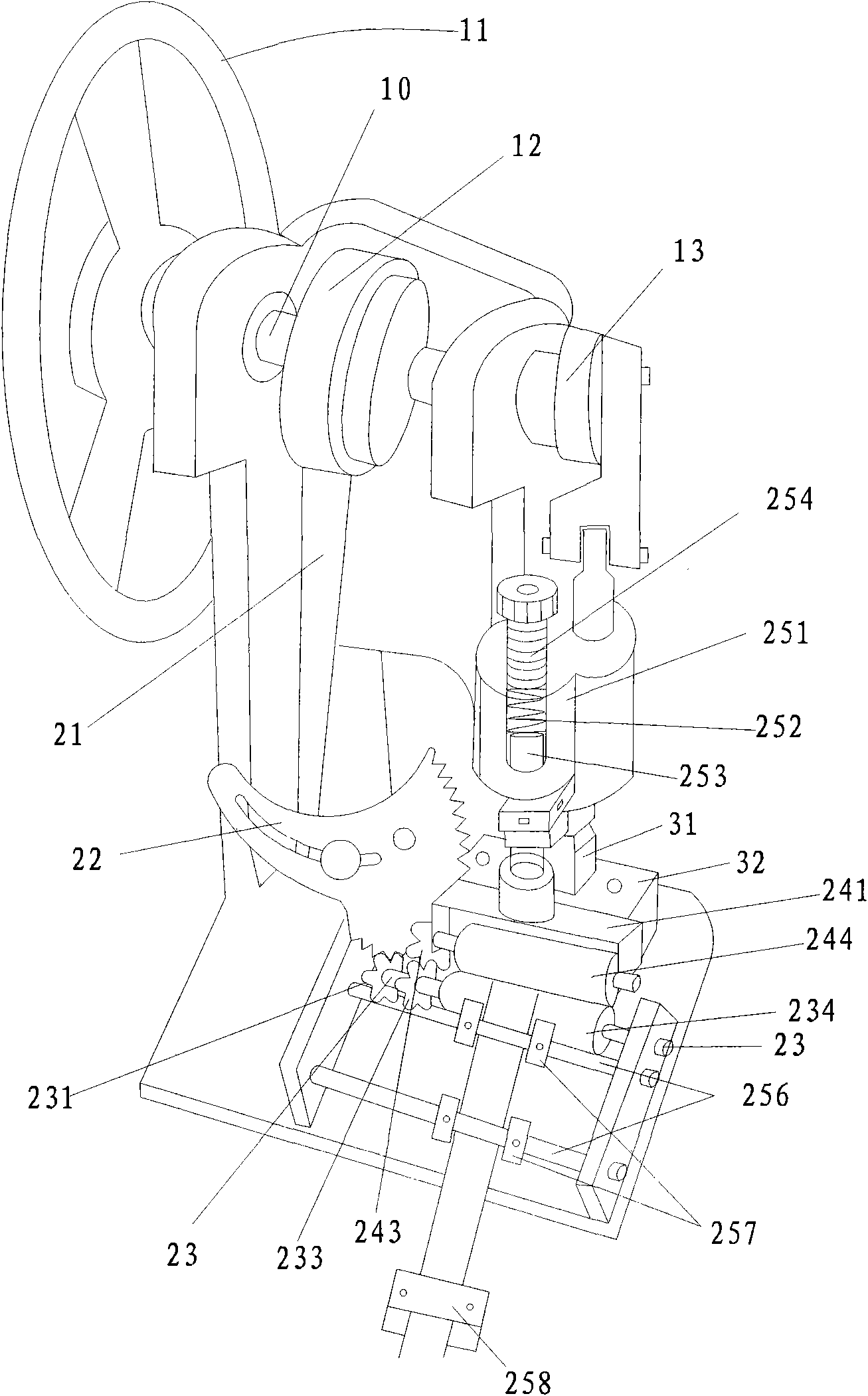

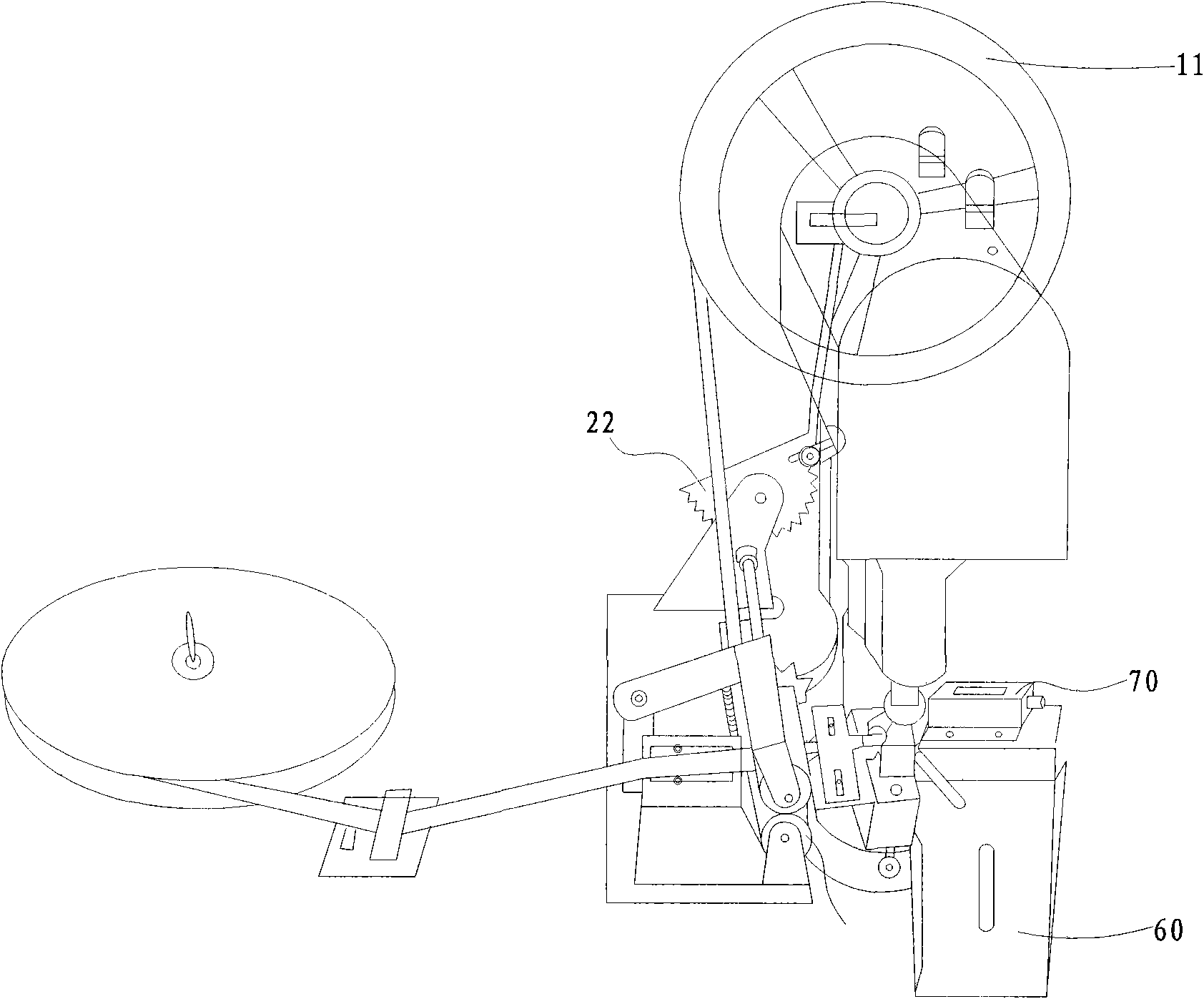

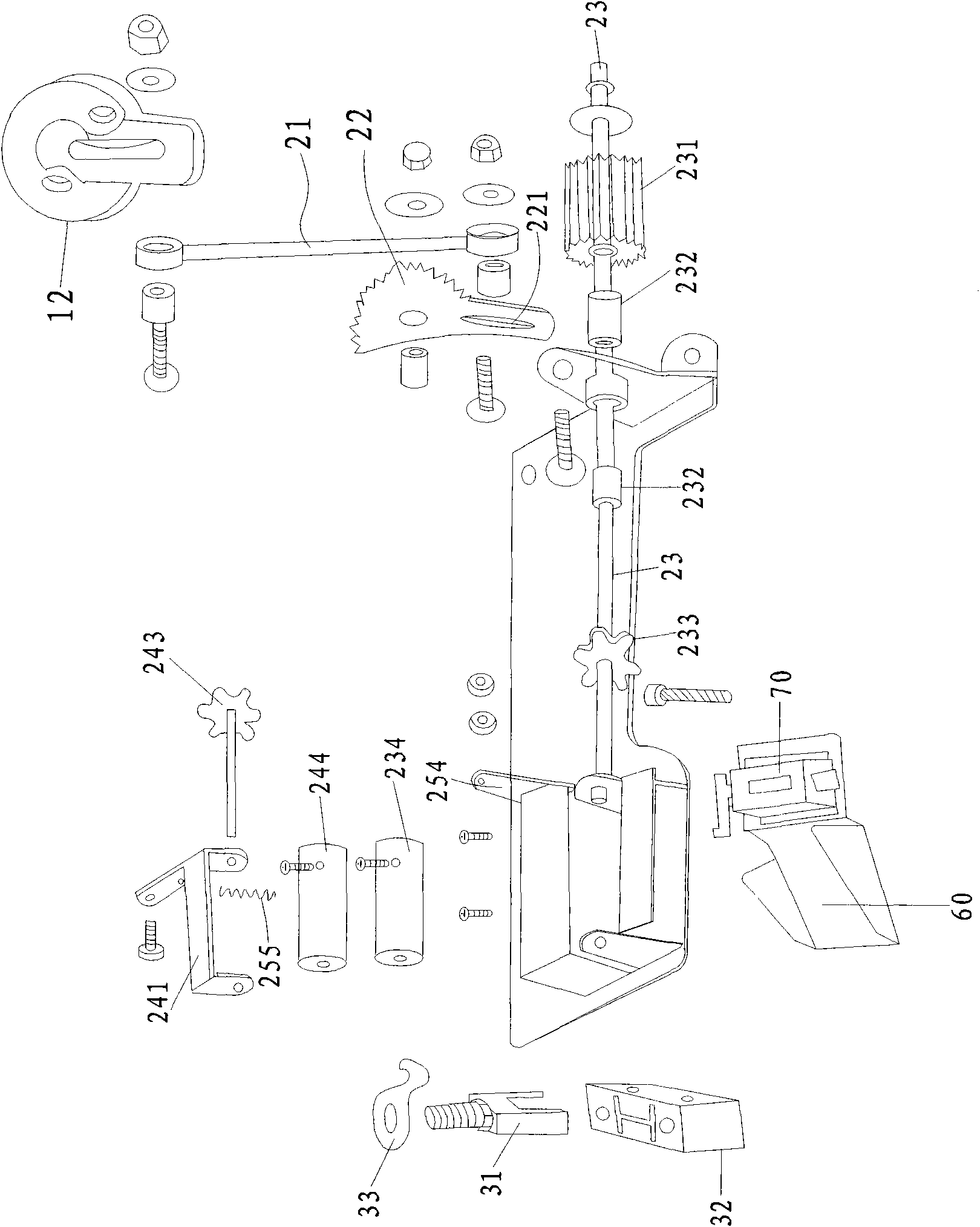

[0025] see figure 1 , figure 2 , image 3 , The fillet tape cutting machine of the present invention includes a transmission mechanism, a feeding mechanism and a cutter device.

[0026] The motor drives the pulley 11 on the main shaft 10, and the pulley 11 drives the coaxial feeding eccentric wheel 12 and the cutter eccentric wheel 13 to rotate synchronously, the feeding eccentric wheel 12 drives the feeding mechanism to convey materials, and the cutter eccentric wheel 13 drives the cutter device to cut materials.

[0027] The feeding mechanism includes a feeding eccentric wheel 12, wherein the feeding eccentric wheel 12 can adjust the size of the eccentricity by providing an adjustment groove on the body, or adjust the size of the ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com